Trade War Fallout: U.S. Manufacturing Takes Another Hit

Manufacturing

2025-05-01 15:58:00

The manufacturing sector is facing a perfect storm of economic challenges, with producers grappling with a series of critical setbacks. Industry leaders are reporting a dramatic decline in production levels, coupled with escalating material expenses that are squeezing profit margins. The situation is further complicated by a significant downturn in both import and export activities, signaling broader economic headwinds. Manufacturers across various industries are feeling the pinch as production lines slow down and operational costs continue to rise. The combination of shrinking output, increased raw material prices, and reduced international trade is creating a challenging landscape for businesses struggling to maintain their competitive edge. This multifaceted economic pressure is forcing companies to reassess their strategies and seek innovative solutions to navigate the current market turbulence. MORE...

Industrial Sector Stalls: Trump Tariffs Trigger Manufacturing Gridlock

Manufacturing

2025-05-01 15:27:27

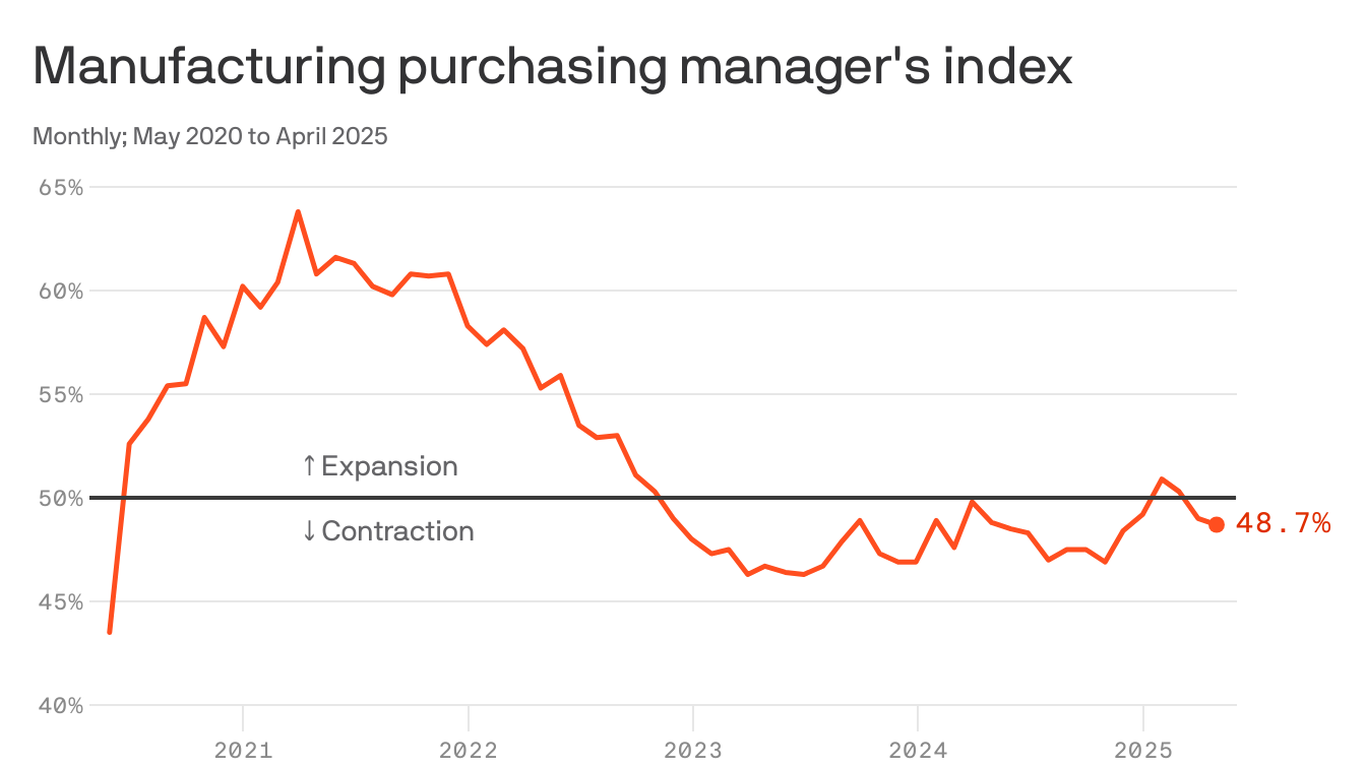

Manufacturing Stumbles as Trade Tensions Cast Long Shadow The U.S. manufacturing sector experienced a notable downturn in April, with business confidence wavering amid escalating trade tensions and uncertainty surrounding President Trump's tariff policies. Economic indicators suggest that manufacturers are growing increasingly cautious, as the complex global trade landscape continues to create challenges for industrial production and strategic planning. Key economic data reveals a marked decline in manufacturing activity, reflecting the broader economic anxieties triggered by ongoing trade disputes. Companies are finding themselves caught in a delicate balancing act, weighing the potential risks and opportunities presented by the current geopolitical climate. The impact of tariffs has been particularly pronounced, with many businesses reassessing their supply chains, production strategies, and investment decisions. This uncertainty is creating a ripple effect across various manufacturing subsectors, from automotive to technology and beyond. Economists and industry experts are closely monitoring these developments, recognizing that the manufacturing sector's performance is often a critical bellwether for overall economic health and future growth prospects. MORE...

Factory Floor Secrets: Why Manufacturing Pros Love Their Career Path

Manufacturing

2025-05-01 15:12:18

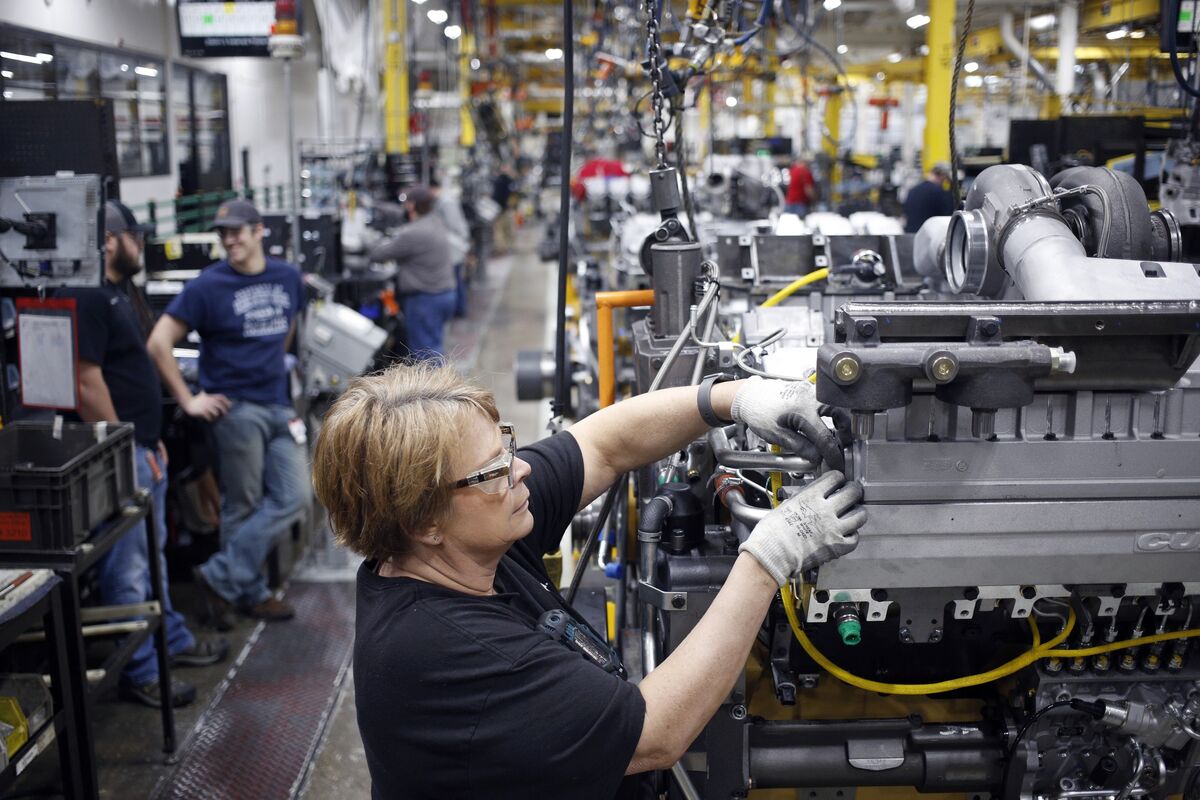

Manufacturing: A Career Path with Overwhelming Potential and Satisfaction A recent industry survey reveals an overwhelmingly positive sentiment among professionals in the manufacturing sector. An impressive 80% of women and 81% of men currently working in manufacturing are not just satisfied with their career choice, but are enthusiastic advocates who would readily recommend the field to others. These compelling statistics highlight the growing appeal and promising opportunities within the manufacturing industry. The near-equal endorsement from both female and male professionals underscores the sector's inclusive nature and potential for diverse talent. Such high recommendation rates suggest that manufacturing offers rewarding experiences, competitive opportunities, and a sense of professional fulfillment that transcends gender boundaries. For those considering a career path with stability, innovation, and growth, the manufacturing industry presents an exciting and promising landscape. The survey's results serve as a powerful testament to the sector's ability to engage, challenge, and satisfy its workforce. MORE...

Factory Floor Fallout: Manufacturing's Grim April Signals Economic Headwinds

Manufacturing

2025-05-01 14:04:23

The U.S. manufacturing sector continued its downward trajectory in April, facing persistent challenges that are reshaping the industrial landscape. Ongoing trade tensions and complex supply chain disruptions are creating a perfect storm of economic pressure, with manufacturers grappling with elevated input costs and strategic uncertainties. The latest economic indicators reveal a manufacturing environment under significant strain, where tariffs and global trade complexities are forcing companies to reassess their production strategies. Input prices remain stubbornly high, reflecting the intricate web of international trade barriers and logistical challenges that are squeezing profit margins and testing the resilience of American manufacturers. As businesses navigate this turbulent economic terrain, the manufacturing contraction signals broader concerns about industrial productivity and economic adaptability. The ongoing pressures underscore the need for innovative approaches to supply chain management and strategic trade policy that can help revitalize the sector's growth potential. MORE...

Solar Giant Canadian Solar Squeezed: Tariff Pressures Trigger Potential Manufacturing Exodus

Manufacturing

2025-05-01 14:00:48

Canadian Solar Struggles with Challenging Market Conditions in First Quarter In a stark revelation of the current solar industry landscape, Canadian Solar has reported a significant decline in profits for the first quarter of 2025, highlighting the complex challenges facing the renewable energy sector. The company cited two primary obstacles: formidable trade barriers and a pronounced supply-demand imbalance that has dramatically impacted its financial performance. The solar technology manufacturer is grappling with unprecedented market pressures that have squeezed its bottom line. Trade restrictions have created substantial hurdles for the company's global operations, while an unbalanced market dynamic has further complicated its ability to maintain previous profit levels. Industry analysts suggest these challenges reflect broader issues within the solar manufacturing ecosystem, pointing to global economic uncertainties and shifting renewable energy dynamics. Canadian Solar's experience serves as a critical indicator of the ongoing transformation and potential volatility in the green energy market. Despite the current setbacks, the company remains committed to navigating these challenging conditions and continues to explore strategies for resilience and recovery in an increasingly competitive global landscape. MORE...

Factory Floor Alarm: U.S. Manufacturing Hits Lowest Gear Since Fall

Manufacturing

2025-05-01 14:00:00

The U.S. manufacturing sector experienced a significant downturn in April, signaling ongoing challenges in the industrial landscape. Factory activity contracted sharply, marking the most substantial decline in five months and revealing the deepest production slowdown since the height of the pandemic in 2020. Manufacturers are grappling with lean order books, which have triggered a dramatic reduction in industrial output. This contraction reflects broader economic uncertainties, including persistent supply chain disruptions, fluctuating demand, and cautious business investment strategies. The steep decline suggests that the manufacturing sector continues to face headwinds, with businesses struggling to maintain momentum in a complex economic environment. Analysts are closely monitoring these trends, as they could potentially indicate broader economic challenges ahead. While the current situation presents significant challenges, it also offers insights into the resilience and adaptability of the U.S. manufacturing industry as it navigates through uncertain economic conditions. MORE...

Manufacturing Meltdown: UK Industry Buckles Under Global Trade Tensions

Manufacturing

2025-05-01 13:53:14

The U.S. manufacturing sector is facing mounting challenges as trade tensions and supply chain disruptions continue to erode industry confidence. Recent economic indicators suggest that ongoing tariffs are exacerbating existing pressures, creating a complex landscape for manufacturers navigating an increasingly uncertain global market. Demand for manufactured goods has been steadily declining, with businesses struggling to maintain production levels amid volatile economic conditions. The combination of trade barriers and unpredictable supply chains is forcing companies to reassess their strategic approaches and operational models. Manufacturers are experiencing significant strain as they attempt to balance rising production costs, reduced consumer demand, and the ongoing impact of international trade policies. The current economic environment demands unprecedented adaptability and strategic planning from industry leaders. Experts warn that these challenges could have long-term implications for the U.S. manufacturing sector, potentially reshaping industrial strategies and global competitiveness. Companies are increasingly exploring alternative supply chain solutions and seeking ways to mitigate the financial pressures created by current trade restrictions. As the manufacturing landscape continues to evolve, businesses must remain agile and innovative to survive in this challenging economic climate. The interplay of tariffs, supply chain uncertainties, and fluctuating market demands presents both significant obstacles and potential opportunities for forward-thinking manufacturers. MORE...

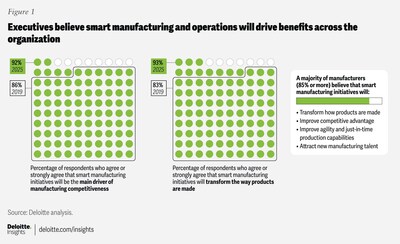

Smart Factories: The Game-Changing Tech Transforming Industry, But Funding Gaps Remain

Manufacturing

2025-05-01 13:01:00

In a groundbreaking survey by Deloitte, the transformative power of smart manufacturing has emerged as a critical competitive advantage for businesses, while simultaneously highlighting the need for strategic investment and thoughtful implementation. The research reveals that forward-thinking manufacturers are increasingly embracing advanced technologies to revolutionize their production processes. Smart manufacturing isn't just a trend—it's becoming a fundamental strategy for companies seeking to stay ahead in a rapidly evolving industrial landscape. Key findings from the survey underscore the significant potential of smart manufacturing technologies. Companies that successfully integrate intelligent systems are experiencing remarkable improvements in operational efficiency, product quality, and overall productivity. These technologies, including artificial intelligence, Internet of Things (IoT) sensors, and advanced analytics, are reshaping traditional manufacturing paradigms. However, the survey also illuminates a crucial challenge: while many organizations recognize the potential of smart manufacturing, many struggle with effective implementation. Successful digital transformation requires more than just technological investment—it demands a comprehensive approach that includes workforce training, cultural adaptation, and strategic planning. Experts recommend that businesses take a holistic approach to smart manufacturing adoption. This involves not only investing in cutting-edge technologies but also developing a robust ecosystem of skills, processes, and organizational capabilities that can fully leverage these innovative tools. As manufacturing continues to evolve, those companies that can effectively integrate smart technologies will likely gain a significant competitive edge. The Deloitte survey serves as a compelling call to action for manufacturers to embrace digital transformation with vision, commitment, and strategic insight. MORE...

Digital Dominance: How Tech Titans and Differently-Abled Innovators Are Reshaping the Global Landscape

Manufacturing

2025-05-01 13:00:00

In the rapidly evolving landscape of digital technology, each new CNC machine and digital device introduces a potential cybersecurity vulnerability. While this might sound alarming, there's a silver lining: innovative technologies are simultaneously emerging as powerful shields against these digital threats. Modern businesses are discovering that the same technological advancements that create potential security risks can also be leveraged to enhance their digital defense strategies. From advanced AI-driven threat detection to sophisticated machine learning algorithms, companies now have unprecedented tools to proactively protect their digital infrastructure. The key lies in staying ahead of the curve—understanding that every technological integration requires a comprehensive security approach. By embracing cutting-edge protective technologies alongside new digital devices, organizations can transform potential vulnerabilities into opportunities for robust cybersecurity. As digital ecosystems become increasingly complex, the ability to adapt and implement smart, dynamic security measures will be crucial for businesses seeking to thrive in an interconnected world. MORE...

Manufacturing Boost: Trump's Bold Move Doubles 'Made in America' Loan Limits

Manufacturing

2025-05-01 11:50:53

As the United States navigates complex trade dynamics and President Donald Trump's push to revitalize domestic manufacturing, a timely legislative proposal has emerged. The Made in America Manufacturing Finance Act arrives at a critical moment, promising to bolster the nation's industrial sector and support local producers. With strategic tariffs and a renewed focus on homegrown production, this proposed legislation couldn't be more perfectly positioned. Sponsors of the bill argue that it represents a crucial step toward strengthening American manufacturing capabilities, providing financial support and incentives for businesses committed to producing goods within U.S. borders. The act comes at a pivotal time when economic nationalism and domestic production are at the forefront of national economic strategy. By addressing financial challenges and creating supportive frameworks for manufacturers, the legislation aims to transform rhetoric about American manufacturing into tangible economic opportunities. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238