Beyond Waste: How ABB Is Revolutionizing Manufacturing's Circular Economy

Manufacturing

2025-04-09 10:00:11Content

ABB is revolutionizing manufacturing sustainability by spearheading a groundbreaking approach to circular economy practices. The global technology leader is transforming industrial waste management through innovative solutions that help manufacturers dramatically reduce environmental impact and optimize resource utilization.

By pioneering cutting-edge technologies and strategic circular design principles, ABB is enabling companies to reimagine their production processes. Their innovative approach goes beyond traditional waste reduction, focusing on creating closed-loop systems that minimize material waste, reduce carbon footprint, and drive economic efficiency.

Through intelligent automation, advanced analytics, and sustainable engineering, ABB is empowering manufacturers to transition from linear to circular production models. This transformative strategy not only supports environmental conservation but also helps businesses unlock new opportunities for cost savings and competitive advantage in an increasingly sustainability-focused global market.

The company's commitment to circularity represents a significant leap forward in industrial sustainability, demonstrating how technological innovation can be a powerful catalyst for positive environmental change.

Revolutionizing Manufacturing: ABB's Groundbreaking Circular Economy Strategy

In the rapidly evolving landscape of industrial innovation, manufacturers are increasingly confronting the critical challenge of sustainability. As global resources become more constrained and environmental concerns intensify, companies are seeking transformative approaches to reduce waste and optimize production processes.Pioneering Sustainable Manufacturing Through Innovative Circular Solutions

The Circular Economy Imperative in Modern Manufacturing

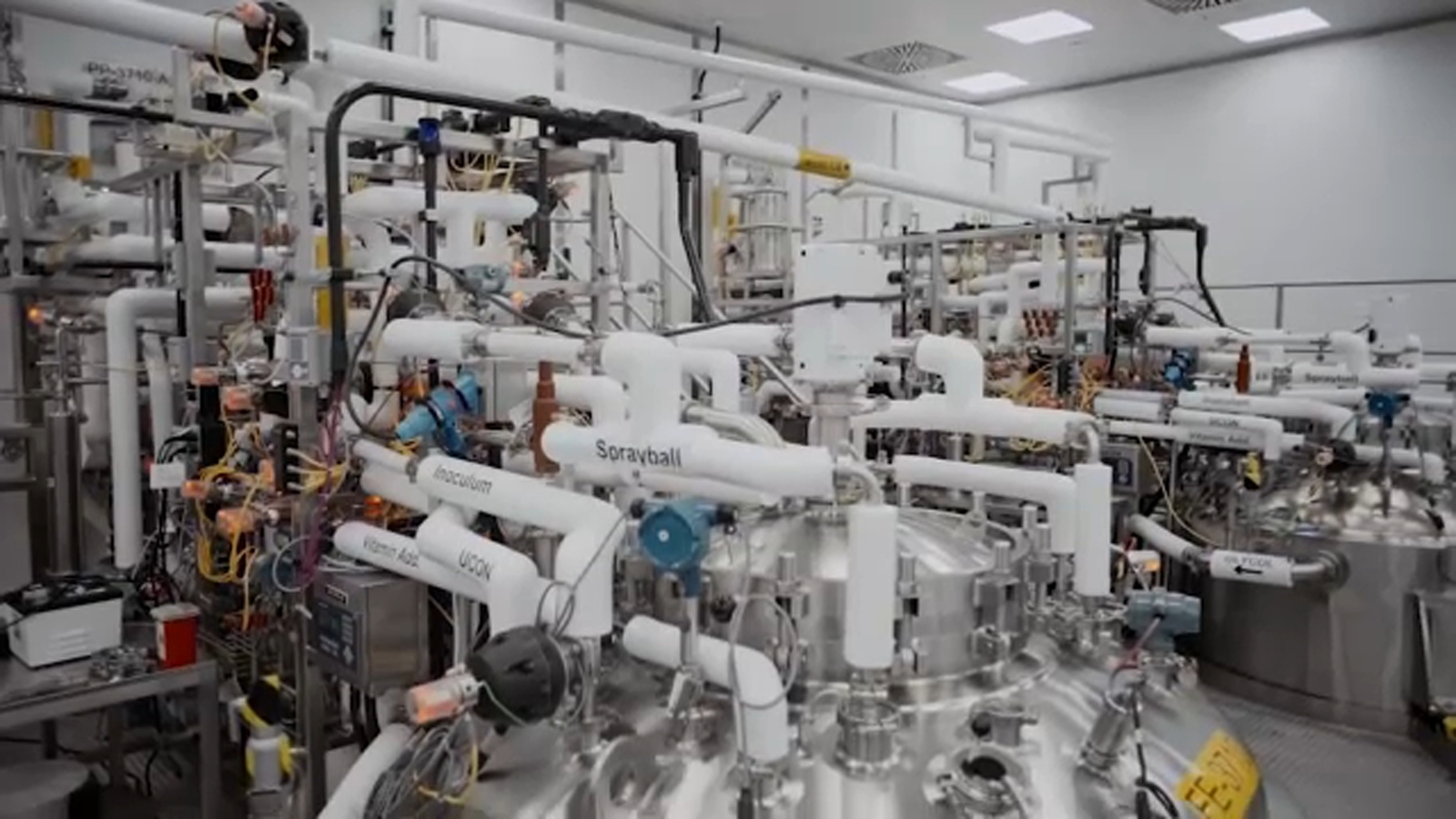

The manufacturing sector stands at a pivotal moment of technological and environmental transformation. Traditional linear production models, characterized by take-make-dispose approaches, are rapidly becoming obsolete. ABB's innovative strategy represents a paradigm shift, demonstrating how technological intelligence can fundamentally reimagine industrial resource management. Industrial ecosystems are increasingly recognizing that waste is not an inevitable byproduct but a design challenge waiting to be solved. By implementing sophisticated tracking, monitoring, and optimization technologies, manufacturers can dramatically reduce material inefficiencies and create closed-loop systems that regenerate resources.Technological Innovations Driving Waste Reduction

Advanced digital technologies are becoming the cornerstone of sustainable manufacturing strategies. ABB's approach leverages cutting-edge automation, artificial intelligence, and real-time data analytics to identify and eliminate waste streams at their source. These technologies enable unprecedented precision in resource allocation, predictive maintenance, and process optimization. Intelligent sensor networks and machine learning algorithms can now detect microscopic inefficiencies that human observers might miss. By creating granular visibility into production processes, manufacturers can make data-driven decisions that minimize material waste, energy consumption, and environmental impact.Economic and Environmental Synergies

The circular economy is not just an environmental imperative but a significant economic opportunity. Companies that successfully implement circular strategies can unlock substantial cost savings, enhance brand reputation, and create competitive differentiation. ABB's approach demonstrates that sustainability and profitability are not mutually exclusive but deeply interconnected. By redesigning industrial processes to prioritize resource regeneration, companies can transform potential waste into valuable inputs. This systemic approach creates resilient supply chains, reduces dependency on virgin materials, and generates new revenue streams through innovative recycling and repurposing strategies.Global Impact and Future Perspectives

ABB's circular economy initiatives represent more than a technological solution—they embody a fundamental reimagining of industrial production. As global manufacturers confront escalating environmental challenges, such innovative approaches provide a blueprint for sustainable transformation. The scalability of these technologies suggests a profound potential for global impact. By demonstrating the economic and environmental viability of circular manufacturing, ABB is not just solving immediate industrial challenges but reshaping entire industrial ecosystems for a more sustainable future.RELATED NEWS

Manufacturing

Brewing Success: Milo's Tea Unveils State-of-the-Art Spartanburg Manufacturing Hub

2025-04-22 19:56:59

Manufacturing

Supply Chain Revolution: CADDi Secures $38M to Supercharge Manufacturing Efficiency

2025-03-27 20:45:13

Manufacturing

Chip Giant TSMC Defies Trade Tensions: Massive $10.7B Q1 Windfall Despite US Tariff Challenges

2025-04-17 12:03:45