Manufacturing's Digital Revolution: $1.17 Trillion Market Set to Explode by 2032

Manufacturing

2025-04-11 14:30:00

Digital Transformation Market in Manufacturing Set to Reach $1.17 Trillion by 2032

A groundbreaking market research report by Meticulous Research® reveals an extraordinary trajectory for the global digital transformation market in the manufacturing sector. The industry is poised to experience remarkable growth, with projections indicating a substantial market value of $1,170.7 billion by 2032.

Key Market Insights

- Projected Market Value: $1,170.7 billion by 2032

- Compound Annual Growth Rate (CAGR): 23.7% from 2025 to 2032

- Primary Drivers: Technological advancements and digital innovation

Market Scope and Components

The comprehensive report examines various critical aspects of digital transformation, including:

- Offerings: Services

- Enterprise Size: Diverse range of organizations

- Deployment Modes: Multiple implementation strategies

- Key Technologies:

- Cloud Computing

- Artificial Intelligence & Machine Learning

- Internet of Things (IoT)

- Augmented & Virtual Reality

- End-use Industry Focus: Pharmaceuticals

This robust growth underscores the manufacturing sector's increasing commitment to digital transformation, leveraging cutting-edge technologies to enhance operational efficiency, productivity, and competitive advantage.

MORE...Kyowa Kirin Unveils $118M Biologics Facility, Signals Global Expansion Amid US Project Progress

Manufacturing

2025-04-11 14:00:52.jpg)

Kyowa Kirin Expands Global Manufacturing Capabilities with Dual Biologics Facilities Specialty pharmaceutical company Kyowa Kirin is making significant strides in its manufacturing infrastructure, simultaneously advancing construction of a new biologics plant in North Carolina while completing a companion facility in Japan. The company's latest investment is a state-of-the-art $118 million manufacturing complex located in Takasaki, Japan, strategically designed to support early-stage drug development. This new facility will specialize in producing investigational drugs, with a particular focus on advanced antibody research and development. By establishing these complementary manufacturing sites in both the United States and Japan, Kyowa Kirin is positioning itself to accelerate innovative biologics research and enhance its global pharmaceutical production capabilities. The Takasaki plant represents a critical expansion of the company's research and development infrastructure, enabling more efficient and flexible drug development processes. As the pharmaceutical industry continues to evolve, Kyowa Kirin's strategic investments demonstrate its commitment to cutting-edge medical research and advanced manufacturing technologies. MORE...

Manufacturing Renaissance: Can America Reclaim Its Industrial Crown?

Manufacturing

2025-04-11 12:30:24

In a bold move to revitalize American manufacturing, President Trump ushered in a new era of trade policy by imposing the most significant tariff increases seen in nearly a century. Harking back to the protectionist strategies of the 1930s, these sweeping tariffs were designed to shield domestic industries and encourage production within U.S. borders. The administration's aggressive trade approach aimed to level the global economic playing field, challenging long-standing international trade dynamics. By implementing substantial tariffs, Trump sought to create a more favorable environment for American manufacturers, hoping to bring jobs back to the United States and reduce reliance on foreign imports. These unprecedented trade measures marked a dramatic shift in economic policy, signaling a commitment to prioritizing domestic industrial strength and economic self-sufficiency. The tariffs represented more than just a financial strategy – they were a statement of intent to reshape America's economic landscape and restore the country's manufacturing prowess. MORE...

Chip War Tactics: China Reshapes Semiconductor Rules to Empower Domestic Tech Giants

Manufacturing

2025-04-11 12:00:04

In a significant shift for the global semiconductor landscape, the China Semiconductor Industry Association has unveiled a crucial insight into chip manufacturing. According to their latest statement, the true origin of semiconductor chips is now definitively tied to the geographical location of wafer fabrication plants. This revelation highlights the increasingly complex and geographically nuanced nature of modern chip production. No longer can a chip's provenance be simply determined by traditional design or corporate headquarters, but instead by the precise physical location where the intricate wafer manufacturing process takes place. The association's declaration underscores the growing importance of manufacturing infrastructure in the semiconductor industry, emphasizing how geographical factors play a critical role in defining a chip's true point of origin. As global technology supply chains become more interconnected, this perspective offers a fresh understanding of semiconductor production and national technological capabilities. MORE...

Pharma Giant Novartis Unveils Massive $23 Billion Investment to Supercharge US Innovation and Production

Manufacturing

2025-04-11 11:02:57

Novartis is making a bold strategic move to revolutionize its pharmaceutical manufacturing landscape in the United States. The global healthcare giant has unveiled an ambitious plan to invest substantially in cutting-edge manufacturing and research facilities, with a groundbreaking commitment to produce 100% of its critical medicines domestically. This significant investment signals a major shift in Novartis's production strategy, aiming to strengthen its domestic manufacturing capabilities and reduce reliance on international supply chains. By localizing production, the company not only enhances its operational resilience but also demonstrates a strong commitment to supporting the US pharmaceutical ecosystem. The comprehensive investment will encompass state-of-the-art research and development centers, alongside advanced manufacturing infrastructure. This strategic initiative is expected to create numerous high-skilled jobs, drive innovation, and potentially reshape the pharmaceutical manufacturing landscape in the United States. Novartis's bold commitment reflects a growing trend of pharmaceutical companies seeking to build more robust and localized production networks, particularly in the wake of global supply chain disruptions experienced in recent years. MORE...

Chip Escape Plan: How US Tech Giants Are Dodging China's Trade War Tariffs

Manufacturing

2025-04-11 10:17:39

In a surprising move, U.S. chipmakers that outsource their manufacturing will receive a reprieve from China's retaliatory tariffs on American imports. The state-backed China Semiconductor Industry Association (CSIA) released an urgent notice on Friday that provides a significant loophole for semiconductor companies. The key revelation lies in the customs classification: "For all integrated circuits, whether packaged or unpackaged, the declared country of origin for import customs purchases is the location of the wafer fabrication plant," according to the CSIA. This means that chip designers like Qualcomm and AMD, who rely on Taiwan Semiconductor Manufacturing Company (TSMC) for production, will have their products classified under Taiwan's origin. This nuanced approach suggests a strategic softening of China's trade stance, potentially offering a lifeline to U.S. semiconductor companies that have been navigating complex international trade tensions. The decision could provide some economic relief and flexibility for American tech firms operating in the global semiconductor supply chain. The announcement by the CSIA, which represents China's largest chip companies, signals a potentially more pragmatic approach to trade restrictions, acknowledging the intricate global nature of semiconductor manufacturing and design. MORE...

Manufacturing Meltdown: Trump's Policy Shift Leaves Workers in the Lurch

Manufacturing

2025-04-11 10:00:00

In a striking display of contradictory policy-making, the Trump Administration revealed its true colors just hours before announcing tariffs ostensibly designed to bolster American manufacturing. Behind the scenes, the administration strategically dismantled a critical program that has been instrumental in generating billions of dollars in revenue for U.S. manufacturers. The move exposes a glaring disconnect between the administration's public rhetoric and its actual support for domestic industrial growth. While trumpeting protectionist trade measures with one hand, officials were simultaneously undermining a key economic support mechanism that has been vital to manufacturers' success. This calculated undermining of manufacturing support programs raises serious questions about the administration's genuine commitment to American industrial competitiveness. The quiet gutting of this program suggests a more complex and potentially harmful approach to economic policy than the administration's public statements would indicate. The timing of this action—just before a high-profile tariff announcement—only serves to highlight the apparent inconsistency and potential cynicism underlying the administration's economic strategy. MORE...

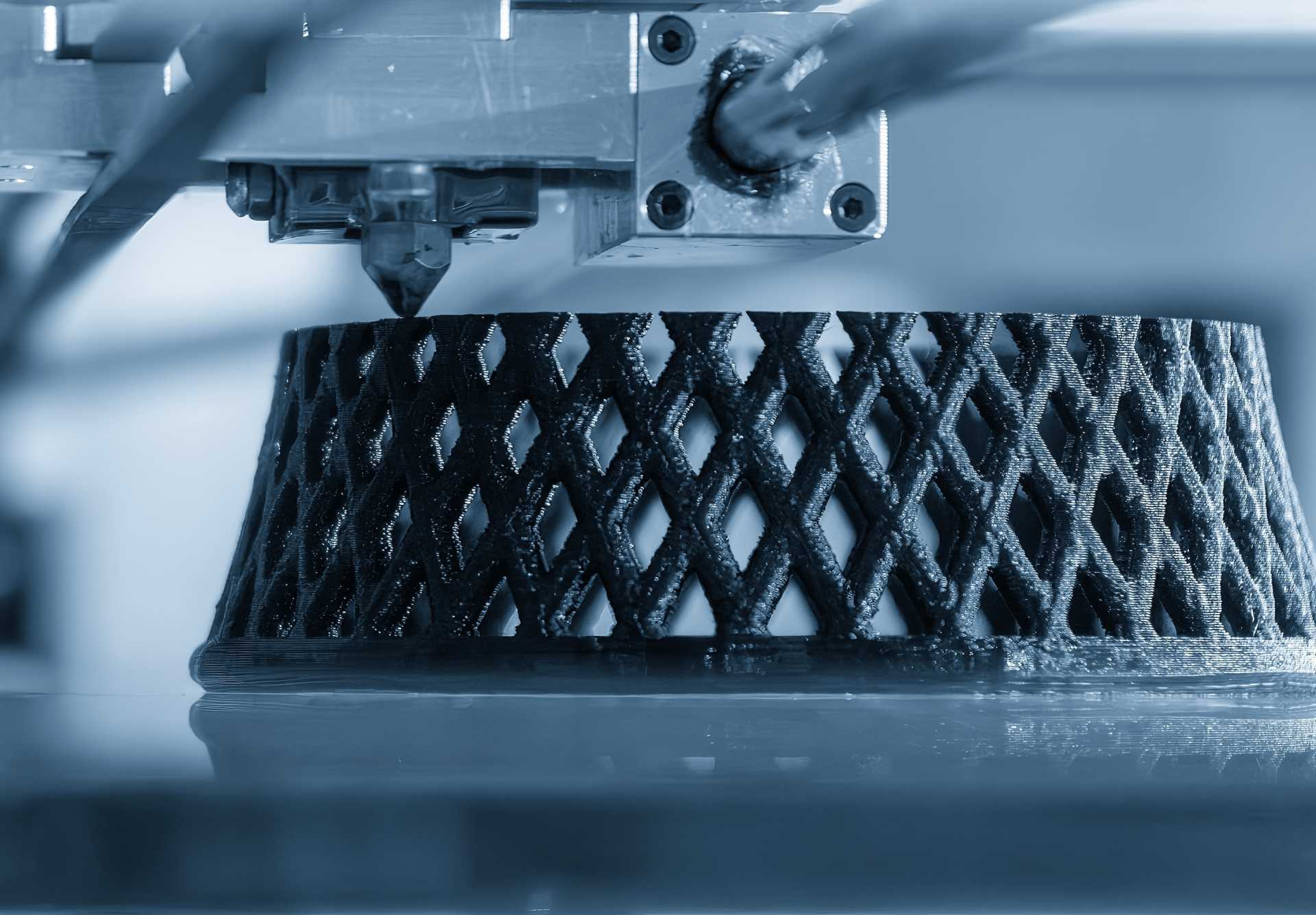

Breaking Boundaries: How Two Innovators Are Revolutionizing Additive Manufacturing Testing

Manufacturing

2025-04-11 10:00:00

In the rapidly evolving world of additive manufacturing, precision and quality are paramount. Recently, industry experts Jerry Capo and Dr. Alex Kinsey sat down with Editor Lawrence Moebs to shed light on why rigorous testing has become more critical than ever in 3D printing technologies. The conversation delved deep into the complexities of modern manufacturing, highlighting how advanced testing protocols can make the difference between breakthrough innovation and potential failure. Capo and Kinsey emphasized that as additive manufacturing continues to push technological boundaries, comprehensive testing is no longer just a recommended step—it's an absolute necessity. Dr. Kinsey pointed out that the intricate nature of 3D printing processes demands meticulous examination at every stage. From material selection to final product verification, each step requires careful scrutiny to ensure structural integrity, performance, and reliability. Jerry Capo added that emerging technologies are creating unprecedented challenges and opportunities in testing methodologies. "We're not just checking boxes," he explained, "we're developing sophisticated approaches that can predict and prevent potential manufacturing defects before they become costly problems." Their insights underscore a crucial message: in additive manufacturing, testing isn't just about quality control—it's about pushing the boundaries of what's possible while maintaining the highest standards of precision and innovation. MORE...

From Precision to Progress: Bentley's Quarter-Century Revolution in 3D Manufacturing

Manufacturing

2025-04-11 08:47:10

Bentley Motors Celebrates a Quarter-Century of Cutting-Edge 3D Printing Innovation In a remarkable milestone, Bentley Motors is commemorating 25 years of groundbreaking Additive Manufacturing (AM) technology at its prestigious headquarters in Crewe. What began as an experimental technology has now become a cornerstone of the luxury automotive manufacturer's design and production processes. Over the past two and a half decades, 3D printing has revolutionized the way Bentley approaches prototype development, custom part creation, and intricate design solutions. The technology has enabled the brand to push the boundaries of automotive engineering, allowing for unprecedented levels of precision, creativity, and efficiency. From rapid prototyping to creating complex components that would be impossible to manufacture through traditional methods, Bentley's commitment to additive manufacturing has been a key driver of its innovative spirit. The company has transformed 3D printing from a novel concept to an integral part of its manufacturing ecosystem, demonstrating how advanced technologies can reshape the future of luxury automotive design. As Bentley reflects on 25 years of this transformative technology, it stands as a testament to the brand's forward-thinking approach and continuous pursuit of engineering excellence. MORE...

LEGO's Strategic Expansion: Brick Giant Breaks Ground in Vietnam's Manufacturing Landscape

Manufacturing

2025-04-11 08:00:59

LEGO Expands Asian Presence with Cutting-Edge Sustainable Factory in Vietnam In a strategic move that underscores its commitment to regional growth and environmental responsibility, LEGO has inaugurated a state-of-the-art manufacturing facility in Vietnam. This innovative factory represents a significant milestone in the company's expansion strategy, designed to enhance manufacturing agility and serve the growing demand for LEGO products across the Asian market. The new facility goes beyond traditional manufacturing approaches, embedding sustainability at its core. By establishing a production hub closer to its target market, LEGO aims to reduce transportation emissions and create more localized, efficient manufacturing processes. This approach not only supports the company's environmental goals but also enables faster product delivery to children throughout Asia. With a focus on regional needs and sustainable practices, the Vietnam factory symbolizes LEGO's forward-thinking approach to global manufacturing. By investing in local infrastructure and prioritizing eco-friendly production methods, the company continues to demonstrate its dedication to both play and planetary well-being, ensuring that more children can experience the joy of LEGO's creative building experiences. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238