Furniture Frontiers: How US Manufacturers Are Reshaping Global Design and Trade

Manufacturing

2025-05-06 17:10:57

Navigating Challenges: How Tariffs Are Reshaping the U.S. Furniture Market The American furniture industry is experiencing significant disruption as trade tariffs create complex sourcing challenges for businesses across the sector. Manufacturers and retailers are grappling with unprecedented obstacles in procuring materials and products, with many finding it increasingly difficult to maintain traditional supply chains. These tariffs have forced furniture industry leaders to make critical strategic decisions, often compelling them to seek alternative sourcing methods or absorb substantial additional costs. Some businesses have been particularly hard-hit, struggling to find domestic alternatives for specialized components and materials that were previously imported at more competitive prices. The ripple effects are profound, potentially impacting everything from product pricing to design innovation. Small to medium-sized furniture businesses are especially vulnerable, as they often lack the financial flexibility to quickly adapt to these rapidly changing economic conditions. As the industry continues to navigate these challenging waters, furniture manufacturers and retailers are being compelled to rethink their sourcing strategies, explore domestic production options, and find creative solutions to maintain competitiveness in an increasingly complex global marketplace. MORE...

Industrial Renaissance: Pennsylvania Towns Secure Massive State Funding Boost

Manufacturing

2025-05-06 17:05:54

In a bold move to revitalize Pennsylvania's economic landscape, Governor Josh Shapiro and Department of Community and Economic Development Secretary Rick Siger unveiled an ambitious $64 million investment strategy today. The Commonwealth is set to transform 11 strategic sites through the inaugural round of the PA SITES (Pennsylvania Strategic Investments to Enhance Sites) program, signaling a significant commitment to economic development and community growth. This groundbreaking initiative demonstrates Pennsylvania's proactive approach to creating robust infrastructure and attracting new business opportunities. By strategically investing in key locations across the state, the Shapiro administration is laying the groundwork for future economic prosperity and job creation. The PA SITES program represents a forward-thinking approach to economic development, targeting critical sites that have the potential to become vibrant centers of innovation, commerce, and community revitalization. Each of the 11 selected projects promises to bring transformative potential to their respective regions, showcasing the Commonwealth's dedication to sustainable and strategic economic growth. MORE...

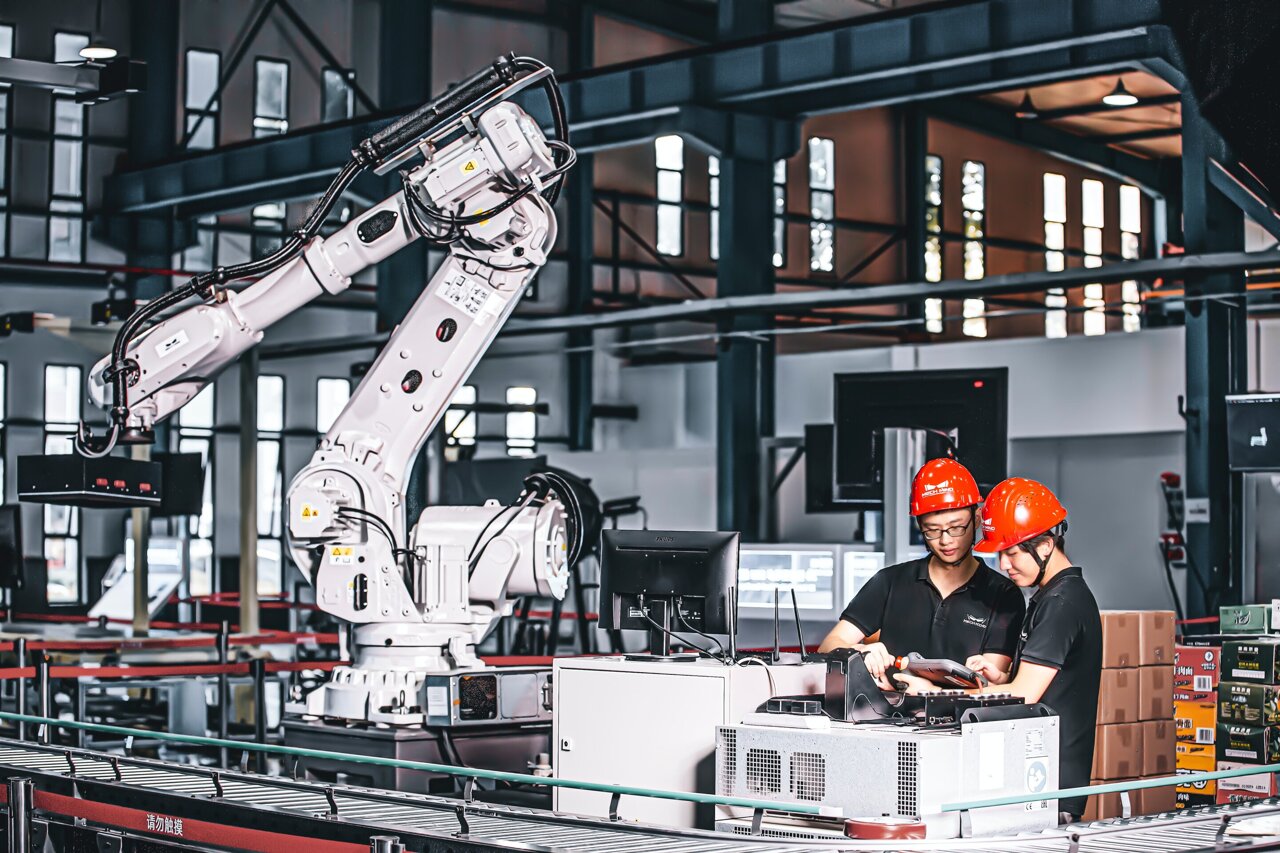

AI Revolution on the Factory Floor: Smart Tech Transforms Worker Safety and Product Precision

Manufacturing

2025-05-06 15:45:04

Beyond Text: The Expanding Frontiers of Artificial Intelligence While recent artificial intelligence breakthroughs have predominantly centered on text-based applications, the technology is rapidly evolving to demonstrate remarkable potential across diverse industries. Manufacturing and service sectors are now witnessing transformative AI innovations that promise to revolutionize traditional operational approaches. AI's expanding capabilities are no longer confined to language processing and generation. Instead, intelligent systems are increasingly being deployed to optimize complex processes, enhance productivity, and drive strategic decision-making. From predictive maintenance in factories to personalized customer service solutions, artificial intelligence is proving to be a versatile and powerful tool for technological advancement. As researchers and industry leaders continue to push the boundaries of what AI can achieve, we are witnessing an exciting era of technological transformation that extends far beyond mere text manipulation. The future of artificial intelligence is dynamic, multifaceted, and brimming with unprecedented opportunities for innovation across multiple domains. MORE...

Green Victory: How Giant Eagle Turned Waste Management into a Zero-Waste Revolution

Manufacturing

2025-05-06 15:40:42

A leading regional grocery chain is making significant strides toward its ambitious zero-waste sustainability mission, transforming environmental challenges into innovative opportunities by 2030. The company has been strategically implementing comprehensive waste reduction strategies across its operations, demonstrating a commitment that goes beyond traditional corporate sustainability pledges. By integrating cutting-edge recycling technologies, optimizing supply chain logistics, and reimagining product packaging, the grocer is setting a new standard for environmental responsibility in the retail food industry. Key initiatives include dramatically reducing food waste through advanced inventory management systems, partnering with local food banks to redistribute surplus produce, and developing comprehensive composting programs. These efforts not only minimize environmental impact but also create tangible economic benefits for local communities. Leadership has emphasized that their zero-waste goal is more than a corporate target—it's a holistic approach to reimagining how grocery businesses can contribute to a more sustainable future. By tracking and continuously improving waste management practices, the company is proving that environmental stewardship and business success can go hand in hand. As the 2030 deadline approaches, this regional grocer stands as a compelling example of how strategic planning, technological innovation, and genuine environmental commitment can drive meaningful change in the retail sector. MORE...

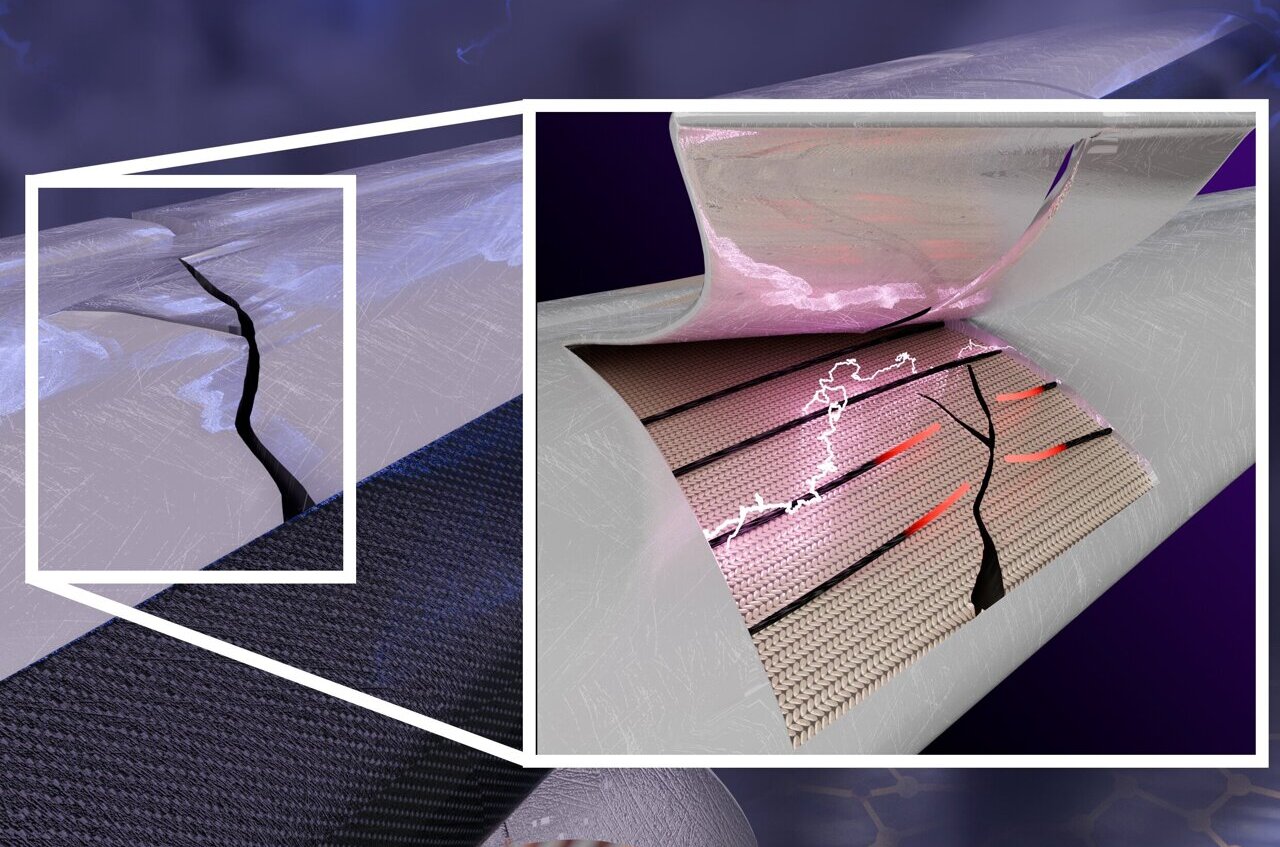

Revolutionary Nano-Tracking: How One Technique Could Transform Manufacturing Forever

Manufacturing

2025-05-06 15:09:03

Researchers at Skoltech have pioneered a groundbreaking approach to material monitoring that promises to revolutionize how we understand and analyze multifunctional materials. The collaborative effort between the Laboratory of Nanomaterials, Hierarchically Structured Materials Laboratory, and Materials Center has developed an innovative dual-stage monitoring technique that offers unprecedented insights into complex material structures. This cutting-edge method represents a significant leap forward in materials science, providing researchers with a more comprehensive and nuanced understanding of material behavior. By implementing a two-stage monitoring process, scientists can now detect and analyze intricate changes at both microscopic and macroscopic levels with remarkable precision. The novel technique demonstrates the power of interdisciplinary collaboration, showcasing how advanced research can push the boundaries of scientific understanding. Researchers are particularly excited about the potential applications across various fields, including advanced manufacturing, aerospace, and nanotechnology. While the full details of the technique remain under careful study, early indications suggest this approach could dramatically improve material performance assessment, quality control, and predictive maintenance strategies across multiple industries. MORE...

Pharma Pivot: Trump Moves to Revive US Drug Production in Bold Executive Sweep

Manufacturing

2025-05-06 14:18:49

In a bold move to revitalize domestic pharmaceutical production, President Donald Trump has signed a groundbreaking executive order aimed at transforming the pharmaceutical landscape. The new directive challenges the FDA to streamline regulatory processes for U.S. manufacturers while simultaneously creating significant barriers for international drug producers. The executive order represents a strategic effort to reduce America's dependence on foreign pharmaceutical supply chains and boost domestic manufacturing capabilities. By cutting through bureaucratic red tape, the administration hopes to incentivize pharmaceutical companies to bring production back to American soil, potentially creating jobs and enhancing national medical supply security. Under the new guidelines, domestic drug manufacturers will face fewer regulatory obstacles, making it easier and more attractive to establish and expand production facilities within the United States. Conversely, foreign pharmaceutical companies will encounter increasingly complex requirements, potentially discouraging international competition and protecting domestic industry interests. This initiative underscores the Trump administration's commitment to strengthening American manufacturing and reducing reliance on global supply chains, particularly in the critical healthcare sector. MORE...

Leadership Shift: Hyundai Taps New Chief to Steer Manufacturing Future

Manufacturing

2025-05-06 14:17:53

In a significant leadership transition, Mark Rader has stepped up to lead Hyundai Motor Manufacturing Alabama (HMMA), succeeding Chris Susock. This leadership change coincides with a milestone moment for the plant—its 20th anniversary. Rader's appointment marks a new chapter for the Montgomery-based manufacturing facility, which has been a cornerstone of Hyundai's manufacturing presence in the United States. As the plant celebrates two decades of automotive production, the leadership transition signals both continuity and forward momentum. With Rader taking the helm, HMMA looks forward to building on its strong legacy of quality manufacturing and continued growth in the automotive sector. The timing of this leadership change during the plant's anniversary year symbolizes a moment of reflection and renewed strategic vision. The transition represents an important moment for Hyundai's Alabama operations, promising continued innovation and excellence in automotive manufacturing. MORE...

Plastic Dreams, Global Realities: Why Mattel's CEO Sees No 'Made in USA' Toy Story

Manufacturing

2025-05-06 13:22:29

In a candid interview, Mattel's CEO Ynon Kreiz shed light on the company's manufacturing strategy, making it clear that large-scale toy production will not be shifting to American soil anytime soon. Despite growing calls for domestic manufacturing, Kreiz emphasized that the current global supply chain remains more economically viable for the toy giant. While reshoring manufacturing might seem appealing, Kreiz explained that the complex global network Mattel has developed offers significant cost advantages that would be challenging to replicate within the United States. The company continues to rely on international manufacturing partners, primarily in countries with lower production costs. However, consumers should brace themselves for potential price adjustments. Kreiz hinted that price increases are likely on the horizon, reflecting ongoing economic challenges, rising material costs, and supply chain complexities. These potential price hikes could impact the affordability of popular Mattel brands like Barbie, Hot Wheels, and Fisher-Price. The announcement underscores the ongoing tension between global manufacturing strategies and domestic production expectations. While many American consumers and politicians advocate for bringing manufacturing jobs back home, multinational corporations like Mattel continue to prioritize cost-effectiveness and established international supply chains. As the toy industry navigates these economic challenges, Mattel remains committed to delivering beloved products while managing the delicate balance between production costs and consumer pricing. MORE...

Smart Factories Revolution: How IoT is Transforming Manufacturing from the Ground Up

Manufacturing

2025-05-06 13:09:31

Revolutionizing Manufacturing: AI and IoT's Transformative Potential for Independent Software Vendors The manufacturing landscape is undergoing a remarkable digital transformation, presenting Independent Software Vendors (ISVs) with an unprecedented opportunity to drive innovation. At the intersection of artificial intelligence (AI) and the Internet of Things (IoT), factory automation is experiencing a groundbreaking evolution that promises to reshape industrial productivity and efficiency. For forward-thinking ISVs, this technological convergence represents a fertile ground for developing cutting-edge solutions. By leveraging AI's intelligent analytics and IoT's interconnected sensor networks, software developers can create sophisticated systems that optimize production processes, predict maintenance needs, and dramatically enhance operational performance. The potential for innovation is immense. Smart manufacturing platforms that integrate real-time data processing, machine learning algorithms, and seamless connectivity are no longer futuristic concepts but immediate opportunities. ISVs who can craft intelligent software solutions that bridge the gap between traditional manufacturing and digital intelligence will be at the forefront of this industrial revolution. From predictive maintenance to adaptive production scheduling, the AI and IoT ecosystem offers ISVs a chance to redefine manufacturing's technological boundaries. The time to innovate is now, and the possibilities are limited only by imagination and technical expertise. MORE...

Waymo's Massive Fleet Expansion: Doubling Down on Autonomous Driving

Manufacturing

2025-05-06 12:57:03

Once fully operational, the state-of-the-art manufacturing facility is poised to revolutionize vehicle production, with an impressive capacity to roll out tens of thousands of cutting-edge vehicles annually. This ambitious production target underscores the plant's advanced capabilities and strategic importance in meeting growing market demands. The facility represents a significant leap forward in automotive manufacturing, promising to deliver high-quality vehicles at an unprecedented scale. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238