Bridging Gaps: How UT's Innovative Collaboration Could Solve America's Defense Manufacturing Crisis

Manufacturing

2025-03-20 13:30:05

The University of Texas is revolutionizing manufacturing education through its innovative METAL bootcamp, a cutting-edge program designed to cultivate the next generation of casting and forging experts. This intensive training initiative bridges the gap between academic knowledge and real-world industrial skills, empowering students to become tomorrow's manufacturing innovators. At the heart of the bootcamp, participants dive deep into the intricate world of metal manufacturing, gaining hands-on experience with advanced techniques and state-of-the-art technologies. Students learn critical skills in casting and forging processes, transforming raw theoretical knowledge into practical expertise that is immediately valuable in today's competitive industrial landscape. The program goes beyond traditional classroom learning, offering immersive workshops and collaborative projects that simulate real-world manufacturing challenges. By combining technical instruction with practical application, the METAL bootcamp ensures that graduates are not just educated, but truly prepared to drive innovation in the manufacturing sector. Industry leaders have praised the initiative, recognizing its potential to address the growing skills gap in advanced manufacturing. Participants emerge from the program with a comprehensive understanding of metalworking techniques, cutting-edge technologies, and the problem-solving skills necessary to excel in modern industrial environments. As manufacturing continues to evolve, UT's METAL bootcamp stands at the forefront of educational innovation, transforming passionate students into the skilled professionals who will shape the future of industrial production. MORE...

Solar Power Revolution: Mission Solar Energy Ramps Up Production with Cutting-Edge Cell Manufacturing

Manufacturing

2025-03-20 13:15:00

Mission Solar Energy Bolsters U.S. Solar Manufacturing with Strategic Investment In a bold move to reinforce America's renewable energy infrastructure, Mission Solar Energy is set to make a significant leap forward in domestic solar panel production. The company is positioning itself as a key player in strengthening the nation's solar supply chain through a major strategic investment in local manufacturing capabilities. This groundbreaking initiative underscores the company's commitment to advancing domestic clean energy production and reducing reliance on international solar component imports. By expanding its manufacturing footprint, Mission Solar Energy aims to create jobs, drive technological innovation, and support the growing demand for American-made solar solutions. The investment signals a pivotal moment for the U.S. solar industry, highlighting the potential for domestic manufacturers to play a crucial role in the country's transition to sustainable energy. Mission Solar Energy's strategic approach demonstrates a forward-thinking commitment to building a more resilient and self-sufficient renewable energy ecosystem. As the solar market continues to expand, this bold investment promises to position Mission Solar Energy at the forefront of America's clean energy revolution, offering high-quality, locally produced solar technology to meet the nation's growing green energy needs. MORE...

AI Revolution: LimitlessCNC Secures $4.1M to Reshape Future of Manufacturing

Manufacturing

2025-03-20 12:17:39

In a groundbreaking move for advanced manufacturing technology, LimitlessCNC has stepped out of stealth mode with an impressive $4.1 million seed funding round. The AI-powered manufacturing startup secured investments from prominent venture capital firms Grove Ventures and Meron Capital, signaling strong industry confidence in their innovative approach. The company is pioneering a transformative solution by developing sophisticated AI agents designed to revolutionize CNC (computer numerical control) machining processes. By leveraging artificial intelligence, LimitlessCNC aims to automate and streamline manufacturing workflows, potentially increasing efficiency and precision in computer-controlled machining operations. This strategic funding will enable LimitlessCNC to accelerate its technology development, refine its AI algorithms, and bring cutting-edge automation capabilities to the manufacturing sector. The startup's vision represents a significant leap forward in integrating artificial intelligence with traditional manufacturing techniques. MORE...

Chips and Transformation: Nvidia's Massive US Manufacturing Gambit Unveiled

Manufacturing

2025-03-20 12:12:16

In response to escalating trade tensions, companies are strategically repositioning their supply chains to navigate the uncertain landscape created by potential tariff impositions. The ongoing trade uncertainties, primarily driven by the Trump administration's aggressive trade policies, have prompted businesses to seek more resilient and flexible sourcing strategies. This proactive approach is designed to shield companies from potential economic disruptions and minimize the financial impact of potential trade barriers. By diversifying their supply networks and exploring alternative manufacturing locations, businesses are building a robust defense against the unpredictable trade environment. The strategic realignment reflects a broader corporate strategy of risk mitigation, demonstrating how companies are adapting to the complex geopolitical and economic challenges of the current global trade landscape. As tensions continue to evolve, businesses remain committed to maintaining operational flexibility and protecting their economic interests. MORE...

Strategic Manufacturing: How Amsted Automotive Shields Automakers from Tariff Turbulence

Manufacturing

2025-03-20 12:04:00

Amsted Automotive Drives Innovation in Automotive Manufacturing Efficiency In the competitive landscape of automotive manufacturing, Amsted Automotive stands out as a global leader, strategically optimizing production processes to deliver exceptional value to automakers worldwide. By leveraging cutting-edge manufacturing capabilities and a comprehensive global network, the company has mastered the art of maximizing operational efficiencies while simultaneously reducing production costs. The company's approach goes beyond traditional manufacturing strategies, focusing on intelligent design, advanced technologies, and streamlined production techniques. Through strategic investments in state-of-the-art facilities and a deep understanding of automotive industry dynamics, Amsted Automotive helps manufacturers transform their production models, creating more competitive and cost-effective solutions. By combining technical expertise with innovative manufacturing strategies, Amsted Automotive continues to set new standards in automotive component production, empowering automakers to achieve greater performance and economic sustainability in an increasingly complex global market. MORE...

Driving the Future: How GM and NVIDIA Are Revolutionizing Automotive Technology

Manufacturing

2025-03-20 10:48:02

Driving the Future: GM's Vision of Automotive Innovation In a compelling exploration of technological advancement, David Richardson, Senior Vice President of Software and Services Engineering at General Motors, offers an inspiring glimpse into the company's cutting-edge approach to automotive innovation. Richardson's insights reveal how GM is not just adapting to technological changes, but actively shaping the future of mobility. With a passion for pushing technological boundaries, Richardson highlights GM's commitment to reimagining transportation through sophisticated software engineering and forward-thinking service design. The company is strategically positioning itself at the intersection of automotive manufacturing and digital innovation, creating seamless experiences that transform how we think about transportation. By integrating advanced software solutions with revolutionary automotive design, GM is demonstrating that the future of mobility is about more than just vehicles—it's about creating intelligent, connected experiences that enhance how people move, interact, and explore the world around them. MORE...

AI's Next Frontier: VIAVI Unveils Cutting-Edge Testing Arsenal for Infrastructure Revolution

Manufacturing

2025-03-20 10:30:00

VIAVI Solutions Unveils Cutting-Edge AI Infrastructure Testing Technologies VIAVI Solutions Inc. (NASDAQ: VIAV) is set to revolutionize AI infrastructure development with its latest breakthrough testing solutions. The company is preparing to showcase a comprehensive suite of advanced technologies designed to address the complex challenges of modern artificial intelligence infrastructure testing. At the forefront of technological innovation, VIAVI is positioning itself as a critical partner for organizations seeking robust and reliable AI infrastructure validation. Their new testing solutions promise to deliver unprecedented insights and performance metrics, enabling technology leaders to optimize AI system development with greater precision and confidence. The announcement highlights VIAVI's commitment to pushing the boundaries of technological testing, providing engineers and researchers with state-of-the-art tools that can effectively diagnose, validate, and enhance AI infrastructure performance. By introducing these sophisticated testing capabilities, VIAVI is empowering businesses to accelerate their AI development processes and ensure the highest standards of technological reliability. Industry experts anticipate that VIAVI's latest offerings will play a pivotal role in supporting the rapidly evolving landscape of artificial intelligence infrastructure, addressing critical testing requirements across various technological domains. MORE...

Chip Revolution: Nvidia's Massive $4B Bet on American Manufacturing

Manufacturing

2025-03-20 10:23:12

Nvidia, the tech giant renowned for its cutting-edge graphics and AI technologies, is set to make a groundbreaking move in the semiconductor industry. The company is reportedly preparing to invest substantially in domestic semiconductor production and electronic component manufacturing across the United States. This strategic initiative signals Nvidia's commitment to strengthening the nation's technological infrastructure and reducing dependence on international supply chains. By localizing production, the company aims to enhance supply chain resilience, accelerate innovation, and potentially create numerous high-tech manufacturing jobs. The planned investment comes at a critical time when the United States is actively seeking to bolster its domestic semiconductor capabilities. With global supply chain disruptions and increasing geopolitical tensions, Nvidia's move could be a significant step towards establishing a more robust and self-sufficient electronic components ecosystem. While specific details of the investment are yet to be fully disclosed, industry experts view this development as a potential game-changer for the US technology manufacturing landscape. The investment is expected to not only benefit Nvidia but also contribute to the broader national strategy of technological self-sufficiency. MORE...

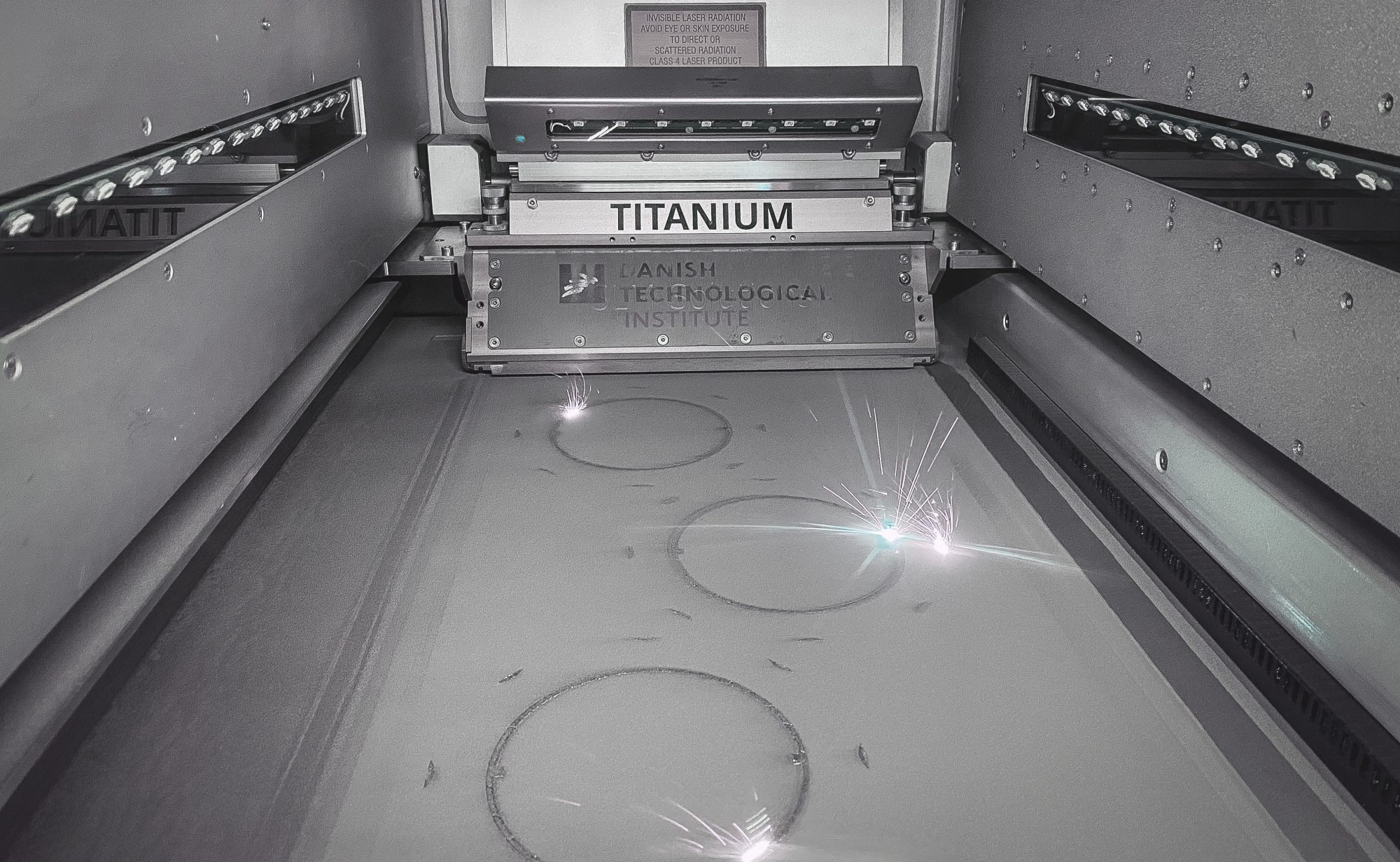

3D Printing Revolution: How Next-Gen Tech is Transforming Manufacturing Certification

Manufacturing

2025-03-20 10:21:13

Pioneering the Future of Additive Manufacturing: DILAPRO's Revolutionary Approach In the rapidly evolving world of advanced manufacturing, researchers are breaking new ground in additive manufacturing technologies. The DILAPRO project stands at the forefront of this innovation, offering a transformative approach to enhancing efficiency and streamlining certification processes. At its core, DILAPRO represents a breakthrough in addressing critical challenges within additive manufacturing. The project focuses on developing sophisticated methodologies that dramatically improve production workflows and quality assurance mechanisms. By integrating cutting-edge data analysis and precision engineering techniques, DILAPRO enables manufacturers to achieve unprecedented levels of reliability and performance. Key innovations include: • Advanced process monitoring systems • Intelligent data integration techniques • Comprehensive certification protocols • Real-time quality control mechanisms The project's unique approach allows manufacturers to overcome traditional limitations in additive manufacturing, reducing production times and minimizing potential errors. By creating more robust and transparent manufacturing processes, DILAPRO is setting new industry standards for precision and efficiency. Researchers involved in the project emphasize that DILAPRO is not just about technological advancement, but about reimagining the entire manufacturing ecosystem. The innovative framework promises to accelerate adoption of additive manufacturing across multiple industries, from aerospace and automotive to medical device production. As manufacturing continues to evolve, DILAPRO represents a critical step towards more intelligent, responsive, and reliable production technologies. MORE...

Manufacturing Crossroads: How Morden-Winkler Employers Are Reshaping Workforce Strategy Under Tariff Pressure

Manufacturing

2025-03-20 10:00:00

Nestled in southern Manitoba, the Morden-Winkler region has emerged as a vibrant manufacturing powerhouse, celebrated for its remarkable innovation and entrepreneurial spirit. This dynamic area, located approximately 80 kilometers southwest of Winnipeg, boasts a diverse industrial landscape that ranges from precision cabinet making to sophisticated tractor cab manufacturing. Despite its economic strength and diverse production capabilities, the region now faces a significant challenge: the ongoing trade tensions between Canada and the United States. The recent tariff disputes, sparked by U.S. President Donald Trump's trade policies, are casting a shadow over the local manufacturing ecosystem. While Trump temporarily paused the 25 percent levy on certain Canadian goods until April 2, the underlying economic uncertainty continues to create ripples of concern among local manufacturers. Canada's retaliatory tariffs further complicate the already delicate trade relationship, potentially impacting the thousands of workers employed in this thriving industrial corridor. The Morden-Winkler area stands as a testament to Canadian manufacturing resilience, demonstrating adaptability in the face of complex international trade dynamics. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238