3D Printing Revolution: How Pratt & Whitney Is Transforming Engine Repair with Cutting-Edge Additive Manufacturing

Manufacturing

2025-04-09 00:00:00Content

Revolutionizing Manufacturing: Cutting-Edge Repair Solution Slashes Processing Time

In a groundbreaking advancement, a leading manufacturing company has unveiled an innovative additive repair solution that promises to transform industrial maintenance processes. This cutting-edge technology dramatically reduces processing time by an impressive 60%, marking a significant leap forward in manufacturing efficiency.

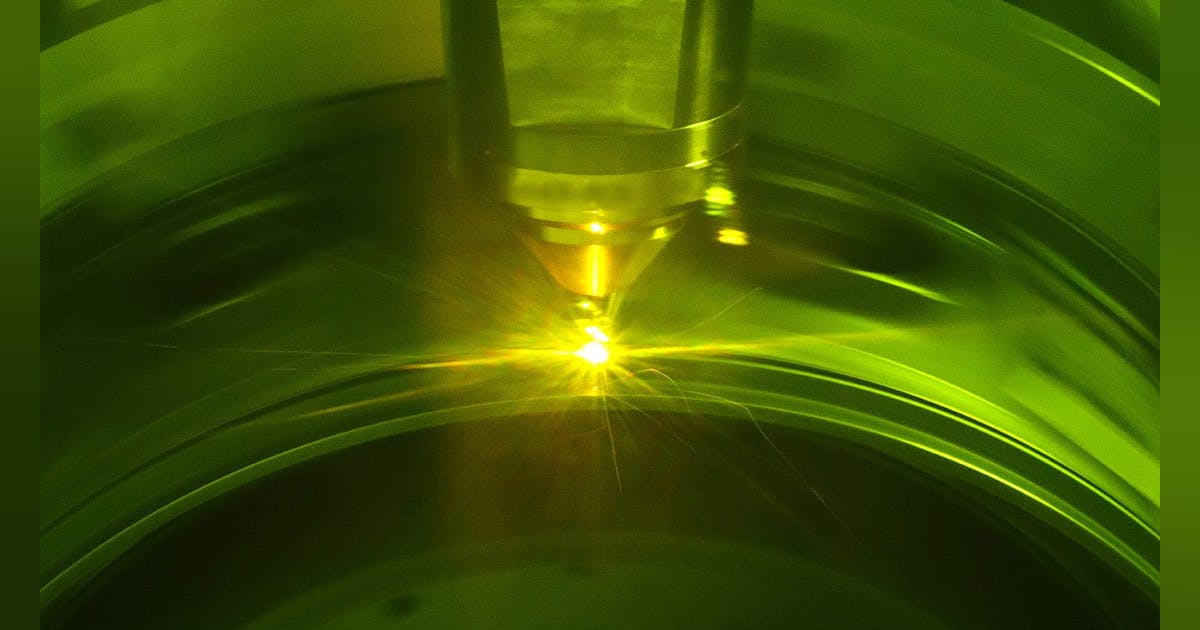

The breakthrough centers on an advanced 3D printing technique called Directed Energy Deposition, which enables unprecedented precision and speed in component repair and restoration. By leveraging this state-of-the-art method, manufacturers can now address equipment wear and damage with remarkable speed and accuracy.

This innovative approach not only accelerates repair workflows but also offers substantial cost savings and minimizes equipment downtime. Companies across various industries can now benefit from a more streamlined, technologically sophisticated repair process that enhances overall operational productivity.

The new solution represents a pivotal moment in manufacturing technology, demonstrating how advanced 3D printing techniques can revolutionize traditional maintenance and repair strategies. As industries continue to seek more efficient and cost-effective solutions, this breakthrough stands at the forefront of technological innovation.

Revolutionary Aerospace Manufacturing: The Future of Rapid Repair and 3D Printing Technology

In the rapidly evolving world of aerospace engineering, technological innovations are transforming how complex machinery is maintained and repaired. The intersection of advanced manufacturing techniques and cutting-edge repair solutions is creating unprecedented opportunities for efficiency, cost reduction, and performance optimization in the aerospace industry.Breakthrough Technologies Reshaping Aerospace Maintenance Strategies

Advanced Additive Manufacturing Techniques

The aerospace sector is experiencing a transformative revolution through sophisticated additive manufacturing methodologies. Directed Energy Deposition represents a groundbreaking approach that fundamentally reimagines component restoration and repair processes. This innovative technique allows engineers to reconstruct damaged components with unprecedented precision, dramatically reducing traditional repair timelines and minimizing operational downtime. Engineers are now capable of implementing intricate repair strategies that were previously considered impossible. By leveraging sophisticated 3D printing technologies, manufacturers can recreate complex geometries and restore critical aerospace components with microscopic accuracy. The ability to rebuild and reinforce mechanical parts at the molecular level represents a quantum leap in maintenance capabilities.Processing Time Optimization Strategies

The implementation of advanced repair solutions has yielded remarkable efficiency gains. Traditional repair methodologies often required extensive manual interventions and prolonged processing periods. However, the new generation of additive repair technologies promises to reduce processing times by an extraordinary margin of over 60%. This dramatic reduction in repair duration translates into substantial economic advantages for aerospace organizations. By minimizing equipment downtime and streamlining maintenance workflows, companies can significantly enhance operational productivity and reduce overall maintenance expenditures. The technological breakthrough represents a paradigm shift in how aerospace components are restored and maintained.Technological Implications and Industry Transformation

The convergence of Directed Energy Deposition and advanced 3D printing methodologies signals a profound transformation in aerospace manufacturing. These technologies are not merely incremental improvements but represent a fundamental reimagining of repair and restoration processes. Aerospace engineers and manufacturers are now equipped with tools that enable unprecedented levels of precision and efficiency. The ability to rapidly reconstruct complex components with minimal material waste represents a significant technological milestone. Moreover, these innovations contribute to sustainability efforts by reducing material consumption and extending the operational lifecycle of critical aerospace equipment.Future Perspectives and Technological Evolution

As additive manufacturing technologies continue to mature, the aerospace industry can anticipate even more sophisticated repair and restoration capabilities. The ongoing research and development in this domain promise increasingly refined techniques that will further optimize maintenance strategies. The potential applications extend beyond immediate repair scenarios, potentially revolutionizing how aerospace components are designed, manufactured, and maintained. By embracing these transformative technologies, organizations can position themselves at the forefront of technological innovation, driving efficiency and performance to unprecedented levels.RELATED NEWS

Manufacturing

Tech Titans Forge Future: Accenture and Siemens Unleash 7,000-Worker Digital Manufacturing Revolution

2025-03-31 05:59:00

Manufacturing

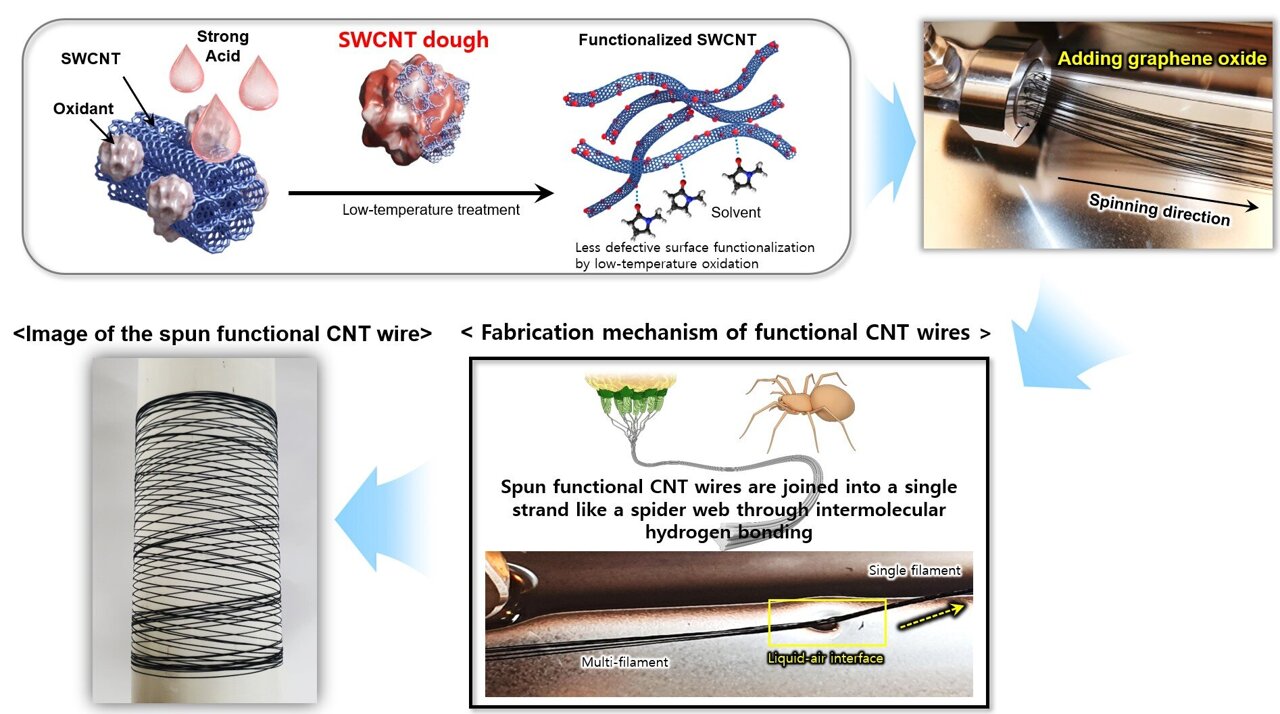

Threads of the Future: How Everyday Fibers Are Becoming High-Tech Wearable Wires

2025-03-19 15:06:04

Manufacturing

Tariff Takedown: Pfizer's Bold Strategy to Bring Drug Production Back Home

2025-03-04 04:12:53