Vinyl's Vital Signs: The Silent Crisis Threatening America's Record Pressing Industry

Manufacturing

2025-04-14 15:05:30

In the high-stakes world of vinyl record manufacturing, the looming threat of President Trump's tariffs sent shockwaves through the industry, creating a complex landscape of adaptation and survival. Larger vinyl pressing plants emerged as strategic survivors, while smaller manufacturers faced unprecedented challenges. The tariff storm initially threatened to disrupt the vinyl renaissance, a musical revival that had been steadily gaining momentum. Larger manufacturers like United Record Pressing in Nashville and Precision Record Pressing in Dallas quickly pivoted, developing innovative strategies to absorb and mitigate potential economic impacts. These industry giants leveraged their financial resources and operational flexibility to stockpile raw materials, negotiate alternative supply chains, and invest in domestic production capabilities. By anticipating potential disruptions, they transformed a potential crisis into an opportunity for strategic repositioning. Conversely, smaller record manufacturers found themselves navigating treacherous economic waters. Limited financial reserves and less robust supply chain networks made them particularly vulnerable to sudden price fluctuations and import restrictions. Many struggled to maintain competitive pricing while absorbing increased material costs. The vinyl resurgence, driven by audiophiles and music enthusiasts seeking authentic listening experiences, hung in delicate balance. Smaller manufacturers faced the stark choice of either absorbing additional costs or passing them onto consumers, risking potential market contraction. Ultimately, the vinyl pressing industry demonstrated remarkable resilience. Larger plants not only survived but often thrived, while smaller manufacturers implemented creative survival strategies, highlighting the sector's adaptability in the face of significant economic challenges. MORE...

Manufacturing Mayhem: Trump's Tariff Tangle Leaves Industry in Turmoil

Manufacturing

2025-04-14 14:56:27

In the wake of former President Trump's controversial trade policies, American coffee growers are experiencing significant challenges that extend far beyond traditional market dynamics. A prominent U.S. coffee producer recently highlighted the lasting impact of these policies, describing a troubling "unwillingness to work with American companies" that has emerged in the global trade landscape. The trade tensions created during the Trump administration have left deep scars in international business relationships, particularly for agricultural exporters like coffee growers. These policies, characterized by aggressive tariffs and confrontational diplomatic approaches, have seemingly deterred potential international partners from engaging with American businesses. For coffee producers, this means more than just economic uncertainty. It represents a fundamental shift in how global trade partners perceive and interact with U.S. agricultural enterprises. The ripple effects are tangible, with reduced market access and increased competition from international rivals who have not been similarly impacted by trade restrictions. As the industry continues to navigate these complex challenges, coffee growers are calling for more collaborative and strategic approaches to international trade—approaches that prioritize mutual economic benefits and long-term relationship building over short-term protectionist measures. MORE...

Smart Manufacturing Revolution: AI Security Fusion Unleashed by Genians and Ramen

Manufacturing

2025-04-14 14:47:00

In a groundbreaking collaboration that promises to revolutionize network security and connectivity, Genians and Ramen Inc. have joined forces to create an innovative AI-powered converged network and security platform. The strategic partnership, announced on April 14, 2025, brings together two industry leaders in Zero Trust Network Access (ZTNA) and Network-as-a-Service (NaaS) technologies. Genians, renowned for its cutting-edge Universal Zero Trust Network Access solutions, has partnered with Ramen Inc., a trailblazer in AI-driven network services, to address the complex connectivity challenges faced by modern enterprises. Their joint solution is meticulously designed to deliver seamless, secure connectivity across diverse environments—from traditional corporate office spaces to rugged industrial settings. This transformative partnership aims to break down the barriers between carpeted and uncarpeted environments, providing organizations with a unified, intelligent networking approach that adapts to the dynamic needs of today's digital landscape. By leveraging advanced AI technologies and robust zero-trust principles, the collaboration promises to set new standards in network security and operational efficiency. The converged platform represents a significant leap forward in how businesses can manage and secure their network infrastructure, offering unprecedented flexibility, reliability, and protection across various operational contexts. MORE...

Wall Street's Hottest Bet: Why Ken Griffin Is Doubling Down on Taiwan Semiconductor

Manufacturing

2025-04-14 13:08:18

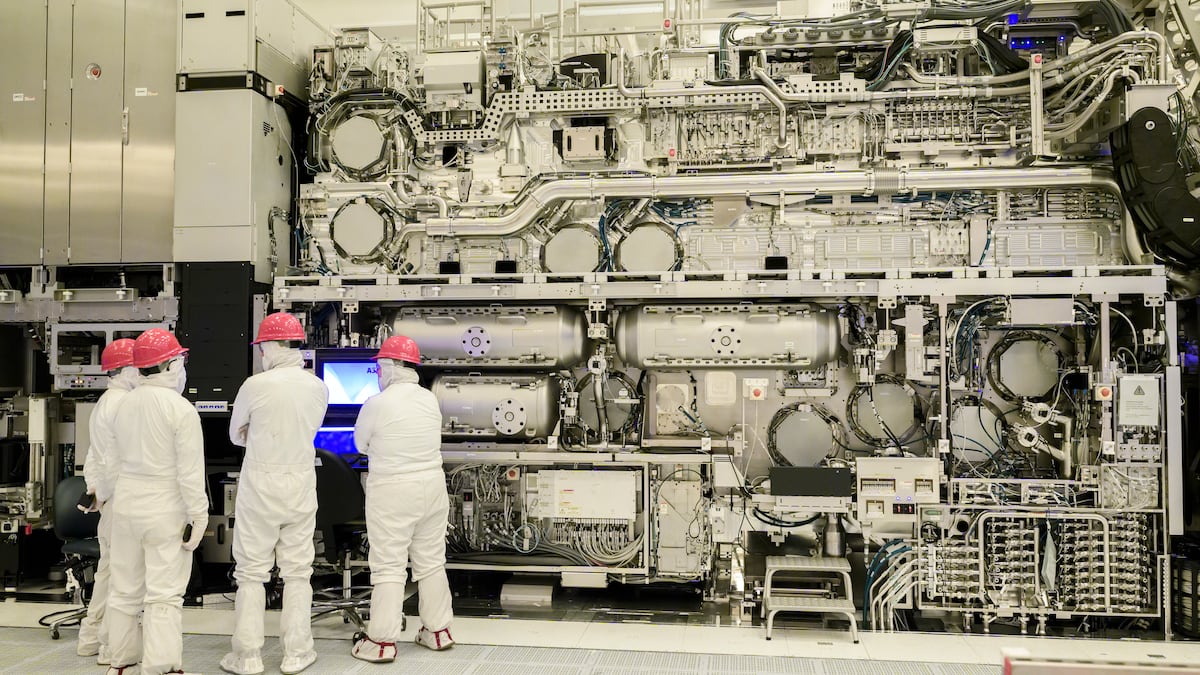

Taiwan Semiconductor: A Standout in Ken Griffin's Investment Strategy

In our recent exploration of Ken Griffin's top stock picks, Taiwan Semiconductor Manufacturing Company Limited (NYSE:TSM) emerges as a particularly intriguing investment. As one of the world's leading semiconductor manufacturers, TSM has captured the attention of sophisticated investors like Griffin, whose strategic portfolio choices often signal significant market potential.

The billionaire investor's interest in Taiwan Semiconductor is no coincidence. With the global tech landscape increasingly dependent on advanced semiconductor technology, TSM stands at the forefront of innovation and market demand. Analysts have been consistently bullish about the company's prospects, recognizing its critical role in supplying cutting-edge chips to major technology companies worldwide.

What sets Taiwan Semiconductor apart in Griffin's diverse portfolio is its robust market position, technological leadership, and potential for sustained growth. As the semiconductor industry continues to evolve, TSM's strategic investments in research and development make it a compelling choice for investors seeking exposure to the technology sector.

For those looking to understand the nuances of smart investment strategies, examining how top investors like Ken Griffin approach stocks such as Taiwan Semiconductor can provide valuable insights into potential market opportunities.

MORE...Chips on Home Soil: Nvidia's Bold Move to Bring AI Manufacturing Back to America

Manufacturing

2025-04-14 13:06:21

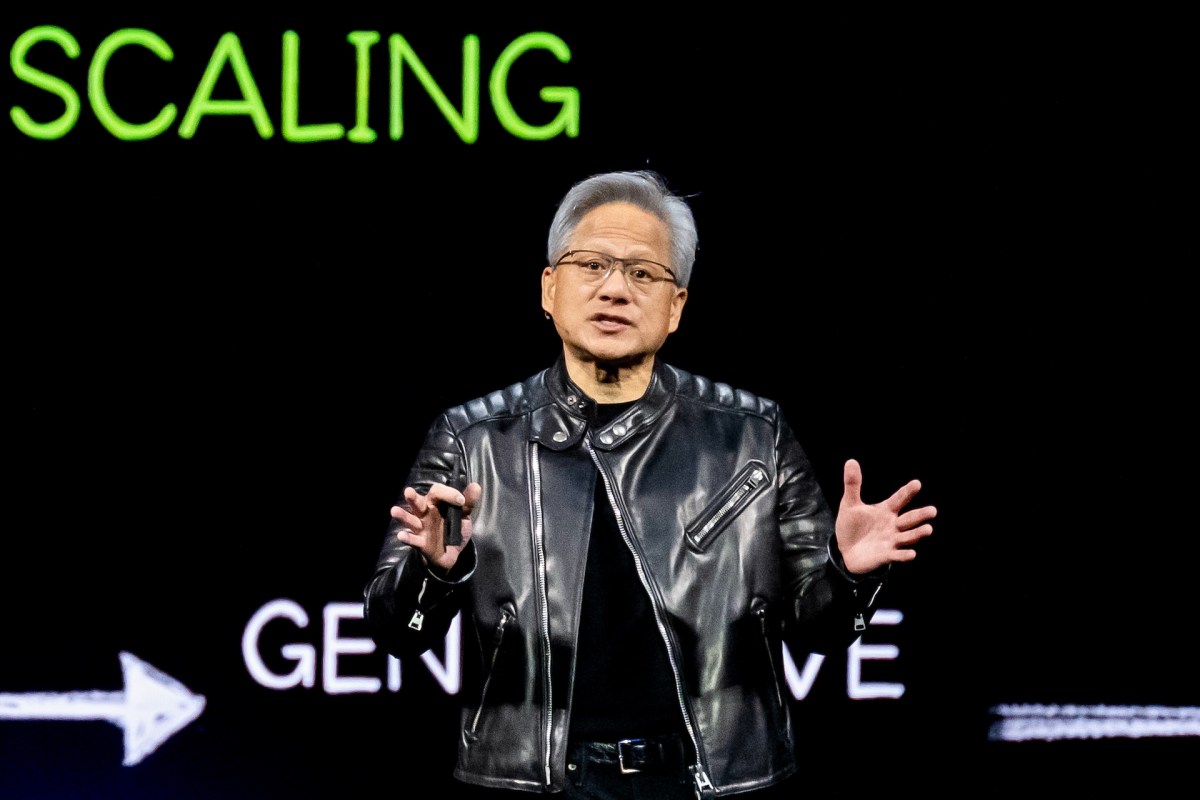

In a bold strategic move, Nvidia is expanding its manufacturing footprint across the United States, specifically targeting Arizona for a massive AI chip production initiative. The tech giant has committed to developing over one million square feet of cutting-edge manufacturing and testing facilities dedicated to creating advanced artificial intelligence semiconductor chips. This ambitious project represents a significant shift in Nvidia's production strategy, signaling a strong commitment to domestic manufacturing. By establishing this extensive manufacturing space in Arizona, the company aims to diversify its production capabilities and reduce reliance on international manufacturing centers. The investment underscores Nvidia's leadership in the AI technology landscape, demonstrating its ability to scale production and meet the growing global demand for high-performance computing chips. This expansion is not just about increasing manufacturing capacity, but also about positioning the United States as a critical hub for advanced semiconductor technology. As the demand for AI-powered technologies continues to surge across industries, Nvidia's strategic move in Arizona could potentially reshape the semiconductor manufacturing ecosystem and reinforce the country's technological competitiveness on the global stage. MORE...

Manufacturing's Resurgence: How Small Business Funding Is Rebuilding America's Industrial Backbone

Manufacturing

2025-04-14 13:00:12

The Resurgence of American Manufacturing: A New Industrial Renaissance For decades, American manufacturing has weathered a challenging landscape of decline and uncertainty. However, a remarkable transformation is now underway, signaling a promising revival of the nation's industrial prowess. The U.S. Small Business Administration is playing a pivotal role in this renaissance, championing innovative strategies to reinvigorate domestic production. This resurgence isn't just a fleeting trend, but a strategic shift that promises to reshape the economic landscape. By supporting small businesses, investing in advanced technologies, and creating robust manufacturing ecosystems, the United States is reclaiming its position as a global industrial leader. From cutting-edge technology sectors to traditional manufacturing domains, American companies are demonstrating remarkable resilience and adaptability. The tide is turning, bringing renewed hope and opportunity to workers, entrepreneurs, and communities across the nation. As we stand on the cusp of this manufacturing renaissance, the future looks increasingly bright for American industry. MORE...

Earnings Spotlight: Simpson Manufacturing Set to Unveil Q1 2025 Financial Performance

Manufacturing

2025-04-14 13:00:00

Simpson Manufacturing Set to Unveil First Quarter 2025 Financial Results PLEASANTON, Calif. - Leading structural engineering solutions provider Simpson Manufacturing Co., Inc. (NYSE:SSD) is preparing to share its financial performance for the first quarter of 2025. The company has scheduled its comprehensive financial report for Monday, April 28, 2025, to be released at 4:15 p.m. Eastern Time. Following the financial report, company executives Michael Olosky, President and Chief Executive Officer, and Matt Dunn, Chief Financial Officer and Treasurer, will host an investor conference call at 5:00 p.m. Eastern Time. Investors and interested parties can tune in to the live broadcast through the company's Investor Relations website at ir.simpsonmfg.com. The upcoming financial disclosure offers stakeholders an opportunity to gain insights into Simpson Manufacturing's strategic performance and market positioning during the first quarter of 2025. MORE...

Silicon Valley Giant NVIDIA Breaks Ground: First US-Crafted AI Supercomputer Signals Domestic Tech Renaissance

Manufacturing

2025-04-14 12:59:52

NVIDIA is pioneering a groundbreaking initiative to establish domestic manufacturing capabilities for its cutting-edge AI supercomputers. In an unprecedented move, the tech giant is collaborating closely with its manufacturing partners to develop and construct state-of-the-art facilities dedicated to producing NVIDIA's advanced AI computing systems entirely within the United States. This strategic effort marks a significant milestone in the company's commitment to reshoring high-tech manufacturing and strengthening the domestic technology infrastructure. By localizing the production of these sophisticated AI supercomputers, NVIDIA aims to enhance supply chain resilience, reduce international dependencies, and accelerate innovation in artificial intelligence technology. The initiative not only represents a major technological achievement but also signals NVIDIA's dedication to supporting American manufacturing and technological leadership in the global AI landscape. As the demand for powerful AI computing solutions continues to surge, this domestic production strategy positions the company at the forefront of technological innovation and national technological capabilities. MORE...

Breaking: Additive Manufacturing Stabilization Techniques Revolutionize Industrial Processes

Manufacturing

2025-04-14 12:51:00

Pushing the Boundaries of Additive Manufacturing: Innovation Meets Digital Transformation At the cutting-edge RAPID + TCT 2025 conference in Detroit, Hexagon's Jeff Robertson shared compelling insights into the evolving landscape of additive manufacturing. The industry is experiencing a remarkable transformation, driven by groundbreaking alloy developments and an accelerating digital revolution. Robertson highlighted how emerging alloy technologies are breaking traditional manufacturing constraints, enabling engineers and designers to create increasingly complex and high-performance components. Simultaneously, the push toward comprehensive digitization is streamlining production processes, enhancing precision, and unlocking new possibilities in manufacturing. The convergence of advanced materials and digital technologies is not just incremental—it represents a fundamental shift in how we conceive and execute manufacturing strategies. By embracing these innovations, industries can achieve unprecedented levels of efficiency, customization, and performance. As additive manufacturing continues to mature, the synergy between material science and digital technologies promises to redefine manufacturing paradigms, offering exciting prospects for engineers, designers, and manufacturers alike. MORE...

iPhone's India Surge: Apple Scales Production by 60%, Targets Massive $22B Export Milestone

Manufacturing

2025-04-14 12:31:42

Apple is rapidly transforming its manufacturing landscape in India, signaling a strategic pivot that could reshape the global smartphone production ecosystem. The tech giant is set to dramatically boost iPhone production in the country, with projections indicating a substantial increase in local manufacturing output. Industry experts reveal that Apple is targeting a remarkable 20% surge in iPhone production within India, a move that underscores the company's commitment to diversifying its manufacturing base beyond traditional strongholds like China. This ambitious expansion is not just about numbers, but represents a calculated strategy to mitigate supply chain risks and tap into the massive Indian market. Foxconn, Apple's primary manufacturing partner, is playing a pivotal role in this transformation. The company's facilities in Chennai and other Indian locations are being rapidly scaled up to meet the increased production targets. This expansion is expected to create thousands of local jobs and potentially position India as a critical hub in Apple's global manufacturing network. The shift comes at a crucial time, as global tech companies seek to reduce their dependence on Chinese manufacturing. India, with its large workforce, growing tech ecosystem, and supportive government policies, has emerged as an attractive alternative. The Indian government's production-linked incentive schemes have further sweetened the deal, making local manufacturing increasingly attractive for international brands. For Apple, this move is more than just a strategic realignment. It represents a significant opportunity to deepen its footprint in one of the world's fastest-growing smartphone markets. With India's young, tech-savvy population and increasing digital consumption, the potential for growth is immense. As Apple accelerates its Indian manufacturing journey, the global tech industry is watching closely. This could be a watershed moment that redefines global electronics production and cements India's position as a major player in the international manufacturing landscape. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238