Robots on the Factory Floor: How Autonomous Mobile Robots Are Revolutionizing Manufacturing

Manufacturing

2025-04-09 00:00:00Content

Autonomous Mobile Robots (AMRs) are revolutionizing manufacturing automation by offering an incredibly versatile and user-friendly solution for businesses looking to streamline their operations. However, the key to successful AMR implementation lies in strategic planning and careful selection.

Manufacturers must approach AMR integration with a thoughtful mindset, carefully identifying the most suitable tasks and preparing their facilities to maximize the potential of these intelligent robotic systems. By conducting a thorough assessment of workflow challenges and operational requirements, companies can unlock the transformative power of AMR technology.

The true strength of AMRs lies in their adaptability. Unlike traditional fixed automation systems, these intelligent robots can seamlessly navigate dynamic work environments, quickly adjusting to changing production demands and facility layouts. This flexibility allows manufacturers to optimize their processes with minimal disruption and maximum efficiency.

Success with AMRs isn't just about purchasing the technology—it's about creating a comprehensive implementation strategy. Facilities must be carefully evaluated for potential obstacles, workflow patterns must be analyzed, and staff must be trained to work collaboratively with these advanced robotic assistants.

When approached strategically, AMRs can become a game-changing solution that enhances productivity, reduces manual labor, and drives significant operational improvements across manufacturing environments.

Revolutionizing Manufacturing: The Autonomous Mobile Robots Transformation

In the rapidly evolving landscape of industrial automation, manufacturers are increasingly turning to cutting-edge technologies that promise to reshape production environments. Autonomous Mobile Robots (AMRs) represent a groundbreaking solution that is redefining efficiency, flexibility, and operational intelligence in modern manufacturing facilities.Unleash the Power of Intelligent Automation: Transform Your Manufacturing Workflow Today!

The Rise of Autonomous Mobile Robots in Industrial Settings

The manufacturing sector is experiencing a profound technological revolution driven by autonomous mobile robots. These sophisticated machines are not merely technological novelties but strategic assets that fundamentally transform operational workflows. Unlike traditional fixed automation systems, AMRs offer unprecedented adaptability and intelligence, navigating complex industrial environments with remarkable precision and autonomy. Modern manufacturing demands unprecedented flexibility, and AMRs emerge as the perfect solution to meet these challenging requirements. These intelligent robotic systems can dynamically reconfigure themselves, seamlessly adapting to changing production demands without extensive infrastructure modifications. Their advanced sensor technologies and sophisticated navigation algorithms enable them to interact safely and efficiently within intricate industrial landscapes.Technical Architecture and Navigation Capabilities

The technological sophistication of autonomous mobile robots represents a quantum leap in industrial automation. These machines leverage complex sensor fusion technologies, integrating laser rangefinders, computer vision systems, and advanced machine learning algorithms to create real-time environmental maps and navigate intricate spaces with extraordinary accuracy. Each AMR functions as a sophisticated autonomous agent, capable of making instantaneous decisions based on complex environmental inputs. Their navigation systems utilize simultaneous localization and mapping (SLAM) technologies, allowing them to understand and interact with their surroundings dynamically. This enables them to optimize routes, avoid obstacles, and maintain consistent operational efficiency across diverse manufacturing environments.Economic and Operational Implications

Implementing autonomous mobile robots represents a strategic investment with multifaceted economic benefits. Beyond immediate productivity gains, these systems offer substantial long-term advantages in labor optimization, operational flexibility, and technological adaptability. Manufacturers can significantly reduce manual material handling costs while simultaneously improving workplace safety and operational consistency. The economic model of AMR implementation transcends traditional automation paradigms. By providing scalable, modular automation solutions, these robots enable manufacturers to incrementally upgrade their technological infrastructure without massive capital expenditures. Their plug-and-play nature allows rapid deployment and seamless integration into existing production ecosystems.Challenges and Strategic Considerations

While autonomous mobile robots present transformative potential, successful implementation requires meticulous strategic planning. Manufacturers must conduct comprehensive facility assessments, evaluate specific operational requirements, and develop robust integration strategies. This involves analyzing workflow complexities, understanding technological compatibility, and creating comprehensive training programs for human-robot collaboration. Critical considerations include infrastructure readiness, technological infrastructure, workforce training, and long-term scalability. Organizations must develop holistic approaches that view AMRs not as isolated technological solutions but as integral components of a broader digital transformation strategy. This requires cross-functional collaboration between engineering, operations, and strategic leadership teams.Future Trajectory of Autonomous Mobile Robotics

The future of autonomous mobile robots in manufacturing appears extraordinarily promising. Emerging technologies like advanced artificial intelligence, enhanced sensor capabilities, and more sophisticated machine learning algorithms will continue to expand their operational capabilities. We can anticipate increasingly intelligent, adaptable, and autonomous robotic systems that can handle progressively complex manufacturing challenges. Technological convergence between robotics, artificial intelligence, and industrial internet-of-things (IIoT) platforms will likely produce even more sophisticated autonomous mobile robots. These future systems will not just move materials but will actively participate in complex decision-making processes, providing unprecedented levels of operational intelligence and efficiency.RELATED NEWS

Manufacturing

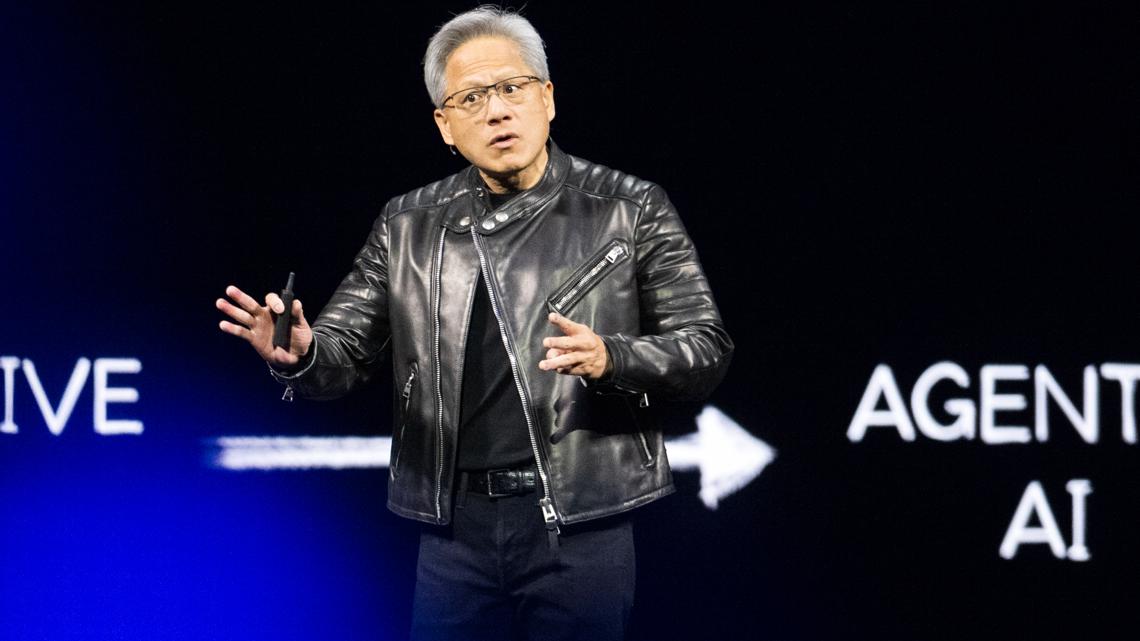

Tech Titan Nvidia Transforms Houston: Supercomputer Powerhouse Set to Revolutionize Local Manufacturing

2025-04-14 17:37:00

Manufacturing

Threads of Uncertainty: Can Trump's Trade Gambit Revive America's Apparel Manufacturing?

2025-03-27 04:01:00

Manufacturing

From Prototypes to Production: Inside Stratasys' Additive Manufacturing Revolution with Andrew Graves

2025-02-24 13:00:42