Innovation Hub: Amsino Unveils Cutting-Edge Manufacturing Complex in Massachusetts

Manufacturing

2025-04-15 19:41:22

Franklin, Mass.— Amsino International is making a bold strategic move by significantly expanding its U.S. operations with the launch of a cutting-edge medical device manufacturing and research facility in Franklin, Massachusetts. This ambitious expansion is set to dramatically increase the company's manufacturing capacity and research capabilities, effectively doubling its existing footprint in the region. The new state-of-the-art facility represents a major investment in innovation and local economic development, signaling Amsino International's commitment to strengthening its presence in the competitive medical device industry. By establishing this advanced manufacturing and research center, the company is positioning itself to accelerate product development, enhance technological capabilities, and meet growing market demands. Located in the heart of Franklin, the facility promises to not only boost Amsino's operational efficiency but also potentially create new job opportunities for local professionals in the medical technology sector. This strategic expansion underscores the company's vision for growth and its dedication to pushing the boundaries of medical device technology. MORE...

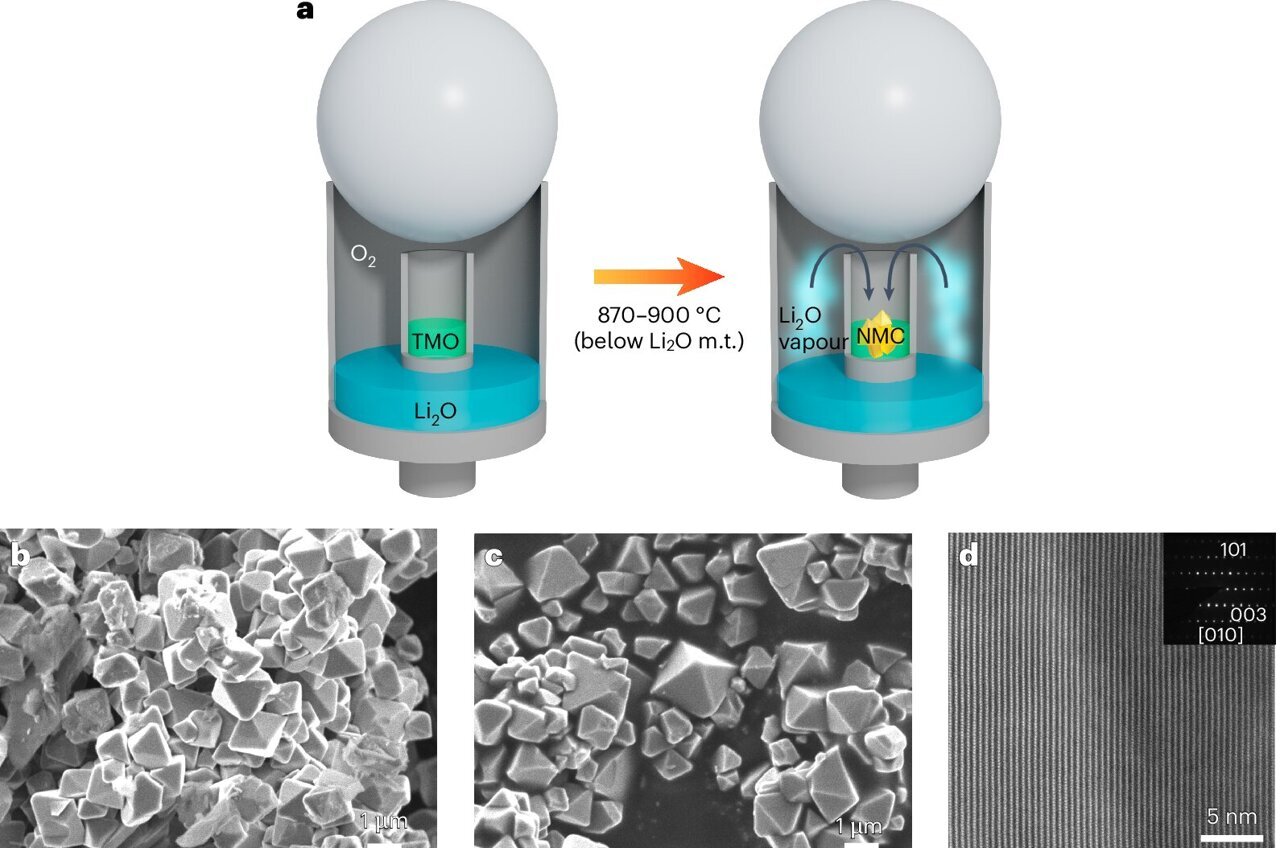

Battery Revolution: How Lithium Oxide Sublimation Could Slash Production Costs

Manufacturing

2025-04-15 19:10:34

A breakthrough in battery technology is on the horizon, thanks to an unexpected hero: a humble lithium salt that could revolutionize how we power our devices. Researchers have uncovered exciting new pathways for creating battery materials that are not only more cost-effective but also promise significantly extended lifespans. This groundbreaking discovery centers on a common lithium salt that scientists have found can dramatically transform the manufacturing process of battery components. By reimagining traditional approaches, researchers are paving the way for more affordable and durable energy storage solutions that could impact everything from smartphones to electric vehicles. The potential implications are enormous. Imagine smartphones that last days on a single charge, electric cars with ranges that stretch far beyond current limitations, and renewable energy systems that can store power more efficiently and economically. This innovative approach could be the key to unlocking next-generation energy storage technologies that have long been just out of reach. While the full details of the research are still emerging, early indications suggest this could be a game-changing development in the world of battery technology. As the global demand for more powerful, longer-lasting, and more sustainable energy solutions continues to grow, discoveries like these offer a glimpse into a more efficient technological future. MORE...

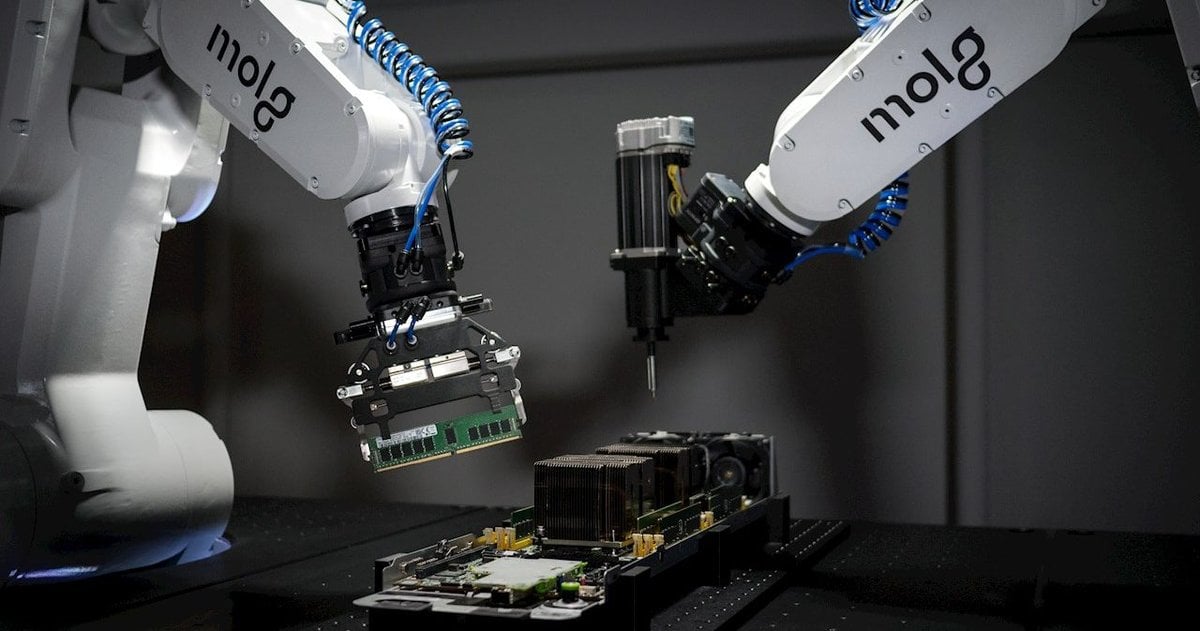

Musk's DOGE Layoffs: The Hidden Labor Story Behind American Manufacturing Revival

Manufacturing

2025-04-15 19:00:00

In a bold proclamation that has sparked both intrigue and skepticism, Elon Musk has suggested that thousands of recently laid-off government workers could find new opportunities staffing his expanding factory operations. However, the tech mogul's vision is met with a competing narrative from industry experts who argue that automation and robotics are more likely to fill these industrial roles. Musk's ambitious statement comes at a time of significant workforce disruption, with many government employees facing unexpected job losses. His proposal presents an alternative path for these workers, suggesting they could transition into manufacturing roles within his various enterprises, including Tesla and SpaceX. Contrary to Musk's optimistic outlook, technological analysts point to the increasing trend of robotic automation in modern factories. They contend that advanced robots are becoming more sophisticated and cost-effective, potentially rendering human labor less critical in high-precision manufacturing environments. The debate highlights the ongoing tension between human workforce potential and technological innovation, raising critical questions about employment in an increasingly automated world. As industries continue to evolve, the future of work remains a complex and dynamic landscape. MORE...

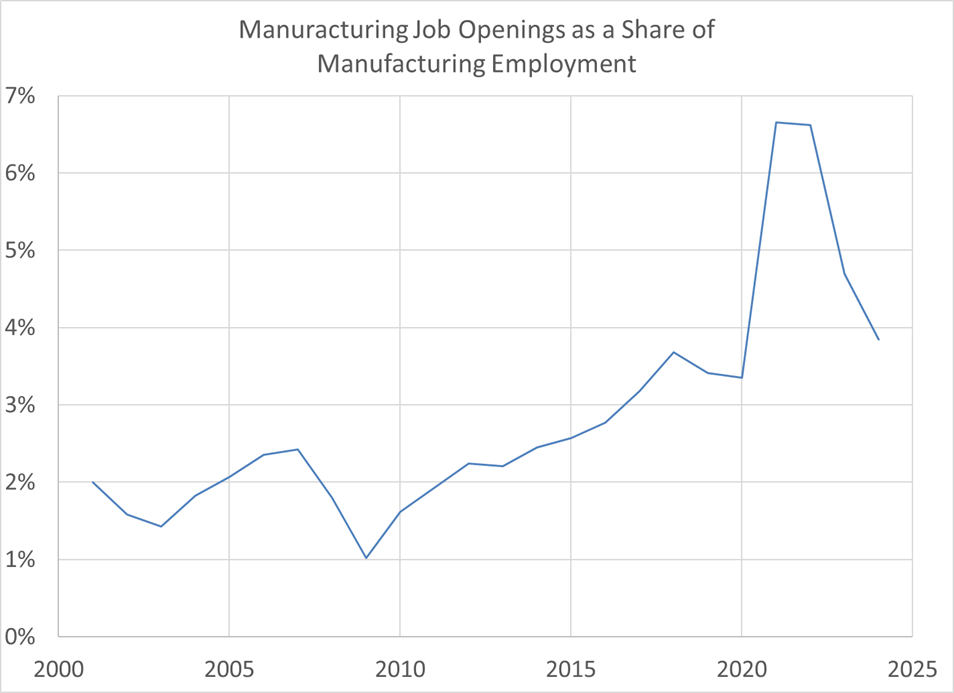

Manufacturing's Hidden Surge: Why 10x Job Growth Might Be Closer Than You Think

Manufacturing

2025-04-15 18:54:09

Navigating the Complex World of Data Analysis: Precision Matters Data analysis is a delicate art that demands meticulous attention and critical thinking. While the stakes might not be as immediately life-threatening as a surgical misstep, the potential for far-reaching consequences remains significant. A single misinterpreted data point or flawed statistical inference can dramatically skew public understanding and derail important policy discussions. The landscape of data interpretation is fraught with potential pitfalls. One misread graph, an overlooked statistical anomaly, or a hasty conclusion can ripple through academic, political, and social conversations, potentially misleading decision-makers and the public alike. The responsibility of data analysts extends far beyond mere number-crunching; it's about crafting a narrative that is both accurate and illuminating. In an era of information overload, the ability to dissect and understand complex datasets has never been more crucial. Careful analysis isn't just a technical skill—it's a critical safeguard against misinformation and a pathway to genuine insight. MORE...

Revolutionizing Medical Care: 3D Systems Brings Facial Implants Directly to Hospitals

Manufacturing

2025-04-15 18:19:00

In a groundbreaking advancement for medical technology, 3D Systems has revealed that its cutting-edge point-of-care additive manufacturing solution has successfully enabled the design and production of the first Medical Device Regulation (MDR)-compliant 3D-printed PEEK facial implant. This milestone represents a significant leap forward in personalized medical device manufacturing, showcasing the potential of advanced 3D printing techniques to revolutionize reconstructive surgery. The innovative use of PEEK (polyether ether ketone), a high-performance polymer known for its biocompatibility and mechanical strength, demonstrates the precision and capabilities of 3D Systems' advanced manufacturing technology. By achieving MDR compliance, this breakthrough ensures that the facial implant meets the most rigorous medical standards, providing surgeons and patients with a safe, customizable, and technologically sophisticated solution for complex facial reconstructions. This development highlights the transformative power of additive manufacturing in healthcare, offering unprecedented opportunities for creating patient-specific medical devices that can dramatically improve surgical outcomes and patient quality of life. MORE...

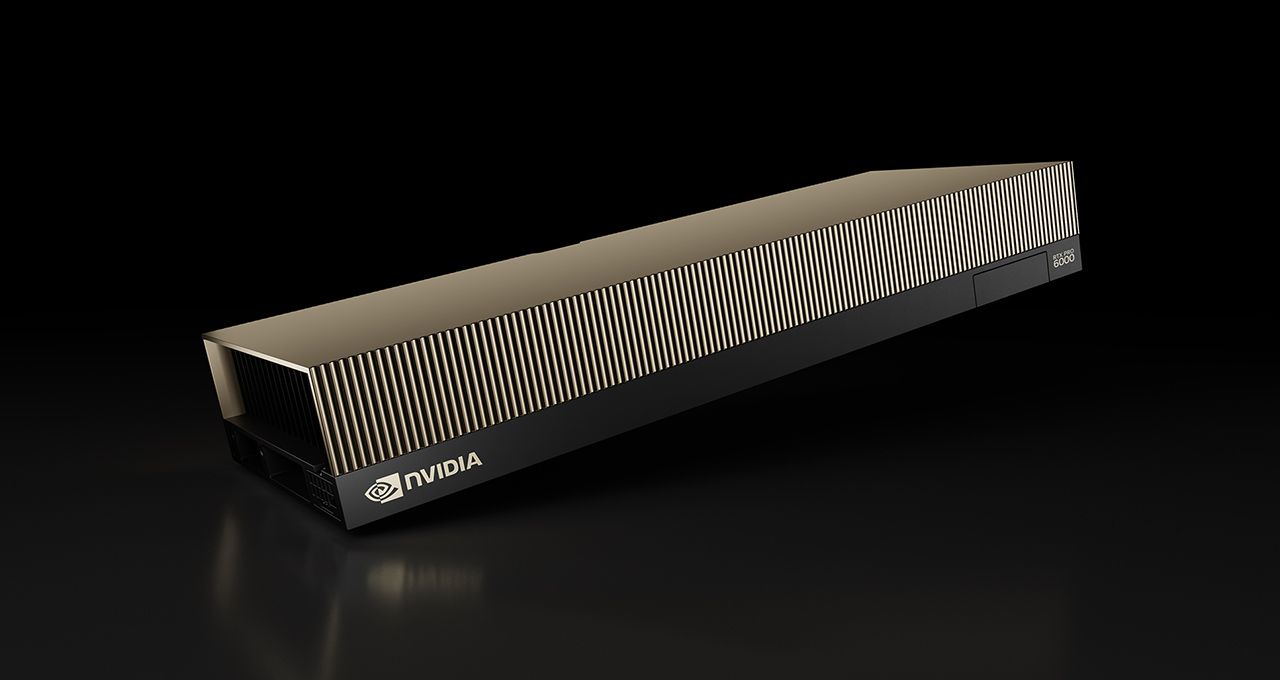

AI Revolution: Nvidia Unveils Massive $500B Infrastructure Plan to Supercharge American Tech Dominance

Manufacturing

2025-04-15 18:18:52

Nvidia Unveils Massive $500 Billion AI Infrastructure Investment Across the United States In a groundbreaking move that signals the tech industry's commitment to artificial intelligence, Nvidia has revealed an ambitious plan to invest a staggering $500 billion in cutting-edge AI infrastructure throughout the United States. This monumental investment promises to revolutionize technological capabilities and solidify the country's position at the forefront of AI innovation. The comprehensive strategy aims to develop state-of-the-art data centers, advanced computing facilities, and robust AI research networks that will serve as the backbone of next-generation technological advancements. By making such a substantial commitment, Nvidia is not just investing in hardware, but in the future of technological progress and economic growth. Industry experts view this initiative as a game-changing moment for AI development, potentially accelerating breakthroughs in fields ranging from healthcare and scientific research to autonomous technologies and machine learning. The massive infrastructure investment is expected to create numerous high-tech jobs and position the United States as a global leader in artificial intelligence capabilities. As the tech landscape continues to evolve rapidly, Nvidia's bold strategy demonstrates the company's vision and confidence in the transformative potential of AI technologies. This unprecedented investment is set to reshape the technological ecosystem and drive innovation to unprecedented heights. MORE...

Sukup Manufacturing Expands Horizons: New Iowa State Research Park Office Signals Growth Strategy

Manufacturing

2025-04-15 18:04:16

Sukup Manufacturing, a leading Sheffield, Iowa-based manufacturer of grain storage and drying equipment, is expanding its innovative capabilities with a new research and development facility at the Iowa State University Research Park in Ames. The strategic move will provide the company with additional space to accelerate its technological advancements and drive future growth in agricultural equipment design. By establishing this new R&D office, Sukup is demonstrating its commitment to innovation and its strong ties to Iowa's agricultural technology sector. The expanded research space will enable the company to develop cutting-edge solutions for farmers, leveraging the proximity to Iowa State University's engineering and agricultural expertise. This expansion represents an exciting next step for Sukup, positioning the company to continue its tradition of engineering excellence and meet the evolving needs of modern agricultural professionals. MORE...

Made in America: Can Apple Break Free from Chinese Manufacturing?

Manufacturing

2025-04-15 17:23:58

The Looming Impact of US Tariffs: A Tech Industry Transformation As trade tensions continue to simmer, US tariffs are poised to send shockwaves through the consumer electronics and telecommunications landscape. Among the most affected players, Apple emerges as a potential frontrunner in this complex economic chess game, facing mounting pressure to reimagine its global manufacturing strategy. The potential shift towards domestic production is not just a policy challenge but a strategic pivot that could reshape the entire tech manufacturing ecosystem. While the implementation timeline remains uncertain, the implications are crystal clear: companies will need to adapt, innovate, and potentially restructure their global supply chains. Apple, with its intricate global manufacturing network, stands at a critical crossroads. The tech giant must now carefully balance cost-effectiveness, supply chain resilience, and geopolitical considerations. But the million-dollar question remains: Is a comprehensive US-based production model truly feasible in today's interconnected global economy? As the industry watches and waits, one thing becomes increasingly evident—the landscape of consumer electronics manufacturing is on the brink of a significant transformation. MORE...

Honda's Bold Move: Supercharging American Manufacturing Landscape

Manufacturing

2025-04-15 15:49:38

In a bold strategic move, the automaker has set an ambitious goal to dramatically localize its production, aiming to manufacture 90% of its vehicles sold in the United States within the country's borders. This initiative underscores a strong commitment to domestic manufacturing, potentially reshaping the automotive landscape and supporting American jobs. By prioritizing U.S.-based production, the company signals a significant shift towards strengthening its domestic manufacturing capabilities. This approach not only promises to boost local employment but also demonstrates a strategic investment in the nation's industrial infrastructure. The plan reflects a growing trend of companies seeking to reduce international supply chain dependencies and create more resilient production networks. The automaker's vision goes beyond mere numbers, representing a comprehensive strategy to enhance local economic growth and maintain competitive advantage in an increasingly complex global market. As the automotive industry continues to evolve, this commitment to domestic manufacturing could serve as a powerful model for other manufacturers looking to invest in American production capabilities. MORE...

Honda's Bold Move: Revving Up US Manufacturing with Major Production Shift

Manufacturing

2025-04-15 15:24:45

Honda is set to accelerate its manufacturing capabilities in the United States, with ambitious plans to ramp up production by as much as 30% in the coming two to three years, according to a recent report by the Nikkei business newspaper. This strategic expansion signals the automaker's commitment to strengthening its presence in the North American automotive market and responding to growing consumer demand. The planned production boost demonstrates Honda's confidence in the U.S. market and its ability to adapt to changing economic landscapes. By increasing manufacturing output, the company aims to enhance its competitive edge, potentially creating new job opportunities and supporting local economic growth. While specific details about the production expansion were not immediately disclosed, industry analysts suggest this move could involve retooling existing facilities or potentially investing in new manufacturing infrastructure across the United States. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238