Forging America's Future: How Warriors Are Rebuilding the Manufacturing Workforce

Manufacturing

2025-04-17 08:17:41

Nestled in the heart of Barrio Logan, Workshops for Warriors stands as a beacon of hope and innovation in the American manufacturing landscape. This dynamic training center is more than just a school—it's a transformative platform where veterans and transitioning service members breathe new life into the nation's industrial capabilities. The facility offers comprehensive, hands-on training programs that equip students with critical skills in welding, machining, and advanced manufacturing technologies. By providing veterans with cutting-edge technical education, Workshops for Warriors is not just teaching trades, but rebuilding America's manufacturing prowess from the ground up. Each student becomes a craftsman, learning precision techniques that range from intricate metal fabrication to sophisticated computer-controlled machining. The program goes beyond simple job training; it's about empowering veterans to become skilled professionals who can drive industrial innovation and economic revitalization. Through its rigorous curriculum and state-of-the-art equipment, the center transforms military experience into technical expertise, creating a powerful pathway for veterans to transition into high-demand manufacturing careers. Workshops for Warriors isn't just rebuilding machinery—it's rebuilding lives and strengthening the backbone of American industry. MORE...

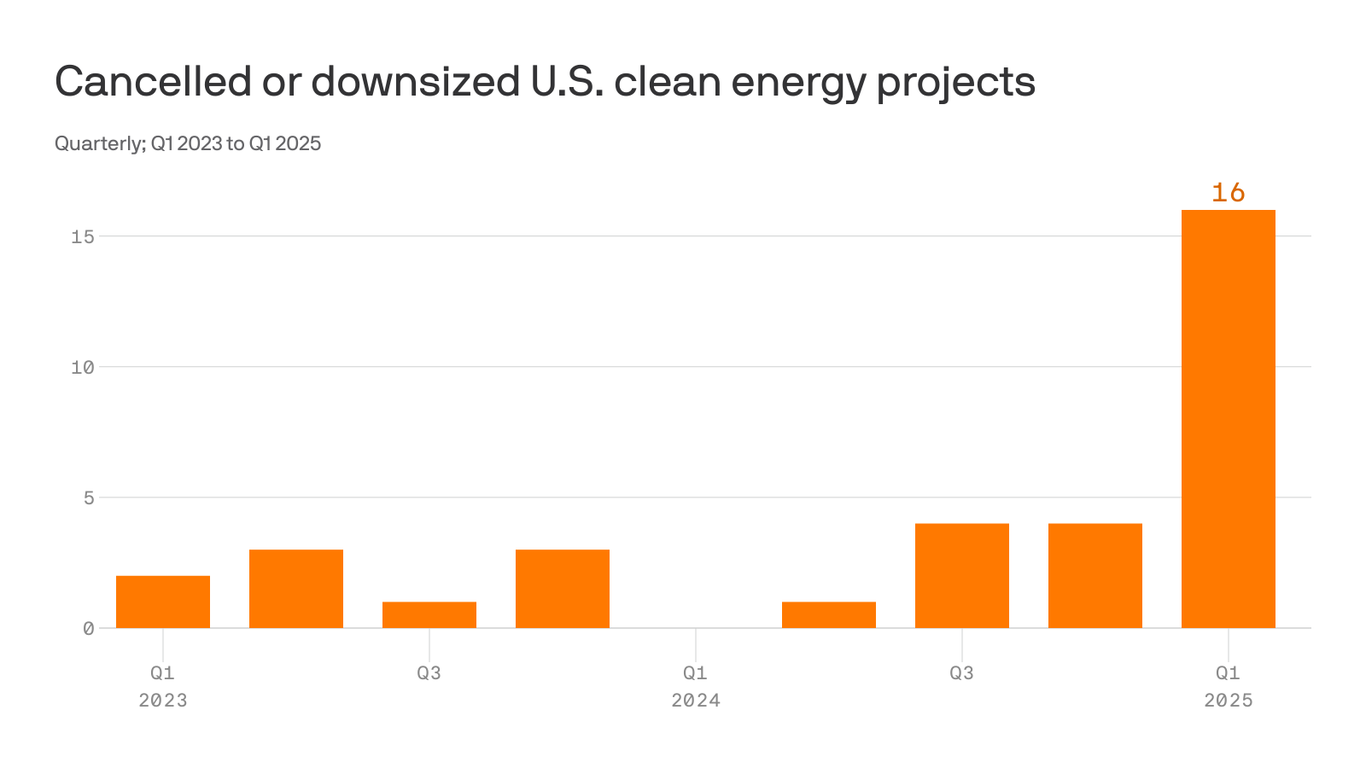

Green Energy Exodus: Massive Project Cancellations Signal Urgent Industry Shift

Manufacturing

2025-04-17 08:00:00

In a striking trend reflecting economic uncertainty, manufacturers have dramatically scaled back expansion plans, with 16 companies canceling or postponing factory projects since the start of 2024. This significant pullback signals growing caution in the industrial sector, as businesses reassess their growth strategies amid complex market conditions. The sudden reversal of factory plans highlights the delicate balance companies are navigating between potential growth opportunities and economic risks. Factors such as fluctuating market demand, rising construction costs, and uncertain supply chain dynamics appear to be driving these strategic retreats. Industry experts suggest that this trend could be a bellwether for broader economic challenges, indicating that businesses are adopting a more conservative approach to capital investments. The widespread nature of these project cancellations spans multiple sectors, from manufacturing to technology, underscoring the pervasive economic hesitation. While the exact motivations vary by company, the consistent theme seems to be a careful reevaluation of expansion strategies in an increasingly unpredictable business landscape. Investors and economic analysts are closely watching these developments as potential indicators of future economic momentum. MORE...

Bayer Doubles Down: $44 Million Boost Transforms Pennsylvania's Manufacturing Landscape

Manufacturing

2025-04-17 07:13:02

Bayer Unveils Cutting-Edge Expansion in Myerstown, Signaling Major Growth and Investment Bayer has marked a significant milestone with the grand opening of an impressive 70,000 square foot facility expansion at its Myerstown location. The strategic development, backed by a substantial USD 44 million investment in 2022, underscores the company's commitment to innovation and regional economic growth. This state-of-the-art expansion represents more than just additional square footage—it's a testament to Bayer's ongoing dedication to advancing manufacturing capabilities and strengthening its operational infrastructure. The new facility promises to enhance production efficiency, create local job opportunities, and reinforce the company's competitive position in the industry. By making this substantial investment, Bayer demonstrates its confidence in the Myerstown facility and its potential to drive future technological and manufacturing advancements. The expansion signals a promising future for both the company and the local community, highlighting Bayer's long-term strategic vision. MORE...

Tariff Tango: Can Trump's Trade Gambit Revive America's Industrial Heartland?

Manufacturing

2025-04-17 07:00:00

While President Biden might hope for a straightforward resolution, the reality of the current situation is far more nuanced and complex. The challenges facing the administration are multifaceted, defying simple solutions or quick fixes. Political analysts and policy experts suggest that the path forward requires careful navigation, balancing competing interests and addressing underlying systemic issues. The complexity of the matter goes beyond surface-level interpretations, demanding a sophisticated and strategic approach. What initially seemed like a clear-cut scenario has revealed layers of complexity that challenge conventional thinking. Each potential solution brings with it a new set of considerations, making it increasingly difficult to chart a definitive course of action. The president's team must now grapple with these intricate dynamics, recognizing that simplistic narratives or one-size-fits-all strategies are unlikely to yield meaningful progress. Instead, a more thoughtful, adaptive approach will be necessary to effectively address the challenges at hand. MORE...

Chip Giant TSMC Unveils Q1 2025 Performance: Inside the Silicon Revolution

Manufacturing

2025-04-17 06:59:25

TSMC Unveils Strategic Insights in Latest Earnings Presentation

Taiwan Semiconductor Manufacturing Company Limited (TSMC) has released a comprehensive slide deck that offers a deep dive into the company's strategic vision and financial performance during their Q1 2025 earnings call. This meticulously crafted presentation provides investors, analysts, and industry observers with a nuanced understanding of the semiconductor giant's current market position and future trajectory.

The slide deck, which serves as a critical communication tool, highlights TSMC's ongoing commitment to technological innovation, operational excellence, and sustained growth in the rapidly evolving semiconductor landscape. By transparently sharing key financial metrics, technological advancements, and strategic initiatives, the company continues to demonstrate its leadership in the global semiconductor manufacturing ecosystem.

Investors and technology enthusiasts alike will find the presentation a valuable resource for gaining insights into TSMC's forward-looking strategies, market adaptations, and potential growth opportunities in an increasingly complex and competitive technological environment.

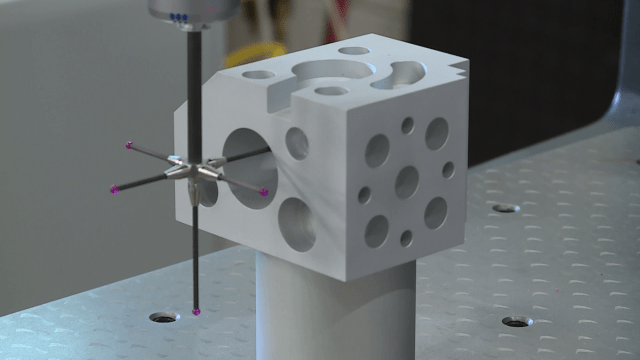

MORE...Manufacturing Boom: How Las Vegas Residents Are Riding the Industrial Wave

Manufacturing

2025-04-17 06:18:15

LAS VEGAS (KLAS) – In a dazzling display of innovation and skill, local students from the Las Vegas area are transforming ordinary metal into extraordinary creations. With precision and creativity, these young makers are crafting intricate metal objects that have caught the attention of nearly 200 potential employers. The workshop buzzes with energy as students wield advanced tools, their ruby-tipped implements gliding effortlessly across metal surfaces. Each carefully crafted piece tells a story of technical prowess and artistic vision, showcasing the remarkable talents of the next generation of makers and engineers. The gleaming results of their hard work shine brightly, not just as metal objects, but as testaments to the students' dedication, creativity, and emerging technical expertise. Employers watch with keen interest, recognizing the potential of these young innovators who are reshaping the future of manufacturing and design. MORE...

Beauty Shake-Up: Boy Smells' Brand Stumble, LVMH's Earnings Surge, and the Recycling Revolution Transforming Cosmetics

Manufacturing

2025-04-17 04:02:00

In a revealing conversation on the Glossy Beauty podcast, Pact Collective's executive director Carly Snider peels back the layers of complexity surrounding beauty product recycling. Diving deep into the industry's most pressing sustainability challenges, Snider offers an insider's perspective on the intricate world of packaging waste and innovative recycling solutions. The podcast explores the nuanced journey of empty beauty packaging, shedding light on Pact Collective's groundbreaking efforts to transform waste into opportunity. Snider discusses the organization's ambitious plans to expand collection efforts, with strategic placement of recycling bins in libraries and universities - bringing sustainable practices directly to communities where environmental consciousness is taking root. What sets Pact Collective apart is its commitment to pre-competitive collaboration, bringing together beauty brands that might otherwise be rivals. By uniting around a shared environmental mission, these companies are proving that sustainability can be a powerful catalyst for industry-wide change. Listeners will gain insights into the complex process of recycling beauty packaging, the challenges of material diversity, and the innovative approaches being developed to create a more circular economy in the beauty industry. Snider's passionate discussion highlights the critical importance of collective action in addressing environmental sustainability. MORE...

Manufacturing Momentum: Vermont Leaders Converge to Forge Economic Strategy

Manufacturing

2025-04-17 04:00:00

Vermont Manufacturing Leaders Converge at Statehouse to Showcase Economic Impact

In a powerful display of industry solidarity, more than 100 manufacturing executives descended upon the Vermont Statehouse on April 2nd, transforming the legislative venue into a vibrant hub of economic dialogue and strategic networking.

The event, Vermont Manufacturing Day, was meticulously organized by key industry associations including the Vermont Chamber of Commerce, Associated Industries of Vermont, and Regional Development Corporations. Their collective mission was clear: to illuminate the critical role manufacturing plays in driving Vermont's economic engine.

Industry leaders seized this unique opportunity to directly engage with state legislators, sharing compelling insights into how manufacturing contributes significantly to the state's economic landscape. The gathering served not just as a meeting, but as a platform for advocacy, education, and collaborative potential.

By bringing together diverse manufacturing professionals, the event underscored the sector's resilience, innovation, and fundamental importance to Vermont's economic prosperity.

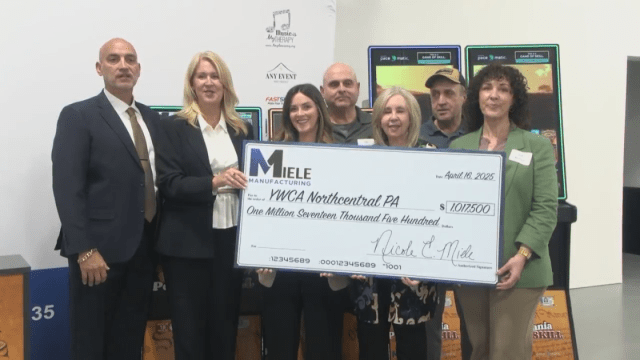

MORE...Local Manufacturing Giant Transforms Community: Miele Drops Massive $1M Lifeline to County YMCA

Manufacturing

2025-04-17 03:22:30

In a remarkable display of community support, the YWCA of Lycoming County received a transformative million-dollar donation on Wednesday evening. The substantial financial gift will enable the organization to undertake critical renovations that promise to enhance their facilities and expand their community services. The generous contribution marks a significant milestone for the local women's organization, signaling strong community commitment to supporting women's empowerment and social services. While specific details about the donor and the exact renovation plans were not immediately disclosed, the donation represents a substantial boost to the YWCA's ongoing mission. This substantial financial support is expected to help modernize the organization's infrastructure, potentially improving their ability to provide essential programs and support services to women and families in Lycoming County. The donation underscores the community's recognition of the YWCA's vital role in local social support networks. Local leaders and YWCA representatives are likely to be excited about the potential impact this donation will have on their future operations and community outreach efforts. MORE...

Tariff Tango: Can America Revive Its Manufacturing Muscle?

Manufacturing

2025-04-17 03:12:39

Tariffs Unveiled: The Real Impact on Your Wallet and American Manufacturing

Let's face it: tariff discussions can feel like a broken record. But beneath the repetitive rhetoric lies a critical economic narrative that directly affects your daily life and the future of American production.

While many tune out when trade policies are mentioned, understanding the nuanced implications of tariffs is more crucial now than ever. These economic tools aren't just abstract government strategies—they're mechanisms that can reshape entire industries, influence consumer prices, and potentially redefine America's manufacturing landscape.

The burning question remains: Can the United States truly resurrect its manufacturing prowess on a scale that meets modern economic demands? It's a complex puzzle involving global competition, technological innovation, labor costs, and strategic economic planning.

As consumers and citizens, we're not just passive observers in this economic drama. Our purchasing choices, support for local industries, and understanding of trade dynamics can significantly influence the trajectory of American manufacturing.

The journey to revitalizing domestic production is challenging but not impossible. It requires a delicate balance of smart policy, innovative thinking, and collective commitment to rebuilding our industrial capabilities.

MORE...- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238

_(4).png)