Electric Vehicle Empire Unravels: Rare Tech Auction Reveals Manufacturing Secrets

Manufacturing

2025-03-27 16:49:17

Electric Vehicle Industry Auction: Rare Opportunity for Investors and Enthusiasts Maynards Group, a leading auction, appraisal, and financing service provider, is set to host an intriguing online auction featuring assets from a recently defunct electric vehicle manufacturer. While the company remains tight-lipped about the specific identity, sharp-eyed observers might draw connections to a certain superhero team known for their cutting-edge technology. The highly anticipated auction is scheduled for April 10th at 10:00 am Pacific Time, promising a unique chance for potential buyers to acquire valuable assets from an innovative but ultimately unsuccessful EV venture. Interested parties can participate online, offering a convenient and accessible way to explore this rare opportunity. Investors, automotive enthusiasts, and technology collectors will want to mark their calendars for this exclusive event. The auction represents a potential treasure trove of equipment, intellectual property, and specialized machinery from the automotive industry's rapidly evolving electric vehicle sector. Stay tuned for more details about this exciting auction that could reshape someone's automotive or technological aspirations. MORE...

Forging Futures: How Northeast Indiana is Transforming Student Pathways into Manufacturing Powerhouses

Manufacturing

2025-03-27 16:41:25

Empowering Future Manufacturers: Whitko Career Academy Launches Innovative Workforce Development Program The ManufacturED program is set to revolutionize career training for local students, offering an unprecedented opportunity for aspiring manufacturing professionals. Students at the Whitko Career Academy in Larwill will now have direct access to cutting-edge industry experience through strategic partnerships with local manufacturing companies. This groundbreaking initiative provides students with a comprehensive pathway to success, combining classroom learning with real-world skill development. Participants will gain essential manufacturing skills, engage in hands-on work experiences, and secure valuable internships that can launch their careers in the thriving manufacturing sector. By bridging the gap between education and industry, the ManufacturED program aims to create a robust pipeline of skilled workers prepared to meet the dynamic demands of modern manufacturing. Students will not just learn theoretical concepts, but will actively develop practical expertise that makes them immediately valuable to local employers. MORE...

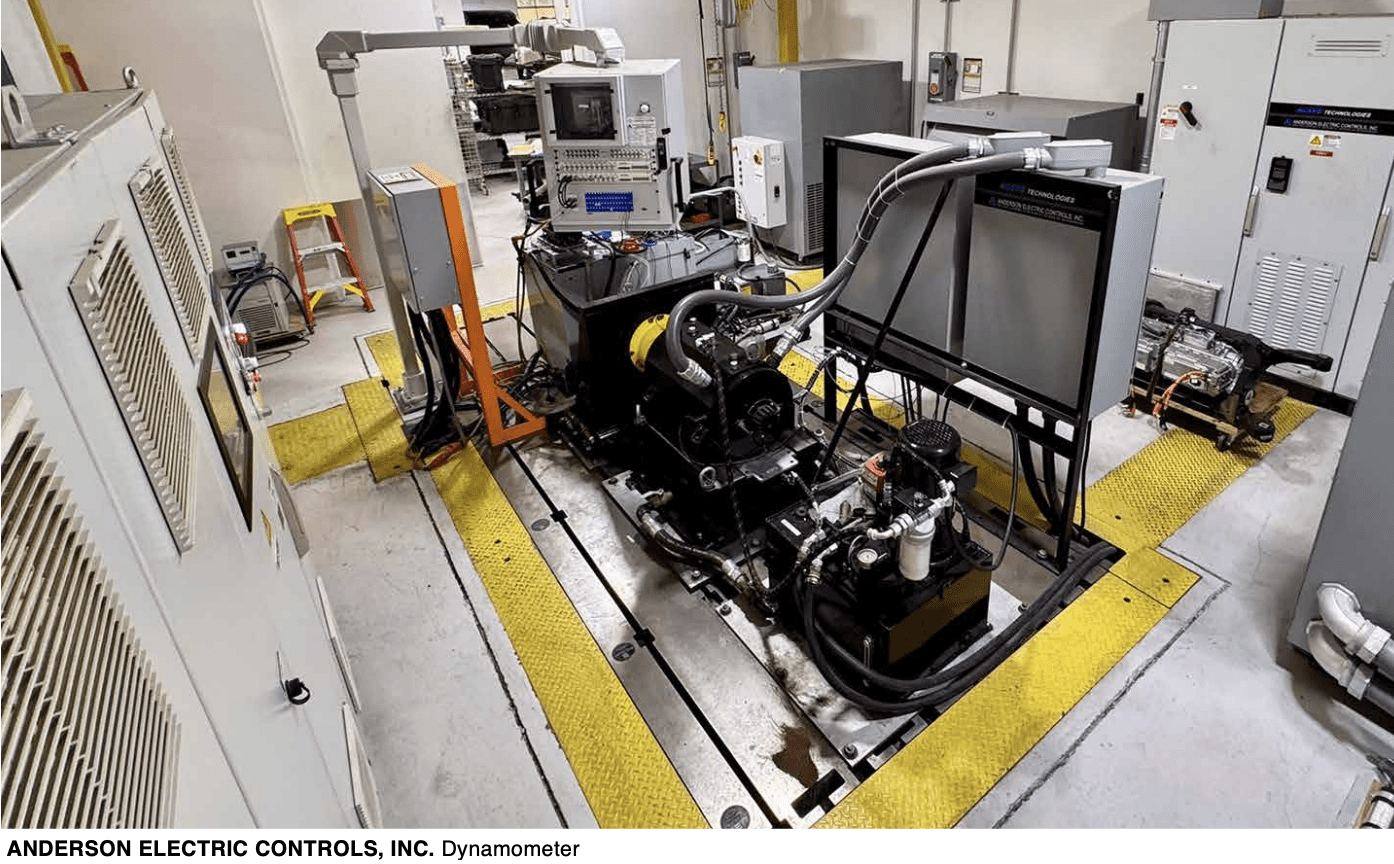

Data Center Boom: How Manufacturing Is Powering the Digital Energy Crisis

Manufacturing

2025-03-27 16:27:16

Natural gas plays a crucial role in maintaining affordable electricity prices, according to industry expert Guith. As energy markets continue to evolve, the versatility and cost-effectiveness of natural gas have emerged as key factors in keeping power generation expenses in check for consumers. Guith emphasized that natural gas provides a reliable and flexible energy source that helps stabilize electricity costs. Its ability to quickly ramp up or down in response to changing energy demands makes it an invaluable component of the modern power grid. This adaptability not only ensures consistent electricity supply but also helps prevent dramatic price fluctuations that can burden households and businesses. The expert highlighted how natural gas has become a critical bridge in the transition to cleaner energy sources, offering a more environmentally friendly alternative to coal while maintaining economic accessibility. Its lower carbon emissions and competitive pricing make it an attractive option for both energy providers and consumers seeking affordable and responsible power solutions. MORE...

Manufacturing Mirage: Trump's Industrial Policy Threatens U.S. Economic Resilience

Manufacturing

2025-03-27 16:00:00

President Trump's bold vision of reviving American manufacturing may ultimately prove counterproductive, potentially creating a cascade of unintended consequences that could undermine the very economic renaissance he envisions. The ambitious plan to reinvigorate domestic manufacturing is fraught with significant challenges. Consumers are likely to bear the brunt of increased production costs, as protectionist policies and reshoring efforts could drive up prices for goods across multiple sectors. Moreover, the environmental implications of rapid industrial expansion could be substantial, potentially offsetting any economic gains with increased carbon emissions and resource consumption. Perhaps most critically, the manufacturing sector faces a profound skills gap. The complex, technology-driven nature of modern manufacturing demands specialized expertise that cannot be quickly or easily replaced. As traditional manufacturing jobs have declined over decades, the workforce has shifted, leaving a critical shortage of skilled workers needed to support a large-scale industrial revival. While the intention to strengthen American manufacturing is commendable, the practical implementation may reveal a stark disconnect between political rhetoric and economic reality. The path to a true manufacturing renaissance requires more nuanced strategies that address workforce development, technological innovation, and sustainable economic growth. MORE...

Breaking: Manufacturing Workforce Unveils Groundbreaking National Economic Snapshot

Manufacturing

2025-03-27 14:58:00

The Manufacturing Imperative Workforce Pipeline Challenge (MI-WPC) is making significant strides in addressing the critical skills gap in manufacturing education. By strategically partnering with 25 community colleges across 17 states, the initiative is building a robust pathway to transform workforce development. With an ambitious vision, MI-WPC aims to create a transformative learning ecosystem that will engage and inspire 1,000 learners at each participating college annually. Over the next three years, the program is targeting a remarkable milestone of reaching 75,000 potential manufacturing professionals, effectively bridging the talent pipeline between education and industry. This collaborative approach demonstrates a powerful commitment to revitalizing the manufacturing sector by investing in comprehensive education and training programs that prepare the next generation of skilled workers for high-demand careers. MORE...

Pharma Giant Chiesi Pumps €430M into Italian Manufacturing Powerhouse

Manufacturing

2025-03-27 14:47:27

A once-dormant manufacturing hub in Milan is experiencing a remarkable transformation, breathing new life into its industrial legacy through a groundbreaking investment by Italian pharmaceutical giant Chiesi. The company has unveiled an ambitious 430 million euro (approximately $464 million) plan to revitalize a historic production site in the Nerviano municipality, signaling a significant commitment to innovation and local industrial renewal. As part of its global expansion strategy, Chiesi is set to construct a state-of-the-art facility dedicated to producing advanced inhalers and cutting-edge health products. This substantial investment not only promises to modernize the existing manufacturing infrastructure but also represents a powerful vote of confidence in the region's industrial potential. The project will strategically repurpose a long-shuttered manufacturing site, transforming what was once a dormant industrial space into a dynamic center of pharmaceutical innovation. By breathing new life into this historic location, Chiesi is demonstrating its commitment to sustainable development and local economic revitalization. This bold initiative underscores the company's forward-thinking approach, blending respect for industrial heritage with a vision for future medical technology and manufacturing excellence. MORE...

Wheels of Collaboration: How Canada and Mexico Shaped America's Auto Industry

Manufacturing

2025-03-27 14:33:13

From the dawn of automotive manufacturing in North America, international labor has been the lifeblood of American car production. For generations, automakers have strategically tapped into the skilled workforce of neighboring countries, drawing talent and expertise from Canada and Mexico to fuel the engine of industrial innovation. These cross-border labor partnerships have been more than just a workforce solution—they've been a testament to the interconnected nature of North American manufacturing. Canadian and Mexican workers have played a crucial role in building, designing, and sustaining the automotive industry, bringing unique skills, perspectives, and work ethic to assembly lines and design studios across the continent. The symbiotic relationship between American automakers and their international workforce has not only driven economic growth but has also created a rich tapestry of collaborative manufacturing that transcends national boundaries. From the bustling factories of Detroit to the advanced production facilities in border regions, this international labor dynamic continues to be a cornerstone of automotive production in North America. MORE...

Synergy Unleashed: How Industry 5.0 is Redefining Human-Machine Collaboration

Manufacturing

2025-03-27 14:00:00

Bridging Technology and Human Creativity: The Path to Industry 5.0 In the evolving landscape of advanced manufacturing, the convergence of smart technologies and human innovation is reshaping the industrial paradigm. Manufacturing Execution Systems (MES) are at the forefront of this transformation, seamlessly blending cutting-edge digital solutions with the irreplaceable power of human ingenuity. Industry 5.0 represents more than just technological advancement; it's a collaborative ecosystem where intelligent systems and human expertise work in harmony. By integrating sophisticated MES platforms, manufacturers can unlock unprecedented levels of efficiency, flexibility, and creativity. These smart technologies don't replace human workers but empower them to make more strategic, informed decisions. The magic happens when advanced algorithms and intuitive interfaces meet the nuanced problem-solving skills of skilled professionals. MES technologies provide real-time insights, predictive analytics, and streamlined workflows, while human workers bring critical thinking, adaptability, and innovative solutions that no machine can replicate. As we move towards this new industrial frontier, the synergy between smart manufacturing technologies and human talent will be the key to driving unprecedented productivity, sustainability, and competitive advantage in the global marketplace. MORE...

Kimberly-Clark Breaks Ground: First Tissue Plant Signals Major Manufacturing Expansion

Manufacturing

2025-03-27 12:59:47

In a significant milestone for sustainable manufacturing, Kimberly-Clark (K-C), a global leader in personal care and hygiene products, has unveiled an innovative transformation at its Koblenz, Germany facility. The manufacturing site has achieved a groundbreaking status as the company's first tissue production plant worldwide with a clear strategic pathway toward operational transition. This landmark development signals Kimberly-Clark's commitment to environmental sustainability and cutting-edge manufacturing practices. By establishing a comprehensive roadmap for transitioning its operations, the Koblenz site represents a pivotal moment in the company's global sustainability strategy. The move underscores Kimberly-Clark's proactive approach to reducing environmental impact and embracing more sustainable production methods in the personal care industry. As a pioneering step, this facility will serve as a potential model for future site transformations across the company's international manufacturing network. MORE...

Behind the Slowdown: India's Manufacturing Maze Unraveled

Manufacturing

2025-03-27 12:50:00

India's Ambitious Manufacturing Dream: A Work in Progress India has long harbored aspirations of transforming into a global manufacturing powerhouse, positioning itself as a formidable alternative to traditional manufacturing giants like China. Five years ago, the government launched a bold, flagship initiative designed to accelerate this transformative journey. However, despite the grand vision and significant investment, the program has struggled to meet its ambitious targets. The scheme, intended to revolutionize India's industrial landscape, has encountered numerous challenges that have hindered its full potential. Complex bureaucratic processes, infrastructure limitations, and competitive global market dynamics have collectively contributed to the program's mixed results. While the intent was clear—to boost domestic manufacturing, create jobs, and reduce reliance on imports—the execution has been more nuanced and complex than initially anticipated. Despite these setbacks, the Indian government remains committed to its manufacturing vision. Policymakers continue to refine strategies, introduce incentives, and create more conducive environments for industrial growth. The journey toward becoming a manufacturing powerhouse is ongoing, with each challenge presenting an opportunity for learning and adaptation. As India navigates this intricate path, the world watches with keen interest, recognizing the potential of a nation poised at the cusp of an industrial transformation. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238