Beyond Waste: How ABB Is Revolutionizing Manufacturing's Circular Economy

Manufacturing

2025-04-09 10:00:11

ABB is revolutionizing manufacturing sustainability by spearheading a groundbreaking approach to circular economy practices. The global technology leader is transforming industrial waste management through innovative solutions that help manufacturers dramatically reduce environmental impact and optimize resource utilization. By pioneering cutting-edge technologies and strategic circular design principles, ABB is enabling companies to reimagine their production processes. Their innovative approach goes beyond traditional waste reduction, focusing on creating closed-loop systems that minimize material waste, reduce carbon footprint, and drive economic efficiency. Through intelligent automation, advanced analytics, and sustainable engineering, ABB is empowering manufacturers to transition from linear to circular production models. This transformative strategy not only supports environmental conservation but also helps businesses unlock new opportunities for cost savings and competitive advantage in an increasingly sustainability-focused global market. The company's commitment to circularity represents a significant leap forward in industrial sustainability, demonstrating how technological innovation can be a powerful catalyst for positive environmental change. MORE...

Breaking: Luxshare Plots U.S. Manufacturing Shift to Outsmart Apple's Tariff Challenges

Manufacturing

2025-04-09 09:29:42

Luxshare, a key Apple supplier, is exploring strategic alternatives to mitigate the impact of U.S. tariffs by potentially relocating production beyond China's borders. During a recent analyst conference call on Wednesday, the company's chairwoman revealed that they are actively engaging with customers to discuss comprehensive manufacturing relocation strategies, which could include expanding production facilities in the United States. The move signals Luxshare's proactive approach to navigating the complex geopolitical and trade landscape, demonstrating the company's adaptability in response to ongoing economic challenges. By considering production shifts, Luxshare aims to maintain its competitive edge and provide flexible solutions for its high-profile clients like Apple. This potential geographical diversification of manufacturing could not only help the company reduce tariff-related expenses but also potentially create new job opportunities in alternative markets, including the United States. The discussions underscore the ongoing reconfiguration of global supply chains in response to international trade tensions. MORE...

Wheels of Fortune: THOR Industries Leads the Charge in Q4 Earnings Blowout

Manufacturing

2025-04-09 09:11:43

As the curtain falls on another earnings season, investors have a golden opportunity to uncover promising stocks and gain insights into how companies are navigating today's complex business landscape. Today, we'll dive into the performance of THOR Industries (NYSE:THO) and explore the broader trends in the automobile manufacturing sector during the fourth quarter. The end of earnings season serves as a strategic window for investors, offering a comprehensive view of corporate health and market adaptability. By examining companies like THOR Industries, we can better understand the challenges and opportunities facing the automotive manufacturing industry in the current economic climate. With careful analysis and a keen eye for emerging trends, savvy investors can leverage these quarterly reports to make informed investment decisions and identify potential growth opportunities in a rapidly evolving market. MORE...

Manufacturing's New Frontier: Connecticut Rises as Trump Tariff Tensions Spark Industrial Renaissance

Manufacturing

2025-04-09 09:00:00

Connecticut's innovative medical technology and assistive device sectors are gaining momentum, thanks to recent grant funding that highlights the state's commitment to groundbreaking research and development. Two remarkable projects have recently secured financial support, showcasing Connecticut's potential to drive technological advancements that improve quality of life. A cutting-edge tissue engineering device developed by local researchers and an innovative toilet lift designed to enhance mobility for individuals with physical challenges have both received crucial funding. These grants represent more than just financial support; they symbolize the state's dedication to fostering innovation and supporting technologies that can make a meaningful difference in people's lives. The tissue device, created by Connecticut-based researchers, demonstrates the state's prowess in advanced medical technology, while the toilet lift project underscores a commitment to developing practical solutions for accessibility. By investing in these forward-thinking projects, Connecticut is positioning itself as a hub for medical innovation and assistive technology. The funding not only supports individual researchers and inventors but also signals the state's broader vision of supporting technological solutions that can potentially transform healthcare and daily living for many individuals. As these projects move forward, they promise to not only advance technological capabilities but also improve the quality of life for numerous people, reflecting Connecticut's innovative spirit and commitment to solving real-world challenges. MORE...

Digital Dinosaurs: How Clinging to Legacy Systems Could Kill Your Business Overnight

Manufacturing

2025-04-09 08:00:24

In the rapidly evolving world of manufacturing, staying ahead means embracing technological transformation. Yuri Pilipenko, the visionary founder and CEO of OLSOM, is on a mission to help manufacturers break free from the constraints of outdated legacy systems and step into the future of smart manufacturing. Legacy systems have long been a bottleneck for industrial productivity, hindering efficiency, innovation, and competitiveness. Pilipenko understands that in today's digital age, manufacturers can no longer afford to rely on obsolete technologies that slow down operations and limit growth potential. OLSOM specializes in providing cutting-edge smart factory solutions that seamlessly bridge the gap between traditional manufacturing processes and modern digital technologies. By offering comprehensive system upgrades and intelligent technological interventions, the company empowers manufacturers to unlock unprecedented levels of operational efficiency, data-driven insights, and strategic agility. With a deep understanding of industrial challenges and a forward-thinking approach, Pilipenko and his team at OLSOM are committed to helping businesses transform their manufacturing ecosystems. Their tailored solutions not only modernize existing infrastructure but also create a foundation for continuous innovation and sustainable competitive advantage. The time to upgrade is now – and OLSOM is ready to guide manufacturers through their digital transformation journey. MORE...

iPhone's New Frontier: Apple Shifts Gears to India Amid China Trade Tensions

Manufacturing

2025-04-09 07:50:00

In a strategic move to navigate the challenging landscape of international trade, Apple is exploring significant expansion of its iPhone production capabilities in India. The tech giant is responding to escalating US tariffs by diversifying its manufacturing footprint, with a keen focus on reducing potential financial risks associated with exports to the United States. As geopolitical tensions and trade complexities continue to reshape global supply chains, Apple's decision to boost manufacturing in India represents a proactive approach to maintaining competitive pricing and supply chain resilience. The company is leveraging India's growing technological infrastructure and skilled workforce to create a robust alternative to its traditional Chinese manufacturing base. This strategic pivot not only helps Apple mitigate potential economic pressures but also aligns with the Indian government's "Make in India" initiative, which encourages domestic manufacturing and foreign investment. By increasing local production, Apple stands to benefit from potential tax incentives and reduced logistical complexities. Industry analysts suggest that this expansion could potentially transform India into a critical hub for Apple's global manufacturing strategy, offering the company greater flexibility in an increasingly unpredictable international trade environment. MORE...

Chrome Revolution: AMG Greenlights Groundbreaking US Manufacturing Facility

Manufacturing

2025-04-09 00:00:00

AMG Critical Materials Advances Strategic Initiatives with Board Approval

Amsterdam, April 9, 2025 - AMG Critical Materials N.V. (EURONEXT AMSTERDAM: AMG) is excited to announce a significant strategic development following the Management Board's comprehensive review and approval of key corporate initiatives.

The company's leadership has carefully evaluated and greenlit a forward-looking strategy that promises to enhance operational efficiency and drive long-term growth. This decision underscores AMG's commitment to innovation and strategic positioning in the critical materials sector.

While specific details of the approved plans are being carefully developed, the Management Board's proactive approach signals a promising trajectory for the company's future endeavors.

Investors and stakeholders can anticipate further communications detailing the scope and potential impact of these strategic initiatives in the coming weeks.

MORE...3D Printing Revolution: How Pratt & Whitney Is Transforming Engine Repair with Cutting-Edge Additive Manufacturing

Manufacturing

2025-04-09 00:00:00

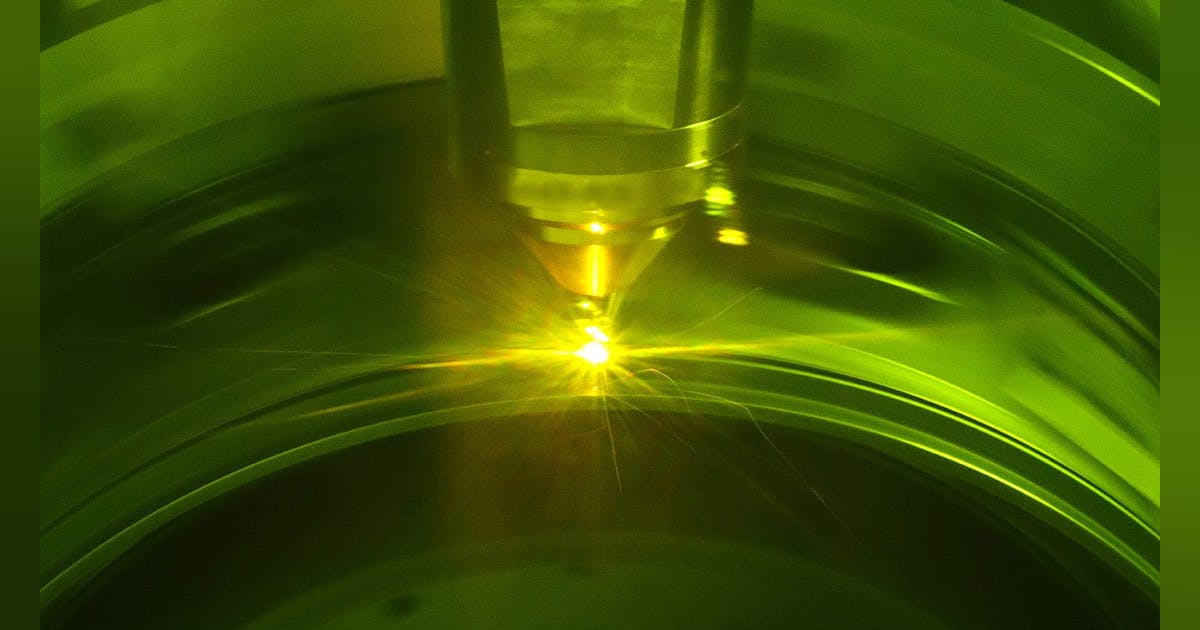

Revolutionizing Manufacturing: Cutting-Edge Repair Solution Slashes Processing Time In a groundbreaking advancement, a leading manufacturing company has unveiled an innovative additive repair solution that promises to transform industrial maintenance processes. This cutting-edge technology dramatically reduces processing time by an impressive 60%, marking a significant leap forward in manufacturing efficiency. The breakthrough centers on an advanced 3D printing technique called Directed Energy Deposition, which enables unprecedented precision and speed in component repair and restoration. By leveraging this state-of-the-art method, manufacturers can now address equipment wear and damage with remarkable speed and accuracy. This innovative approach not only accelerates repair workflows but also offers substantial cost savings and minimizes equipment downtime. Companies across various industries can now benefit from a more streamlined, technologically sophisticated repair process that enhances overall operational productivity. The new solution represents a pivotal moment in manufacturing technology, demonstrating how advanced 3D printing techniques can revolutionize traditional maintenance and repair strategies. As industries continue to seek more efficient and cost-effective solutions, this breakthrough stands at the forefront of technological innovation. MORE...

Silver Surge: How Companies Are Reinventing Workplace Strategy for an Aging Workforce

Manufacturing

2025-04-09 00:00:00

Navigating the Skilled Labor Challenge: Innovative Strategies for Workforce Sustainability In today's rapidly evolving manufacturing landscape, companies are confronting a critical challenge: retaining and replacing skilled workers. Forward-thinking manufacturers are developing comprehensive approaches that blend technological innovation, workplace design, and knowledge management to address this complex issue. The key to success lies in a multi-faceted strategy that encompasses three primary dimensions: 1. Physical Workplace Transformation Modern manufacturers are reimagining workplace environments to attract and retain top talent. Ergonomic workstations, adaptive equipment, and intelligent workspace designs create more comfortable and efficient working conditions that appeal to skilled professionals. 2. Cutting-Edge Technological Support Advanced technologies are revolutionizing workforce management. Smart assistive tools, augmented reality training systems, and intuitive digital platforms help bridge skill gaps and make complex tasks more accessible to workers of varying experience levels. 3. Strategic Knowledge Transfer Implementing structured mentorship programs and comprehensive knowledge-sharing platforms ensures that critical expertise is systematically captured and transmitted across generations of workers. This approach preserves institutional knowledge and creates a continuous learning culture. By embracing these integrated strategies, manufacturers can transform workforce challenges into opportunities for innovation, productivity, and long-term organizational resilience. MORE...

Robots on the Factory Floor: How Autonomous Mobile Robots Are Revolutionizing Manufacturing

Manufacturing

2025-04-09 00:00:00

Autonomous Mobile Robots (AMRs) are revolutionizing manufacturing automation by offering an incredibly versatile and user-friendly solution for businesses looking to streamline their operations. However, the key to successful AMR implementation lies in strategic planning and careful selection. Manufacturers must approach AMR integration with a thoughtful mindset, carefully identifying the most suitable tasks and preparing their facilities to maximize the potential of these intelligent robotic systems. By conducting a thorough assessment of workflow challenges and operational requirements, companies can unlock the transformative power of AMR technology. The true strength of AMRs lies in their adaptability. Unlike traditional fixed automation systems, these intelligent robots can seamlessly navigate dynamic work environments, quickly adjusting to changing production demands and facility layouts. This flexibility allows manufacturers to optimize their processes with minimal disruption and maximum efficiency. Success with AMRs isn't just about purchasing the technology—it's about creating a comprehensive implementation strategy. Facilities must be carefully evaluated for potential obstacles, workflow patterns must be analyzed, and staff must be trained to work collaboratively with these advanced robotic assistants. When approached strategically, AMRs can become a game-changing solution that enhances productivity, reduces manual labor, and drives significant operational improvements across manufacturing environments. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238