Silicon Valley Startup ChEmpower Bags Nearly $20M to Revolutionize Chip Manufacturing Tech

Manufacturing

2025-04-24 13:00:00

ChEmpower Secures $18.7M to Revolutionize Semiconductor Manufacturing

In a significant boost for advanced chip technology, ChEmpower, a pioneering semiconductor materials company, has successfully closed a Series A funding round, raising $18.7 million. The strategic investment will accelerate the company's innovative polish pads and chemical solutions for semiconductor planarization.

Leading the funding round are M Ventures and Rhapsody Venture Partners, with strong participation from a prestigious group of technology investors. Notable contributors include Intel Capital, Pangaea Ventures, Foothill Ventures, In-Q-Tel (IQT), and TEL Venture Capital, demonstrating robust confidence in ChEmpower's technological potential.

The fresh capital will be instrumental in scaling ChEmpower's cutting-edge technologies, positioning the company to make substantial advancements in chip manufacturing and packaging processes. This funding marks a critical milestone in the company's mission to drive innovation in semiconductor materials.

MORE...Dogecoin Severs Ties with Signal Mountain Firm in Surprising Manufacturing Shakeup

Manufacturing

2025-04-24 01:02:00

In a puzzling twist of policy, President Donald Trump's administration appears to be sending mixed signals about domestic manufacturing. While publicly championing tariffs as a means to revitalize American industrial production, the White House is simultaneously cutting federal contracts designed to bolster domestic manufacturing capabilities. The contradiction is stark: on one hand, Trump has aggressively pursued import taxes, arguing that these measures will protect and strengthen American manufacturing jobs. Yet, on the other hand, his administration is systematically dismantling federal programs specifically created to support and enhance domestic industrial infrastructure. This approach raises critical questions about the administration's true commitment to American manufacturing. Are the tariffs merely a political gesture, or is there a coherent strategy behind these seemingly contradictory actions? The termination of manufacturing-focused federal contracts suggests a potential disconnect between rhetoric and practical policy implementation. As manufacturers and economic policy experts continue to analyze these developments, the long-term implications for American industrial competitiveness remain uncertain. The administration's approach appears to be creating more confusion than clarity in its economic strategy. MORE...

Green Revolution Sparks: Decatur Firm Launches Cutting-Edge Clean Energy Powerhouse

Manufacturing

2025-04-24 00:31:14

Decatur Welcomes Groundbreaking Clean Energy Innovation Hub In a significant milestone for sustainable technology, TCCI, a prominent manufacturing company based in Decatur, Illinois, proudly launched its state-of-the-art Clean Energy Innovation Hub on Wednesday morning. This cutting-edge facility marks a pivotal moment in the city's commitment to renewable energy and technological advancement. As the inaugural recipient of the Reimagining Energy initiative, TCCI's new hub represents a bold step forward in developing innovative clean energy solutions. The facility promises to be a beacon of technological progress, showcasing the potential for sustainable manufacturing and energy research. Local leaders and industry experts gathered to celebrate this momentous occasion, highlighting the hub's potential to drive economic growth and environmental sustainability in the Decatur region. The innovation center is expected to attract top talent and position the city as a forward-thinking hub for clean energy development. MORE...

Breakthrough in Biotech: LOTTE BIOLOGICS Launches Cutting-Edge ADC Manufacturing Hub

Manufacturing

2025-04-24 00:00:00

LOTTE BIOLOGICS Expands Global Biotech Partnerships with Strategic Manufacturing Agreement In a significant move to strengthen its international presence, LOTTE BIOLOGICS, led by CEO James Park, has announced a groundbreaking manufacturing collaboration with a prominent Asia-based biotechnology company. The strategic partnership, revealed on April 24th, marks an important milestone in the company's expansion strategy. The agreement underscores LOTTE BIOLOGICS' commitment to advancing biotechnological innovation and establishing robust manufacturing capabilities across the Asian region. By joining forces with a key regional biotech partner, the company aims to enhance its production infrastructure and accelerate the development of cutting-edge biological solutions. While specific details of the manufacturing agreement remain confidential, industry experts view this collaboration as a potential game-changer in the biotechnology landscape. The partnership is expected to leverage the strengths of both organizations, promising significant advancements in biological research and production technologies. MORE...

Biotech Breakthrough: FujiFilm Seals Massive $3B Manufacturing Partnership with Regeneron

Manufacturing

2025-04-23 23:06:17

FujiFilm Diosynth is set to embark on an ambitious decade-long partnership with Regeneron, manufacturing critical biologic medicines at its state-of-the-art Holly Springs facility. The cutting-edge manufacturing site, which is slated to commence operations in the current year, represents a significant milestone in pharmaceutical production capabilities. This strategic collaboration will enable FujiFilm Diosynth to leverage its advanced manufacturing technologies to produce Regeneron's complex biologic medications. The long-term agreement underscores both companies' commitment to advancing medical innovation and ensuring robust pharmaceutical supply chains. The Holly Springs facility, equipped with modern infrastructure and sophisticated biotechnology systems, is poised to become a key production hub for these important therapeutic treatments. By establishing this comprehensive manufacturing partnership, FujiFilm Diosynth and Regeneron are positioning themselves at the forefront of biologics production and healthcare innovation. MORE...

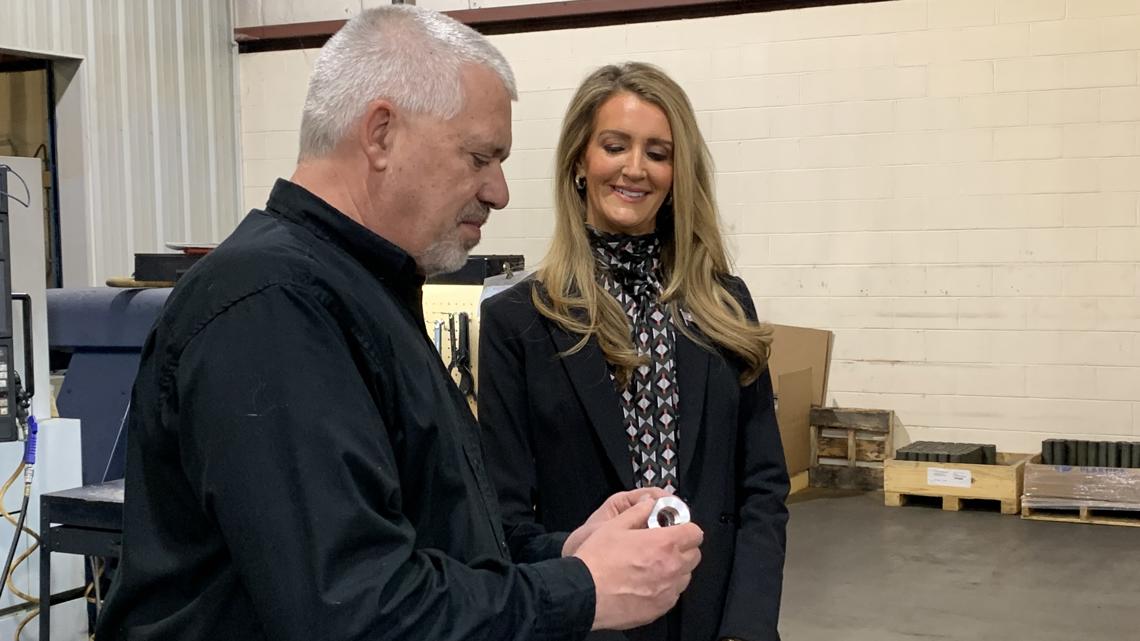

Trade Talks and Factory Floors: Loeffler's Pennsylvania Manufacturing Spotlight

Manufacturing

2025-04-23 21:20:00

Championing Economic Growth: Loeffler's Commitment to American Businesses Kelly Loeffler emerged as a strong advocate for economic revitalization, enthusiastically supporting President Trump's strategic economic policies. Her passionate stance highlighted the transformative potential of targeted tariffs and strategic regulatory reforms designed to empower small businesses and reinvigorate American manufacturing. By embracing these economic initiatives, Loeffler demonstrated her unwavering commitment to creating a robust business environment that would strengthen local enterprises and boost national economic resilience. She viewed these policies as critical tools for supporting entrepreneurs, protecting domestic industries, and creating meaningful opportunities for American workers. Her vocal support underscored a broader vision of economic empowerment, where smart trade policies and reduced bureaucratic barriers could unleash the innovative potential of American businesses and help them compete more effectively on the global stage. MORE...

AI Revolution: How Machine Learning is Transforming Microchip Production

Manufacturing

2025-04-23 20:53:45

Revolutionizing Microchip Manufacturing: A Cutting-Edge Plasma Chamber Innovation In the rapidly evolving world of semiconductor technology, a groundbreaking project is set to transform the landscape of microchip production. Researchers are developing advanced manufacturing systems for plasma chambers, targeting critical improvements in the precision and efficiency of microchip etching processes. This innovative initiative aims to address the complex challenges of semiconductor fabrication by reimagining the core infrastructure of plasma etching technology. By optimizing the design and functionality of plasma chambers, the project promises to enhance the accuracy, speed, and reliability of microchip manufacturing. The potential impact is significant, offering semiconductor manufacturers a pathway to more sophisticated and cost-effective production methods. As microchips become increasingly integral to modern technology, these improvements could drive substantial advancements in everything from consumer electronics to advanced computing systems. With a focus on pushing the boundaries of manufacturing precision, this project represents a crucial step forward in the ongoing technological revolution of semiconductor production. MORE...

Tech Boom: Missouri Poised to Surge into Manufacturing's Top Tier

Manufacturing

2025-04-23 20:30:00

Missouri is poised to become a powerhouse in technology manufacturing, according to a recent report by the Missouri Chamber Foundation. The state is projected to break into the top 10 states for tech manufacturing jobs within the next five years, signaling an exciting economic transformation. This promising forecast highlights Missouri's growing potential in the high-tech sector, suggesting a bright future for job seekers and businesses alike. The state is positioning itself as an emerging hub for cutting-edge manufacturing, potentially attracting innovative companies and skilled workers from across the nation. The projection not only demonstrates Missouri's commitment to technological advancement but also indicates a strategic approach to economic development. As the tech manufacturing landscape continues to evolve, Missouri stands ready to capitalize on emerging opportunities and establish itself as a key player in the industry. MORE...

Manufacturing Crossroads: GM CEO Mary Barra Calls for Urgent Policy Roadmap to Revive American Industrial Might

Manufacturing

2025-04-23 20:28:00

In a candid assessment of the current manufacturing landscape, General Motors CEO Mary Barra highlighted the potential for American manufacturers to successfully compete with China, but emphasized the critical need for clarity on Donald Trump's strategic economic plans and policies. Speaking at a recent industry conference, Barra suggested that while U.S. manufacturers have the capability to thrive in the global market, they require a comprehensive understanding of the incoming administration's economic roadmap. Her comments underscore the uncertainty and anticipation surrounding potential trade strategies that could significantly impact international manufacturing dynamics. The automotive industry leader's remarks reflect a broader sentiment among American manufacturers who are eager to navigate the complex terrain of international competition and trade relations. By gaining deeper insights into Trump's economic vision, companies can better position themselves to leverage potential opportunities and mitigate potential challenges in the global marketplace. MORE...

Trade Wars and Factory Floors: How Tariffs Are Reshaping Your Economic Reality

Manufacturing

2025-04-23 19:28:00

Cutting Through the Noise: Your Essential Guide to Understanding the Real Story In a world drowning in information and complex calculations, we're here to do the heavy lifting for you. Our mission is simple: strip away the complicated jargon and confusing statistics to deliver the insights that truly matter. We dive deep into the details, sifting through layers of complexity to extract the core information you need. No more getting lost in endless numbers or technical explanations. We translate the complicated into the clear, giving you a straightforward path to understanding. Whether you're seeking clarity on a complex topic or looking to make an informed decision, we break down the barriers. Our approach is direct, transparent, and focused on what's most important to you. We don't just present information—we make it meaningful, accessible, and actionable. Let us be your guide through the maze of data and rhetoric, helping you see the bigger picture with crystal-clear precision. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238