Digital Dinosaurs: How Clinging to Legacy Systems Could Kill Your Business Overnight

Manufacturing

2025-04-09 08:00:24Content

In the rapidly evolving world of manufacturing, staying ahead means embracing technological transformation. Yuri Pilipenko, the visionary founder and CEO of OLSOM, is on a mission to help manufacturers break free from the constraints of outdated legacy systems and step into the future of smart manufacturing.

Legacy systems have long been a bottleneck for industrial productivity, hindering efficiency, innovation, and competitiveness. Pilipenko understands that in today's digital age, manufacturers can no longer afford to rely on obsolete technologies that slow down operations and limit growth potential.

OLSOM specializes in providing cutting-edge smart factory solutions that seamlessly bridge the gap between traditional manufacturing processes and modern digital technologies. By offering comprehensive system upgrades and intelligent technological interventions, the company empowers manufacturers to unlock unprecedented levels of operational efficiency, data-driven insights, and strategic agility.

With a deep understanding of industrial challenges and a forward-thinking approach, Pilipenko and his team at OLSOM are committed to helping businesses transform their manufacturing ecosystems. Their tailored solutions not only modernize existing infrastructure but also create a foundation for continuous innovation and sustainable competitive advantage.

The time to upgrade is now – and OLSOM is ready to guide manufacturers through their digital transformation journey.

Revolutionizing Manufacturing: The Critical Path to Digital Transformation in Smart Factories

In the rapidly evolving landscape of industrial technology, manufacturers face an unprecedented challenge: modernize or risk becoming obsolete. The digital revolution is not just knocking at the door—it's breaking through the walls of traditional manufacturing paradigms, demanding immediate and strategic technological upgrades that can redefine operational efficiency and competitive advantage.Navigating the Digital Frontier: Why Legacy Systems Are Holding Your Business Back

The Hidden Costs of Technological Stagnation

Modern manufacturing environments are increasingly complex ecosystems that require sophisticated technological integration. Legacy systems, while once revolutionary, now represent significant operational bottlenecks that can dramatically impede productivity and innovation. These outdated technological infrastructures create multiple points of inefficiency, from slow data processing to limited scalability and increased vulnerability to cybersecurity threats. Manufacturers who continue to rely on antiquated technological frameworks are essentially operating with one hand tied behind their back. The inability to seamlessly integrate advanced analytics, real-time monitoring, and adaptive manufacturing processes means missed opportunities for optimization, reduced competitive edge, and potential revenue loss.Smart Factory Technologies: The New Competitive Landscape

The emergence of smart factory technologies represents a quantum leap in manufacturing capabilities. Advanced systems powered by artificial intelligence, machine learning, and Internet of Things (IoT) technologies enable unprecedented levels of operational intelligence. These technologies transform traditional manufacturing floors into dynamic, self-optimizing environments that can predict maintenance needs, adjust production parameters in real-time, and dramatically reduce operational inefficiencies. By implementing cutting-edge smart factory solutions, manufacturers can achieve remarkable improvements in productivity, quality control, and resource allocation. The ability to collect and analyze granular operational data allows for more informed decision-making, predictive maintenance, and strategic planning.Overcoming Implementation Challenges

While the benefits of digital transformation are clear, many manufacturers hesitate due to perceived complexity and potential disruption. However, strategic partners like OLSOM specialize in providing seamless technological migration pathways that minimize operational interruption and maximize return on investment. The implementation process involves comprehensive assessment, customized solution design, and phased technological integration. Expert consultants work closely with organizations to understand unique operational requirements, developing tailored strategies that align technological upgrades with specific business objectives.The Economic Imperative of Digital Modernization

Digital transformation is no longer an optional strategic initiative—it's an economic imperative. Companies that successfully modernize their technological infrastructure can expect significant returns, including reduced operational costs, enhanced product quality, improved worker safety, and increased overall competitiveness. The investment in smart factory technologies represents a forward-looking approach that positions manufacturers to adapt quickly to changing market demands, technological innovations, and global economic shifts. By embracing digital transformation, businesses can create more agile, responsive, and efficient manufacturing ecosystems.Future-Proofing Manufacturing Through Strategic Innovation

The journey toward technological modernization is not about replacing entire systems overnight but implementing strategic, incremental improvements. Partners like OLSOM provide the expertise and technological solutions necessary to navigate this complex transformation, ensuring manufacturers can evolve without experiencing significant operational disruptions. As global manufacturing landscapes continue to change rapidly, those who proactively invest in smart technologies will be best positioned to lead, innovate, and thrive in an increasingly competitive global marketplace.RELATED NEWS

Manufacturing

Biotech Powerhouses Unite: J&J and Legend's $150M Gamble to Supercharge Cancer Treatment Production

2025-03-13 13:19:46

Manufacturing

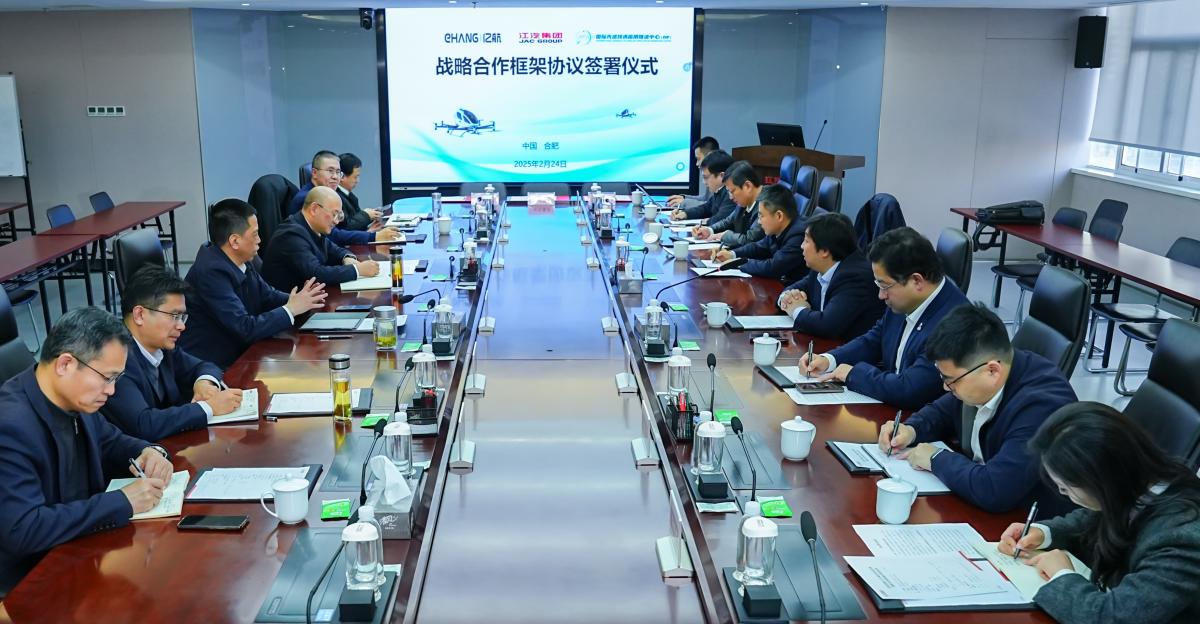

Flying Future: EHang Joins Forces with JAC and Guoxian to Revolutionize Urban Air Mobility in Hefei

2025-02-25 04:59:00