Cutting-Edge Merger: United Performance Materials Expands Tech Horizons with Fabrisonic Acquisition

Manufacturing

2025-03-19 16:55:58

UPM and Fabrisonic: Revolutionizing Additive Manufacturing Through Strategic Collaboration

In a groundbreaking partnership, UPM and Fabrisonic are set to transform the additive manufacturing landscape, promising innovative solutions that will reshape technological capabilities across multiple industries. This strategic merger combines cutting-edge expertise and advanced manufacturing techniques to deliver unprecedented precision and performance.

By leveraging Fabrisonic's pioneering ultrasonic additive manufacturing technology and UPM's extensive industrial experience, the collaboration aims to push the boundaries of what's possible in 3D printing and advanced material engineering. Their joint approach will enable more complex, lightweight, and high-performance components for sectors ranging from aerospace and automotive to medical and energy.

The merger represents a significant leap forward in additive manufacturing, offering manufacturers unprecedented opportunities to create intricate designs with superior material properties and enhanced structural integrity. Clients can now expect more sophisticated, customized solutions that were previously unimaginable.

As industries continue to demand more innovative and efficient manufacturing processes, this partnership positions UPM and Fabrisonic at the forefront of technological advancement, ready to meet the evolving challenges of modern engineering and design.

MORE...Breaking Barriers: How Smart Process Design is Revolutionizing Cell Therapy Production

Manufacturing

2025-03-19 16:30:00.jpg)

Navigating the Complex Landscape of Advanced Therapy Manufacturing: Insights from an Expert In the rapidly evolving world of cell and gene therapies, successful manufacturing begins long before the first batch is produced. Harvey Branton, a seasoned translational consultant at eXmoor Pharma, offers critical insights into the early process development stages that can make or break an Advanced Therapy Medicinal Product (ATMP). Many developers enter the complex realm of cell and gene therapy with misconceptions that can significantly impact their long-term manufacturing success. Branton emphasizes the importance of strategic planning and understanding the intricate nuances of process development from the very beginning. By challenging common myths and providing expert guidance, Branton helps ATMP developers avoid potential pitfalls that could derail their innovative therapies. His expertise highlights the critical need for a comprehensive, forward-thinking approach to manufacturing that considers scalability, reproducibility, and regulatory compliance. As the cell and gene therapy landscape continues to expand, developers must look beyond initial research and focus on creating robust, adaptable manufacturing processes that can withstand the rigorous demands of bringing groundbreaking therapies from concept to patient. MORE...

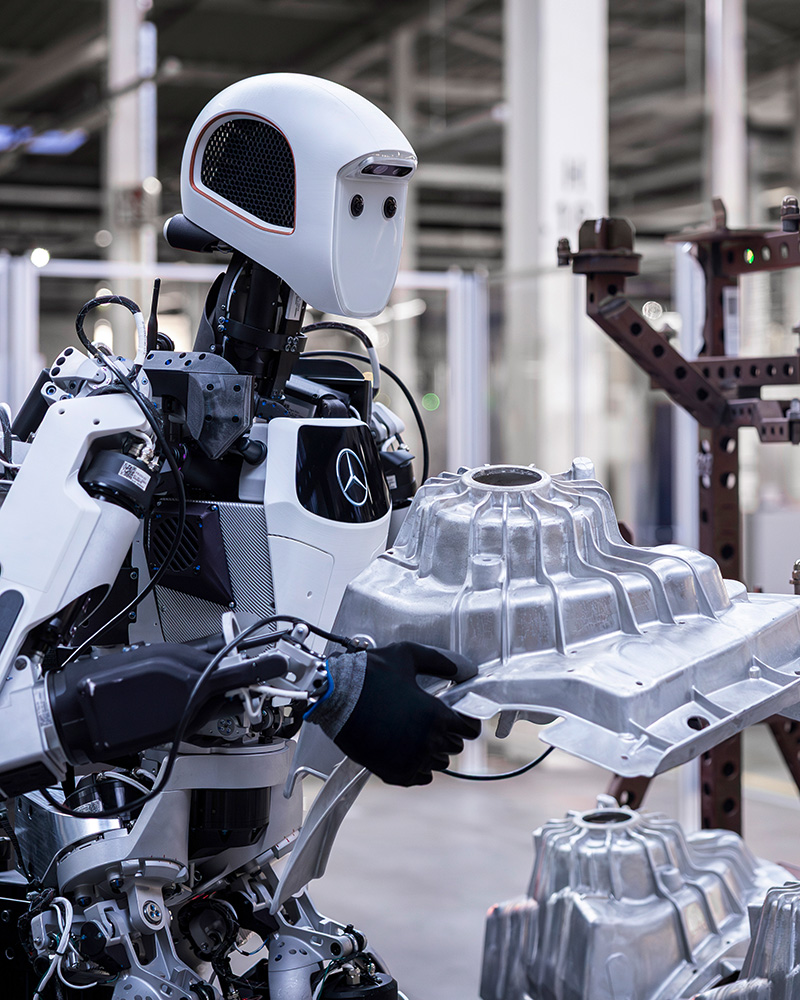

Robots Meet Luxury: Mercedes-Benz Revolutionizes Production with AI and Humanoid Workers

Manufacturing

2025-03-19 15:41:25

Mercedes-Benz is revolutionizing automotive manufacturing by seamlessly blending cutting-edge technology with human expertise at its innovative Digital Factory Campus in Berlin-Marienfelde, Germany. The company has taken a bold step forward by introducing Apollo, a groundbreaking humanoid robot that represents the pinnacle of commercial robotic technology. This strategic integration of artificial intelligence and advanced robotics marks a significant milestone in the company's commitment to enhancing production efficiency and sustainability. Apollo is not just another industrial machine, but a sophisticated technological marvel designed to work alongside human employees, streamlining complex manufacturing processes and pushing the boundaries of what's possible in modern automotive production. By deploying these state-of-the-art humanoid robots, Mercedes-Benz is demonstrating its forward-thinking approach to manufacturing, showcasing how intelligent automation can transform traditional production methods. The Digital Factory Campus serves as a testament to the company's vision of creating a more adaptive, precise, and innovative automotive production ecosystem. As the automotive industry continues to evolve, Mercedes-Benz is positioning itself at the forefront of technological innovation, proving that the future of manufacturing lies in the harmonious collaboration between human creativity and robotic precision. MORE...

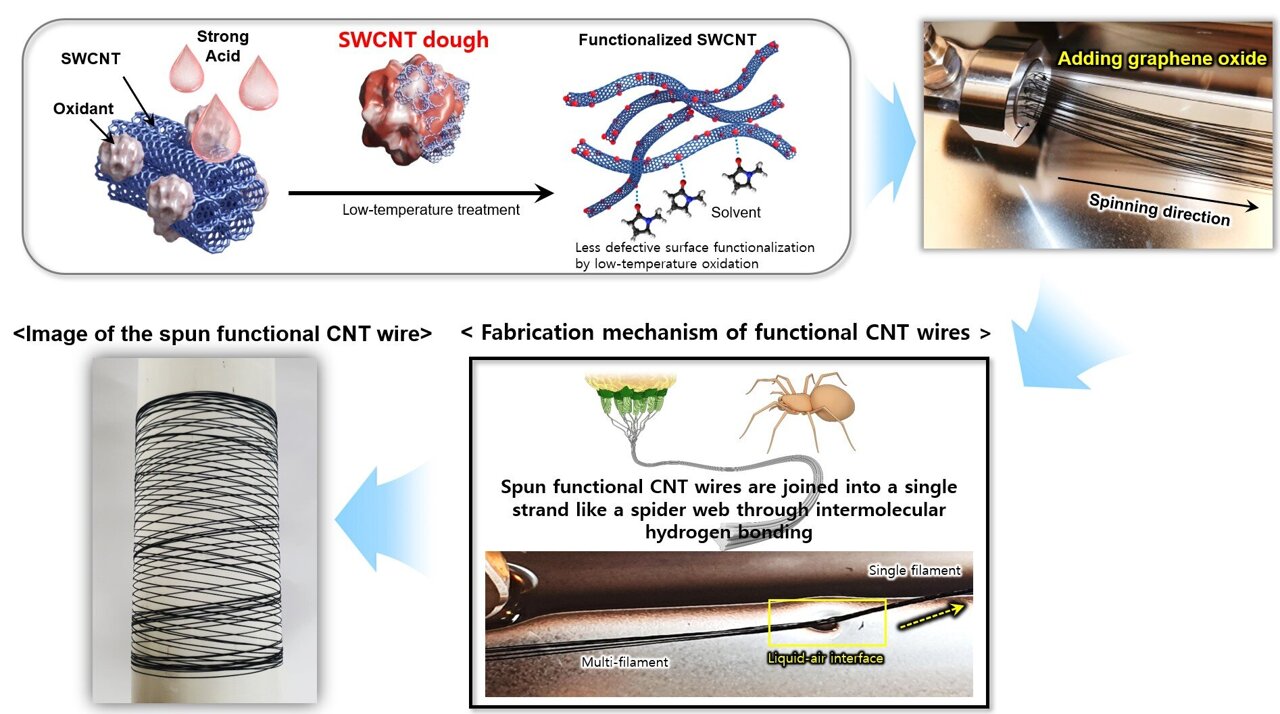

Threads of the Future: How Everyday Fibers Are Becoming High-Tech Wearable Wires

Manufacturing

2025-03-19 15:06:04

In a groundbreaking advancement for wearable technology, Dr. Han Joong Tark and his innovative research team at KERI's Nano Hybrid Technology Research Center have achieved a remarkable breakthrough. The team has successfully developed "functional wires," a critical component that promises to revolutionize the future of wearable electronic devices. These cutting-edge wires represent a significant leap forward in nanotechnology, offering unprecedented potential for creating more flexible, lightweight, and adaptable electronic components. By employing sophisticated direct application techniques, the researchers have engineered a solution that could transform how we interact with technology on a personal level. The development of these functional wires opens up exciting possibilities across multiple fields, including healthcare, fitness tracking, augmented reality, and personal electronics. With their unique properties, these nanoscale wires could enable the creation of more comfortable, seamless, and intelligent wearable devices that integrate smoothly into our daily lives. Dr. Tark's team has demonstrated once again why KERI remains at the forefront of technological innovation, pushing the boundaries of what's possible in nanotechnology and electronic design. MORE...

Green Revolution: SGD Pharma's Bold Leap into Sustainable Pharmaceutical Manufacturing

Manufacturing

2025-03-19 15:00:00

SGD Pharma Pioneers Advanced Glass Manufacturing and Global Pharmaceutical Supply Chain Innovation In a bold move to revolutionize pharmaceutical packaging and supply chain resilience, SGD Pharma is making significant strategic investments in cutting-edge glass manufacturing technologies. The company is positioning itself at the forefront of pharmaceutical packaging innovation, demonstrating a commitment to enhancing production capabilities in the United States and expanding its global reach. By leveraging next-generation manufacturing techniques, SGD Pharma is not just upgrading its production infrastructure but also addressing critical challenges in pharmaceutical supply chains. The company's forward-thinking approach aims to provide pharmaceutical manufacturers with high-quality, precision-engineered glass containers that meet the increasingly complex demands of modern medical treatments. These investments signal SGD Pharma's dedication to supporting the pharmaceutical industry's evolving needs, ensuring reliable, safe, and efficient packaging solutions. By focusing on advanced manufacturing processes, the company is set to strengthen its competitive position and contribute to the robustness of global pharmaceutical supply networks. As the industry continues to face unprecedented challenges, SGD Pharma's strategic investments represent a proactive approach to innovation, quality, and supply chain reliability. MORE...

Sweet Innovation: Blommer Chocolate Unveils Cutting-Edge Research Hub

Manufacturing

2025-03-19 14:54:22

In a remarkable turn of events, the company has announced a groundbreaking reopening just twelve months after the closure of its iconic Chicago manufacturing facility. This strategic revival marks a significant milestone for the organization, signaling renewed hope and commitment to the local manufacturing landscape. The plant's resurrection comes as a testament to the company's resilience and forward-thinking approach, breathing new life into a facility that many had written off just a year ago. By recommitting to this historic location, the company demonstrates its dedication to American manufacturing and the skilled workforce that has long been the backbone of its success. This reopening not only represents a financial investment but also a powerful statement of confidence in the region's economic potential. Local workers and community leaders are celebrating the return of jobs and economic opportunity, viewing the plant's revival as a beacon of hope in an challenging industrial environment. MORE...

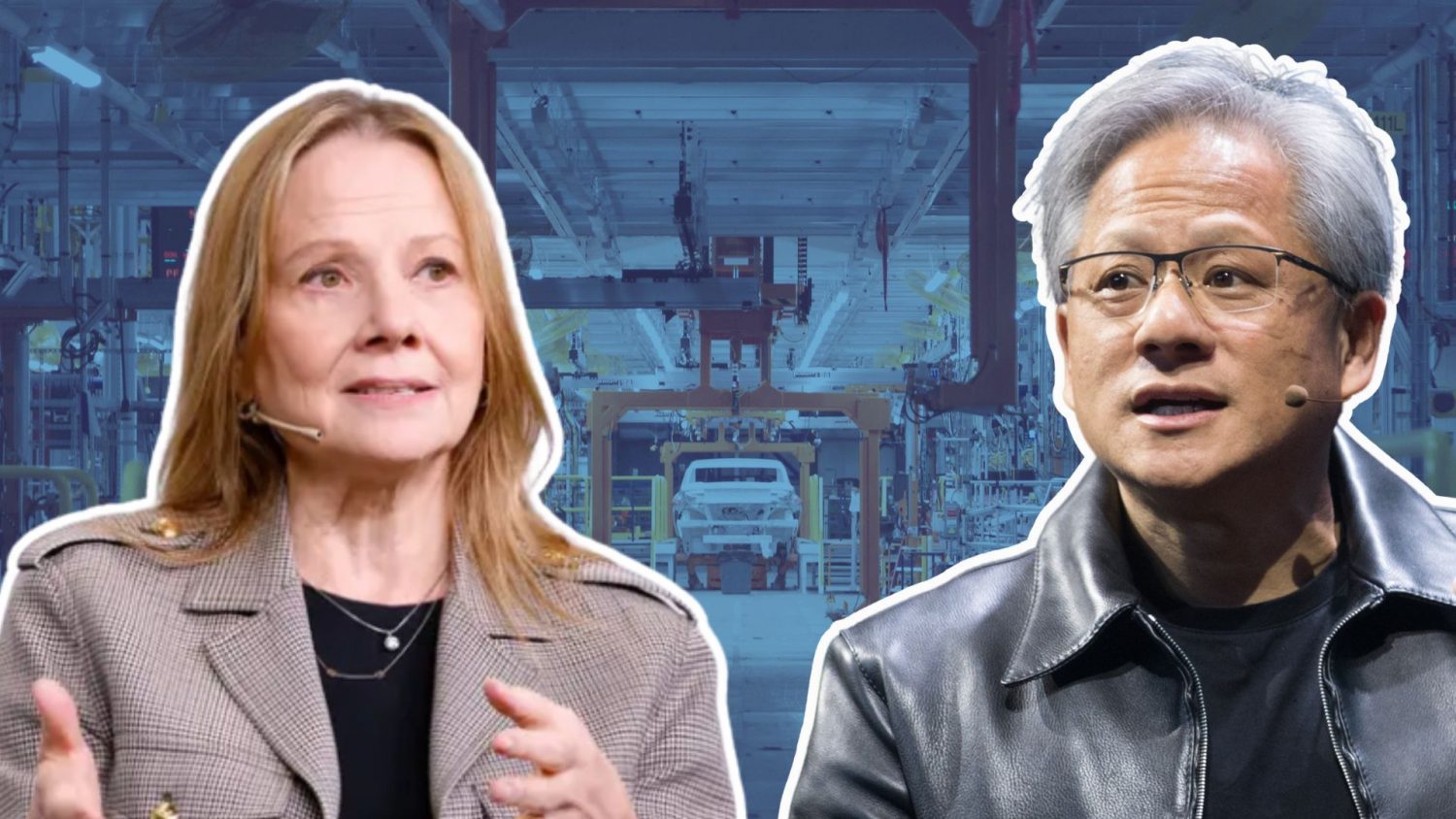

Driving the Future: GM and Nvidia Forge Groundbreaking AI Partnership

Manufacturing

2025-03-19 14:34:50

General Motors (GM) and Nvidia are taking their technological partnership to new heights, forging a groundbreaking collaboration that promises to revolutionize the automotive industry through advanced artificial intelligence integration. The two tech powerhouses are set to embed cutting-edge AI technologies across GM's entire ecosystem, spanning next-generation vehicles, sophisticated driver-assistance systems, and intelligent manufacturing facilities. This expanded partnership represents a strategic leap forward in automotive innovation, with Nvidia's powerful AI computing platforms set to transform how GM designs, manufactures, and operates its vehicles. By leveraging state-of-the-art AI technologies, the companies aim to enhance vehicle performance, safety, and user experience in unprecedented ways. The collaboration will focus on implementing AI across multiple critical areas, including autonomous driving capabilities, predictive maintenance systems, personalized in-vehicle experiences, and smart manufacturing processes. Nvidia's advanced AI computing solutions will provide the computational backbone needed to support GM's ambitious technological vision. As the automotive industry continues to evolve rapidly, this partnership positions GM at the forefront of technological innovation, demonstrating a commitment to integrating artificial intelligence into every aspect of vehicle development and operation. The synergy between GM's automotive expertise and Nvidia's cutting-edge AI technologies promises to reshape the future of transportation. MORE...

Velo3D Accelerates Manufacturing: Breakthrough Rapid Production Solutions Unveiled

Manufacturing

2025-03-19 13:18:19

Revolutionizing Supply Chains: Velo3D's Cutting-Edge Rapid Production Solutions

In today's dynamic global marketplace, businesses are constantly seeking innovative strategies to build resilient and adaptable supply chains. Velo3D emerges as a game-changing technology partner, offering advanced manufacturing solutions that transform traditional production paradigms.

The Power of Advanced Manufacturing Technology

Velo3D's rapid production solutions represent a quantum leap in manufacturing capabilities. By leveraging state-of-the-art 3D printing technologies, companies can now:

- Dramatically reduce production lead times

- Minimize inventory holding costs

- Create complex geometries previously impossible with conventional manufacturing

- Enhance supply chain flexibility and responsiveness

Breaking Traditional Manufacturing Limitations

Traditional manufacturing methods often impose significant constraints on design and production. Velo3D's innovative approach eliminates these barriers, enabling businesses to:

- Produce intricate components with unprecedented precision

- Optimize material usage and reduce waste

- Accelerate product development cycles

- Implement on-demand manufacturing strategies

Building Resilience Through Technology

In an era of global uncertainty, Velo3D's rapid production solutions provide companies with a strategic advantage. By decentralizing production and enabling rapid prototyping and manufacturing, businesses can:

- Mitigate supply chain disruptions

- Reduce dependency on traditional manufacturing networks

- Quickly adapt to changing market demands

- Maintain competitive edge through technological innovation

Embrace the future of manufacturing with Velo3D's revolutionary rapid production solutions – where innovation meets resilience.

MORE...Battery Boom: LG Energy Solution Vertech Doubles Down on US Manufacturing Ambitions

Manufacturing

2025-03-19 13:03:28

In the rapidly evolving landscape of energy storage, LG ES Vertech is pioneering a transformative approach to electric vehicle (EV) battery repurposing. During an exclusive interview with ESN Premium, Jaehong Park, the company's visionary CEO, shed light on the innovative strategies driving the adaptation of EV battery lines for stationary storage applications. Park emphasized the critical importance of sustainable battery lifecycle management, highlighting how retired EV batteries can find a second life in grid-scale energy storage solutions. "Our goal is to maximize the value and potential of these batteries beyond their automotive applications," he explained, underscoring the company's commitment to circular economy principles. The technological challenges of repurposing EV batteries are significant, but LG ES Vertech is developing sophisticated diagnostic and reconfiguration techniques. By carefully assessing battery health, performance characteristics, and remaining capacity, the company can effectively transform these batteries into reliable stationary storage systems. This approach not only reduces electronic waste but also provides a cost-effective solution for expanding renewable energy infrastructure. As the demand for energy storage continues to grow, Park believes that battery repurposing will play a crucial role in supporting the global transition to sustainable energy technologies. With innovative strategies and a forward-thinking approach, LG ES Vertech is positioning itself at the forefront of the energy storage revolution, demonstrating how intelligent battery lifecycle management can drive both environmental sustainability and economic efficiency. MORE...

Inside Unilever's Chicago Powerhouse: Where Innovation Meets Manufacturing Grit

Manufacturing

2025-03-19 12:32:31

In a groundbreaking recognition of workplace innovation, the World Economic Forum and McKinsey & Co have spotlighted this exceptional factory as a trailblazer in their prestigious Frontline Talent of the Future Initiative. This remarkable acknowledgment underscores the factory's visionary approach to workforce development and cutting-edge talent management strategies that are reshaping the future of industrial employment. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238