Manufacturing's Lifeline Cut: Trump and DOGE's Controversial Defunding Bombshell

Manufacturing

2025-04-02 23:59:39

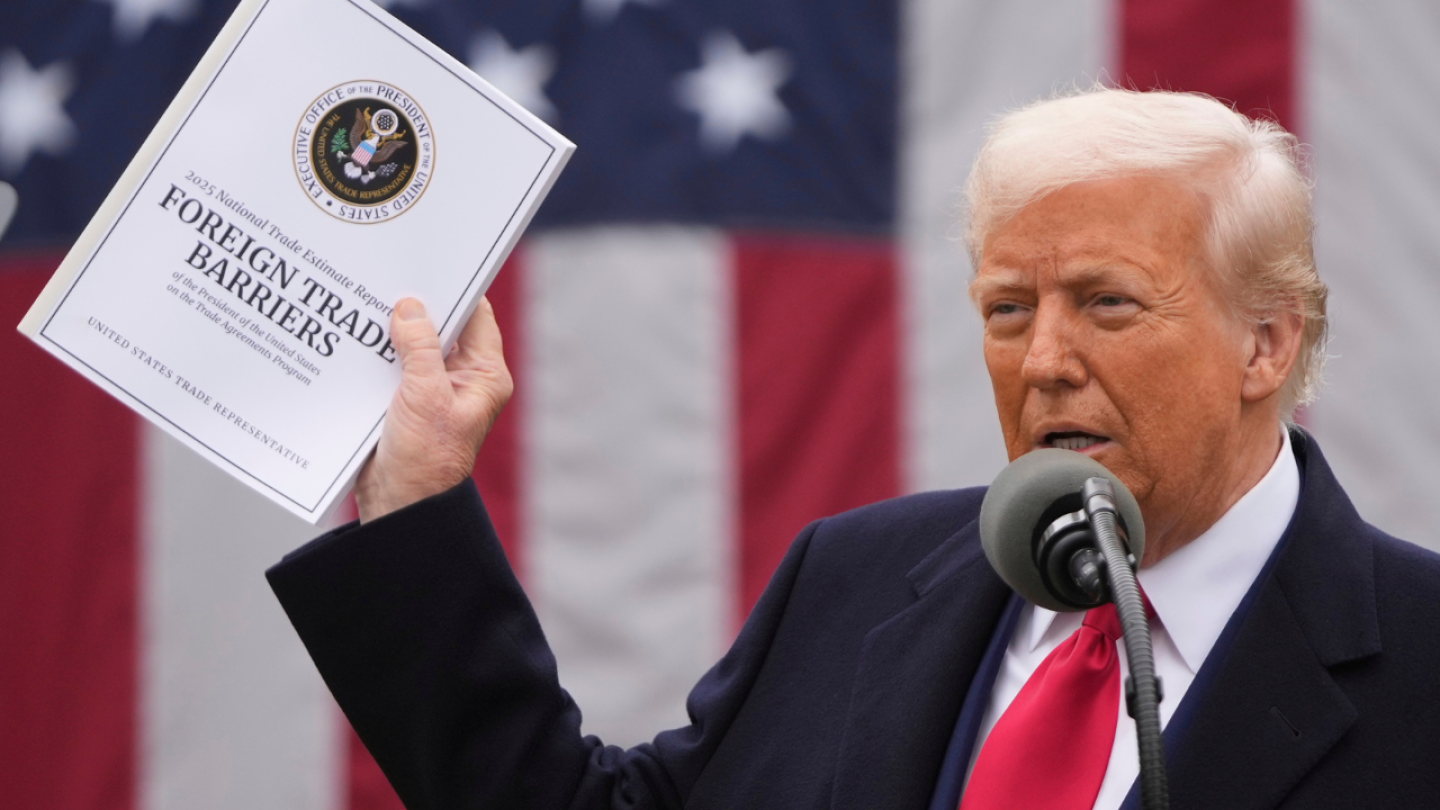

In a striking contradiction, President Donald Trump claims that imposing tariffs will revitalize American manufacturing, yet his administration simultaneously undermined critical support systems for domestic industries. Just hours before announcing new import taxes, the White House quietly reduced funding for manufacturing assistance centers designed to help U.S. companies compete and grow. The move highlights a complex and seemingly inconsistent approach to industrial policy. While Trump has consistently championed protectionist trade measures as a strategy to bolster domestic production, the cuts to support centers suggest a potential disconnect between rhetoric and practical support for American manufacturers. These manufacturing assistance centers play a crucial role in providing small and medium-sized businesses with technical expertise, strategic guidance, and resources needed to innovate and remain competitive in a global marketplace. By reducing their support, the administration may be inadvertently weakening the very industrial base it claims to be protecting. The timing of these funding cuts, coinciding with new tariff announcements, raises questions about the administration's commitment to truly supporting American manufacturing beyond symbolic trade measures. MORE...

Tariff Tango: Can American Factories Dance to the Economic Rhythm?

Manufacturing

2025-04-02 23:41:36

Trump's Tariff Strategy: A Double-Edged Sword for American Manufacturing President Trump's recent push for increased tariffs aims to bolster U.S. manufacturing, promising a renaissance for domestic production. However, the reality on the ground tells a more complex story. Despite the administration's optimistic rhetoric, American manufacturers face significant challenges that could undermine the potential benefits of trade protectionism. The primary obstacles are twofold: a critical shortage of skilled workers and limited factory capacity. Many industries are struggling to find qualified workers with the technical expertise needed to drive advanced manufacturing. Vocational training programs and workforce development have not kept pace with the rapidly evolving technological landscape. Moreover, existing manufacturing infrastructure is stretched thin. Factories are operating near maximum capacity, and the investment required to expand facilities and retool production lines represents a substantial financial hurdle for many companies. This means that while tariffs might create opportunities, the manufacturing sector may not be fully prepared to capitalize on them immediately. The disconnect between policy ambitions and industrial readiness highlights the nuanced challenges of revitalizing American manufacturing in a global economic environment. While protective trade measures might seem appealing, sustainable growth requires a more comprehensive approach that addresses workforce development, technological innovation, and strategic infrastructure investment. MORE...

Tariff Tango: Nike's Strategic Exodus from Vietnam Sparks Trade War Tensions

Manufacturing

2025-04-02 23:09:19

Nike's key manufacturing powerhouses, Vietnam and China, are bracing for significant economic challenges as they face potentially steep import tariff increases under the Trump administration's latest trade policy proposals. These two countries, which serve as critical production hubs for the global sportswear giant, could see their manufacturing costs and international competitiveness dramatically impacted by the proposed tariff rates. The potential new tariffs represent a substantial threat to Nike's intricate global supply chain, which has long relied on the cost-effective manufacturing capabilities of Vietnam and China. With these countries being primary sources of Nike's footwear and apparel production, the proposed trade measures could force the company to reevaluate its manufacturing strategies and potentially seek alternative production locations. As trade tensions continue to simmer between the United States and these Asian manufacturing giants, Nike finds itself navigating a complex landscape of geopolitical and economic uncertainties. The company will need to carefully strategize to mitigate potential financial impacts and maintain its competitive edge in the global sportswear market. MORE...

Trade War Threat: How Trump's EU Tariffs Could Shake Up Pharma Supply Chains

Manufacturing

2025-04-02 22:01:22

In a bold move from the White House Rose Garden, President Donald Trump's latest trade strategy could send shockwaves through the pharmaceutical industry. The newly announced reciprocal tariffs are poised to potentially disrupt operations for some of the nation's most prominent drug manufacturers. The unexpected policy shift threatens to create significant challenges for major pharmaceutical companies, potentially impacting their global supply chains and manufacturing costs. As the administration continues to leverage trade as a strategic tool, drug makers are now facing the prospect of navigating a complex new economic landscape. With these tariffs on the horizon, industry leaders are closely examining the potential financial implications and exploring strategies to mitigate potential economic pressures. The announcement underscores the Trump administration's commitment to reshaping international trade relationships, even in sectors as critical as healthcare and pharmaceuticals. MORE...

Economic Boost: Georgia Welcomes Cutting-Edge Manufacturing Plant, Promises Workforce Expansion

Manufacturing

2025-04-02 21:47:36

In a significant economic boost for Georgia, Governor Brian P. Kemp unveiled exciting plans for a groundbreaking manufacturing facility set to open in Smyrna. Flock Safety, a cutting-edge technology company headquartered in the Peach State, is poised to bring innovative license plate recognition solutions to the region. The announcement marks a pivotal moment for local economic development, promising new job opportunities and technological advancement. Flock Safety, known for its sophisticated security and surveillance technologies, will establish a state-of-the-art manufacturing hub that underscores Georgia's commitment to attracting forward-thinking businesses. Governor Kemp's enthusiasm was palpable as he highlighted the strategic importance of this new facility, which represents another milestone in Georgia's growing reputation as a premier destination for tech and manufacturing enterprises. The Smyrna location is expected to become a centerpiece of the company's expansion efforts, signaling strong confidence in the local workforce and business environment. MORE...

Trade War Tremors: How Manufacturers Are Preparing for Economic Aftershocks

Manufacturing

2025-04-02 21:39:27

In a swift response to the latest trade developments, Jay Timmons, President and CEO of the National Association of Manufacturers, has issued a compelling statement addressing the complex landscape of newly announced tariffs. The manufacturing sector finds itself at a critical crossroads, with industry leaders working diligently to unravel the potential impact of these trade measures. Timmons emphasized the unprecedented stakes facing American manufacturers, highlighting the intricate challenges that lie ahead. As businesses across the United States scramble to understand the nuanced implications of these tariffs, the manufacturing community remains vigilant and adaptive. The announcement signals a potentially transformative moment for industrial strategy and international trade relations. While the full ramifications are still being assessed, manufacturers are preparing to navigate this complex economic terrain with strategic precision and resilience. The coming weeks will be crucial in determining how these tariffs will reshape the manufacturing landscape. MORE...

Made in America: Trump's Bold Tariff Gambit to Revive Manufacturing Heartland

Manufacturing

2025-04-02 21:17:14

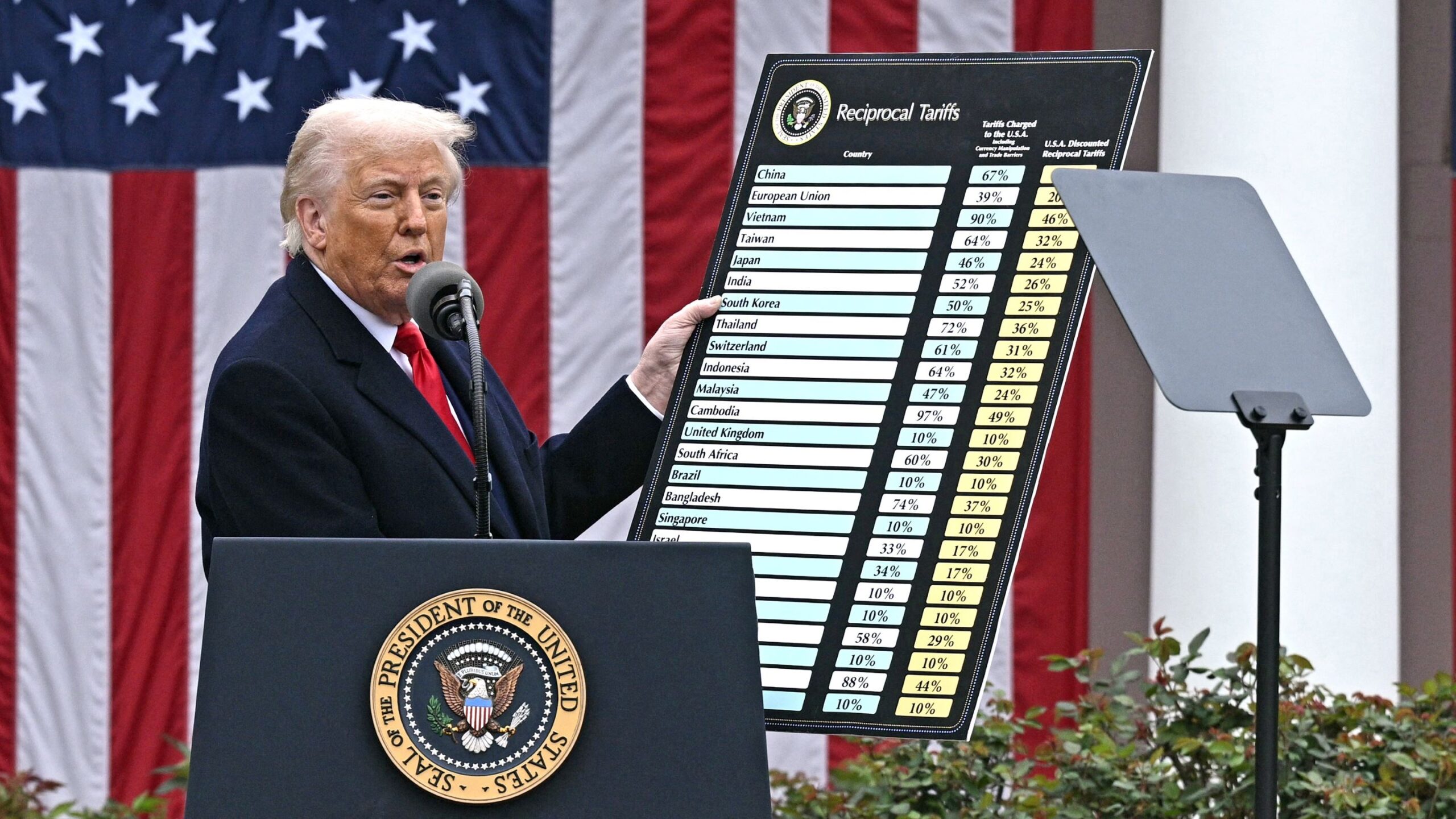

In a bold move that sent shockwaves through global trade circles, President Donald Trump unveiled a sweeping new tariff strategy on April 2, introducing a comprehensive import tax policy. The administration's plan includes a baseline 10% tariff on imports from all countries, with even steeper rates targeted at nations maintaining significant trade surpluses with the United States. This aggressive trade approach signals the Trump administration's commitment to reshaping international economic relationships and protecting domestic industries. By implementing a uniform baseline tariff and imposing additional penalties on countries with trade imbalances, the president aims to level the playing field for American businesses and workers. The announcement represents a dramatic escalation in the administration's ongoing efforts to address what it perceives as unfair international trade practices. Economists and trade experts are closely watching the potential ripple effects of this unprecedented tariff strategy, which could dramatically alter global trade dynamics in the coming months. MORE...

Trade Showdown: Trump's Bold Tariff Gambit Sparks Economic Tremors

Manufacturing

2025-04-02 21:13:15

In a bold economic move, the leader announced a national economic emergency, implementing strategic taxes designed to generate substantial annual revenues. While the new fiscal policy is projected to bring in hundreds of billions of dollars, economists warn of potential ripple effects that could increase prices for American consumers and businesses. The unprecedented economic intervention aims to stabilize the nation's financial landscape, though not without potential challenges to the broader economic ecosystem. The tax initiative represents a significant gamble, balancing the urgent need for revenue generation against the potential risk of economic strain on everyday citizens and commercial enterprises. By declaring a national economic emergency, the administration signals its commitment to addressing fiscal challenges through direct and transformative measures. MORE...

Trade War Redux: Trump's Bold Plan to Supercharge American Manufacturing with Retaliatory Tariffs

Manufacturing

2025-04-02 20:58:31

In a bold move that's set to shake up international trade relations, President Donald Trump is preparing to implement a sweeping series of tariffs targeting both allies and adversaries. These controversial trade measures, which the president characterizes as "reciprocal," promise to dramatically reshape the global economic landscape. The impending tariffs represent a significant escalation in Trump's aggressive trade strategy, signaling his commitment to what he views as fair and balanced international commerce. By applying these economic pressures across the board, the administration aims to level the playing field for American businesses and workers. With this decisive action, Trump continues to challenge traditional trade norms, sending a clear message that the United States is prepared to use its economic leverage to protect domestic interests. The wide-ranging tariffs are expected to spark intense debate and potentially trigger retaliatory measures from affected countries. MORE...

Manufacturing's Quantum Leap: Inside the Industrial Revolution of 2025

Manufacturing

2025-04-02 20:42:04

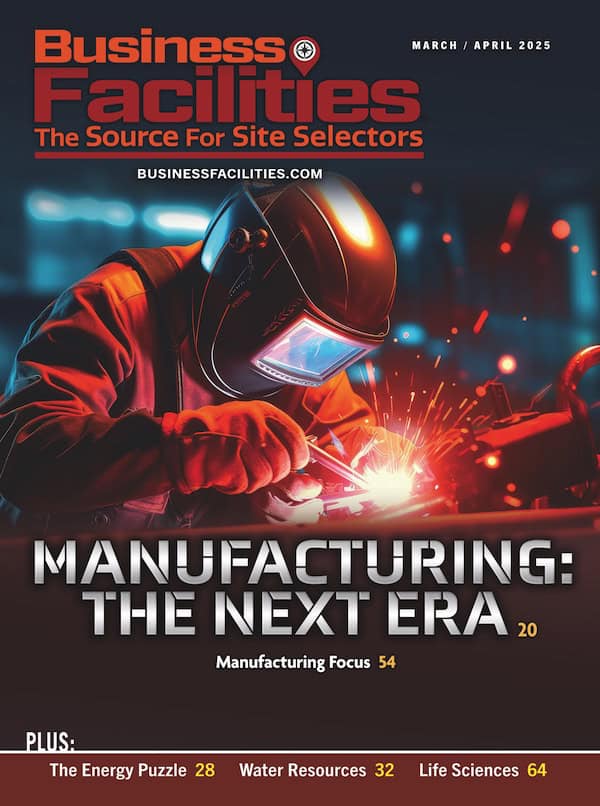

Exploring the Future of Manufacturing: Innovation, Technology, and Sustainability

Our March/April 2025 edition takes a deep dive into the transformative world of manufacturing, showcasing cutting-edge developments that are reshaping industries and driving global progress. This comprehensive issue goes beyond traditional manufacturing perspectives, offering readers an expansive exploration of interconnected sectors including energy, water resources, life sciences, and emerging technological frontiers.

From advanced robotics and artificial intelligence to sustainable production methods and breakthrough scientific innovations, this issue provides an in-depth look at how manufacturing is evolving to meet the complex challenges of the 21st century. We'll examine how interdisciplinary approaches are creating new opportunities for efficiency, sustainability, and technological advancement.

Discover insights into groundbreaking research, industry trends, and the visionary leaders driving manufacturing's next great revolution. Whether you're a professional, researcher, or technology enthusiast, this issue promises to inspire and inform.

MORE...- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238