Tech Titans Unite: MSU and Apple Forge Detroit's Future with Cutting-Edge Manufacturing Academy

Manufacturing

2025-04-03 12:00:00

Michigan State University is thrilled to renew its strategic partnership with Apple, launching an innovative initiative designed to transform and elevate small and medium-sized manufacturing enterprises across the nation. This collaborative program aims to provide cutting-edge support and resources that will help these businesses optimize their operations, boost productivity, and drive technological advancement in the manufacturing sector. By combining Michigan State University's academic expertise with Apple's technological prowess, the partnership promises to deliver comprehensive solutions that empower manufacturers to compete more effectively in today's rapidly evolving industrial landscape. The program represents a significant commitment to strengthening American manufacturing capabilities and fostering economic growth through strategic innovation and targeted support. MORE...

Future of Firefighting: Pierce Manufacturing Unveils Cutting-Edge Apparatus at FDIC 2025

Manufacturing

2025-04-03 12:00:00

Pierce Manufacturing is set to ignite excitement at the upcoming Fire Department Instructors Conference (FDIC) 2025, showcasing cutting-edge fire apparatus and groundbreaking technological innovations. The event, scheduled for April 9-11 in Indianapolis, Indiana, will provide firefighting professionals with an exclusive look at Pierce's latest advancements in emergency response equipment. Attendees can expect to explore state-of-the-art fire trucks, revolutionary safety technologies, and innovative design solutions that are pushing the boundaries of firefighting capabilities. Pierce Manufacturing continues to demonstrate its commitment to supporting first responders by delivering top-tier equipment that enhances performance, safety, and operational efficiency. The FDIC conference represents a premier opportunity for fire service professionals to discover the most advanced apparatus and technologies in the industry, with Pierce Manufacturing at the forefront of innovation. Firefighters, emergency managers, and industry experts will converge to witness firsthand the future of fire apparatus design and technological integration. MORE...

Breaking: FlashPCB Revolutionizes Production with Cutting-Edge Manufacturing Upgrade

Manufacturing

2025-04-03 10:20:18

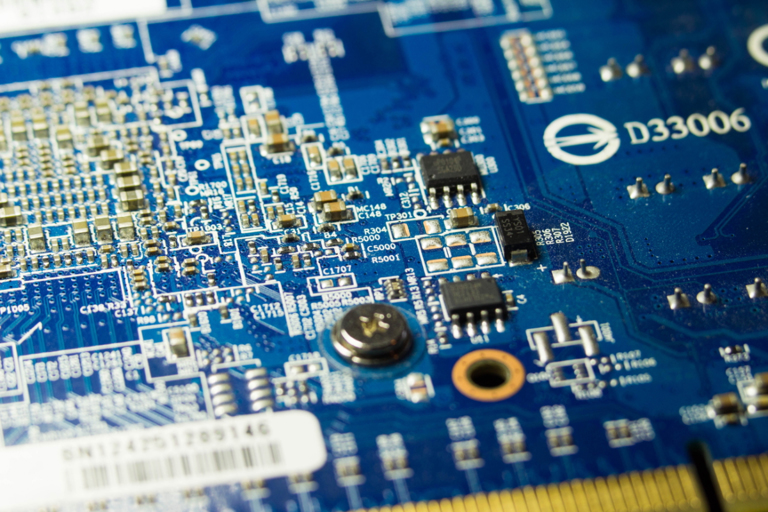

In a strategic move to enhance its manufacturing capabilities, a leading US quick-turn PCB assembly provider has recently invested in cutting-edge technology. The company has acquired a state-of-the-art 1 Click SMT Drymaster 555L, a significant upgrade to its production infrastructure. Don Dennison, President of PIT – Equipment Services, LLC, played a pivotal role in facilitating this important equipment purchase. The new Drymaster 555L is expected to boost the provider's efficiency, precision, and overall production capacity, positioning the company at the forefront of PCB assembly technology. This investment underscores the provider's commitment to continuous improvement and maintaining a competitive edge in the rapidly evolving electronics manufacturing landscape. MORE...

Can Trump's Trade Gambit Resurrect America's Industrial Heartland?

Manufacturing

2025-04-03 09:02:51

President Promises Economic Revival Through Strategic Trade Policies In a bold declaration of economic optimism, the president asserted that his administration's trade strategies are set to spark a dramatic resurgence of manufacturing and job opportunities across the nation. With unwavering confidence, he painted a picture of economic renewal, suggesting that factories will soon hum with activity and employment rates will surge. The president's vision centers on a comprehensive approach to trade that aims to revitalize domestic industries and create a more robust economic landscape. By implementing targeted policies designed to protect and promote American manufacturing, he believes the country can reclaim its industrial strength and provide meaningful employment for millions of workers. While critics may question the feasibility of such ambitious claims, the administration remains steadfast in its commitment to transforming the economic narrative. The promise of "jobs roaring back" represents more than just political rhetoric—it's a strategic blueprint for economic recovery and long-term prosperity. As the nation watches and waits, the potential impact of these trade policies continues to generate both excitement and skepticism. Only time will reveal the true effectiveness of this bold economic approach. MORE...

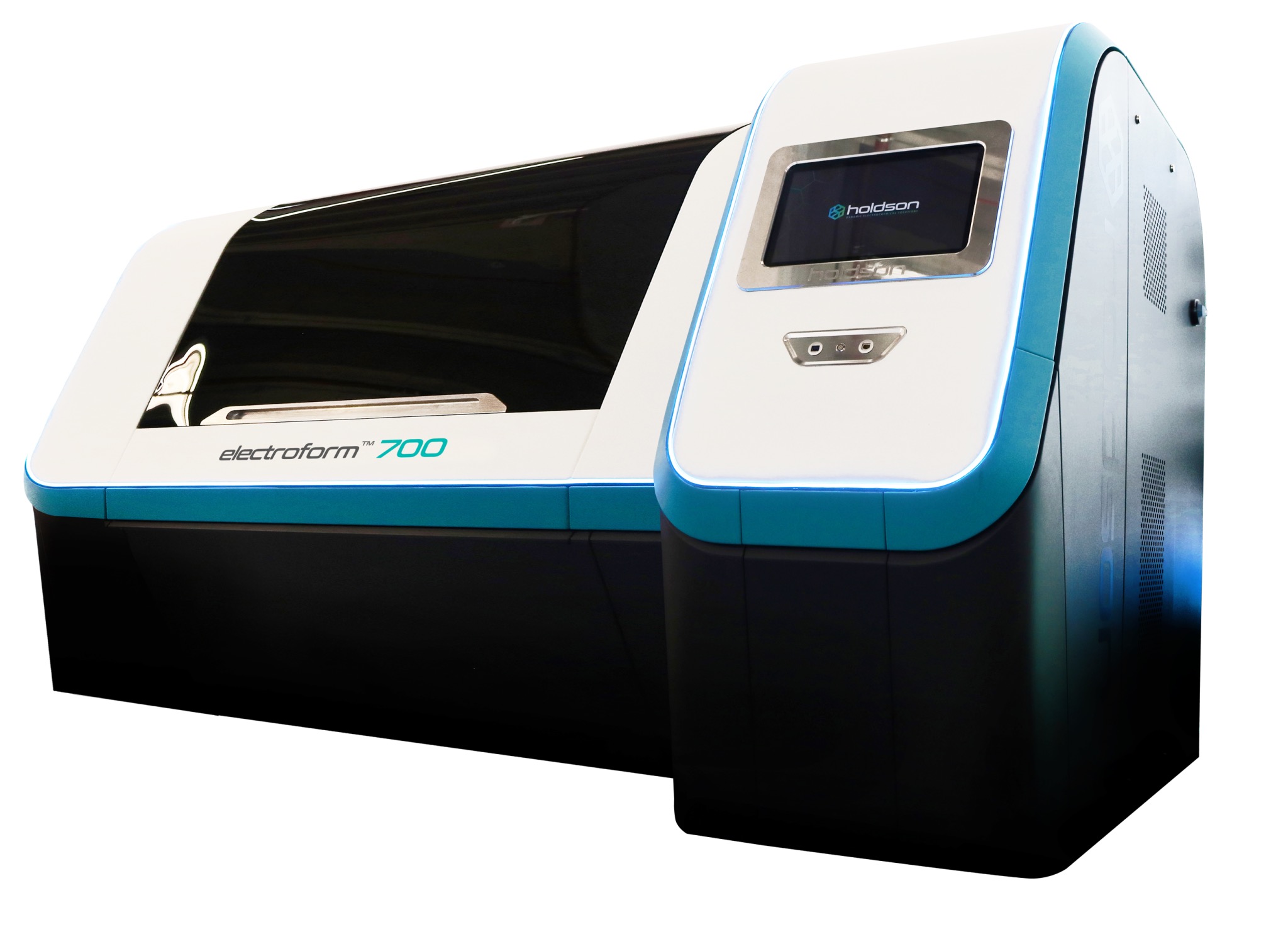

Revolutionizing 3D Printing: Additive Manufacturing Solutions Expands Capabilities with Holdson's Cutting-Edge Electroform Technology

Manufacturing

2025-04-03 08:53:02

Revolutionizing Surface Quality: Holdson and Additive Manufacturing Solutions Break New Ground In the cutting-edge world of advanced manufacturing, Holdson and Additive Manufacturing Solutions are pushing the boundaries of surface technology through their groundbreaking electroform approach. This innovative technique represents a significant leap forward in precision engineering, offering unprecedented improvements in surface quality and performance. By leveraging state-of-the-art electroforming technology, the collaboration between these industry leaders is transforming how manufacturers approach surface refinement. Their unique method allows for microscopic-level precision, creating surfaces with exceptional smoothness, durability, and structural integrity that were previously unimaginable. The electroform process enables engineers to develop components with remarkable detail and consistency, opening up new possibilities across multiple industries, from aerospace and medical devices to high-performance electronics. By meticulously controlling the metal deposition process, Holdson and Additive Manufacturing Solutions are setting new standards in manufacturing excellence. Professionals and engineers are taking notice of this revolutionary technique, recognizing its potential to dramatically enhance product performance and reliability. As manufacturing continues to evolve, this innovative approach promises to be a game-changer in surface engineering. MORE...

High-Tech Manufacturing Boom: Collaborative Efforts Spark Innovation in Virginia's New River Valley

Manufacturing

2025-04-03 08:10:00

Emerging from the innovative landscape of the CHIPS and Science Act of 2022, a dynamic regional consortium has taken shape through a competitive federal grant process. The U.S. Economic Development Authority sparked a nationwide initiative, inviting diverse groups to conceptualize and develop cutting-edge tech hubs across multiple industries. This strategic approach aims to foster technological innovation and regional economic growth by empowering local communities to become centers of technological advancement and entrepreneurship. MORE...

Green Manufacturing Revolution: SWREL's Hybrid Projects Set to Transform Renewable Energy Landscape

Manufacturing

2025-04-03 08:00:00

Sterling and Wilson Renewable Energy Pioneers Expansion into Wind Engineering, Procurement, and Construction (EPC), Sparking New Manufacturing Opportunities In a strategic move that promises to reshape the renewable energy landscape, Sterling and Wilson Renewable Energy is broadening its horizons by venturing into wind EPC services. This bold expansion is set to catalyze manufacturing demand across multiple critical sectors, including wind turbines, solar modules, and transmission infrastructure. The company's innovative approach signals a comprehensive commitment to sustainable energy solutions, leveraging its extensive expertise to create integrated renewable energy ecosystems. By diversifying into wind EPC, Sterling and Wilson is not just expanding its service portfolio, but also driving significant economic and technological momentum in the green energy sector. This strategic expansion is expected to unlock new manufacturing opportunities, stimulate industrial growth, and accelerate the transition towards more sustainable and diversified renewable energy infrastructure. The move positions Sterling and Wilson as a forward-thinking leader in the rapidly evolving clean energy market. MORE...

Trade War Tactics: Could Trump's Tariff Gambit Unleash America's Manufacturing Phoenix?

Manufacturing

2025-04-03 07:46:30

In the complex landscape of global trade, Donald Trump's aggressive tariff policies have sent shockwaves through international markets, creating both challenges and potential opportunities for emerging economies like India. As the world's economic powerhouses engage in a high-stakes trade chess match, India stands at a critical juncture, poised to potentially transform disruption into strategic advantage. Trump's sweeping tariffs, particularly those targeting China and other major trading partners, have fundamentally reshaped global trade dynamics. While many nations have viewed these policies as a source of uncertainty, India sees a unique window for economic repositioning. The disruption in traditional trade routes and supply chains presents an unprecedented opportunity for Indian businesses and policymakers to reimagine their global economic strategy. Key sectors like manufacturing, technology, and agriculture could potentially benefit from this shifting landscape. By offering competitive alternatives to traditional manufacturing hubs and leveraging its skilled workforce, India could attract multinational companies seeking to diversify their supply chains away from traditional markets. However, seizing this opportunity requires strategic planning, robust infrastructure development, and proactive policy-making. The Indian government must create an attractive investment environment, streamline regulatory processes, and develop targeted strategies to capitalize on the emerging global trade reconfiguration. As the international economic order continues to evolve, India's ability to adapt, innovate, and position itself strategically will be crucial in determining whether it can truly transform Trump's trade disruption into a catalyst for economic growth and global competitiveness. MORE...

Tech Titan's Power Move: Industry Veteran Steers Hexagon's Manufacturing Revolution

Manufacturing

2025-04-03 06:17:00

Hexagon Taps Former ABB Executive Andreas Renulf to Lead Manufacturing Technology Division

Hexagon has made a strategic leadership move by appointing Andreas Renulf, a seasoned executive from ABB, to helm its manufacturing technology division. Renulf brings extensive expertise in robotics and automation, positioning Hexagon to accelerate its technological innovation and market leadership.

With a proven track record at ABB, Renulf is expected to drive significant advancements in Hexagon's manufacturing technology strategies. His deep understanding of industrial automation and robotics will be crucial in enhancing the company's competitive edge and technological capabilities.

The transition marks an important milestone for Hexagon, signaling a strong commitment to cutting-edge manufacturing solutions. Renulf's appointment underscores the company's vision to push boundaries in robotics, automation, and advanced manufacturing technologies.

Industry experts anticipate that Renulf's leadership will catalyze transformative changes within Hexagon's manufacturing technology division, potentially setting new benchmarks for innovation and operational excellence.

MORE...Trade War Brewing: Trump's Tariff Gambit Sparks Manufacturing Showdown

Manufacturing

2025-04-03 01:23:25

In a bold and controversial move that sent shockwaves through global markets, President Donald Trump unveiled sweeping new tariffs on Wednesday that could dramatically reshape international trade dynamics. The unprecedented economic strategy targets major trading partners with substantial import taxes, including a hefty 34% levy on Chinese imports and a significant 20% tariff on European Union goods. These aggressive trade measures have the potential to fundamentally disrupt the intricate web of global economic relationships, raising serious concerns about potential retaliatory actions and the risk of escalating trade tensions. Economists and international trade experts warn that such wide-ranging tariffs could trigger a cascade of economic consequences, potentially unraveling decades of carefully constructed international trade agreements. The announcement signals a dramatic shift in U.S. trade policy, with Trump demonstrating his commitment to an "America First" approach that prioritizes domestic economic interests over established international trade norms. By imposing these substantial tariffs, the administration aims to protect American industries and workers, though the long-term economic implications remain uncertain and hotly debated. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238