Bridging Gaps: How UT's Innovative Collaboration Could Solve America's Defense Manufacturing Crisis

Manufacturing

2025-03-20 13:30:05Content

The University of Texas is revolutionizing manufacturing education through its innovative METAL bootcamp, a cutting-edge program designed to cultivate the next generation of casting and forging experts. This intensive training initiative bridges the gap between academic knowledge and real-world industrial skills, empowering students to become tomorrow's manufacturing innovators.

At the heart of the bootcamp, participants dive deep into the intricate world of metal manufacturing, gaining hands-on experience with advanced techniques and state-of-the-art technologies. Students learn critical skills in casting and forging processes, transforming raw theoretical knowledge into practical expertise that is immediately valuable in today's competitive industrial landscape.

The program goes beyond traditional classroom learning, offering immersive workshops and collaborative projects that simulate real-world manufacturing challenges. By combining technical instruction with practical application, the METAL bootcamp ensures that graduates are not just educated, but truly prepared to drive innovation in the manufacturing sector.

Industry leaders have praised the initiative, recognizing its potential to address the growing skills gap in advanced manufacturing. Participants emerge from the program with a comprehensive understanding of metalworking techniques, cutting-edge technologies, and the problem-solving skills necessary to excel in modern industrial environments.

As manufacturing continues to evolve, UT's METAL bootcamp stands at the forefront of educational innovation, transforming passionate students into the skilled professionals who will shape the future of industrial production.

Forging the Future: How UT's METAL Bootcamp is Revolutionizing Manufacturing Innovation

In the rapidly evolving landscape of advanced manufacturing, educational institutions are increasingly becoming crucibles of technological transformation. The University of Tennessee's groundbreaking METAL bootcamp emerges as a beacon of hope, bridging the critical gap between academic knowledge and industrial innovation, preparing a new generation of engineers and technologists to reshape the manufacturing ecosystem.Unleashing Potential: Where Cutting-Edge Technology Meets Hands-On Learning

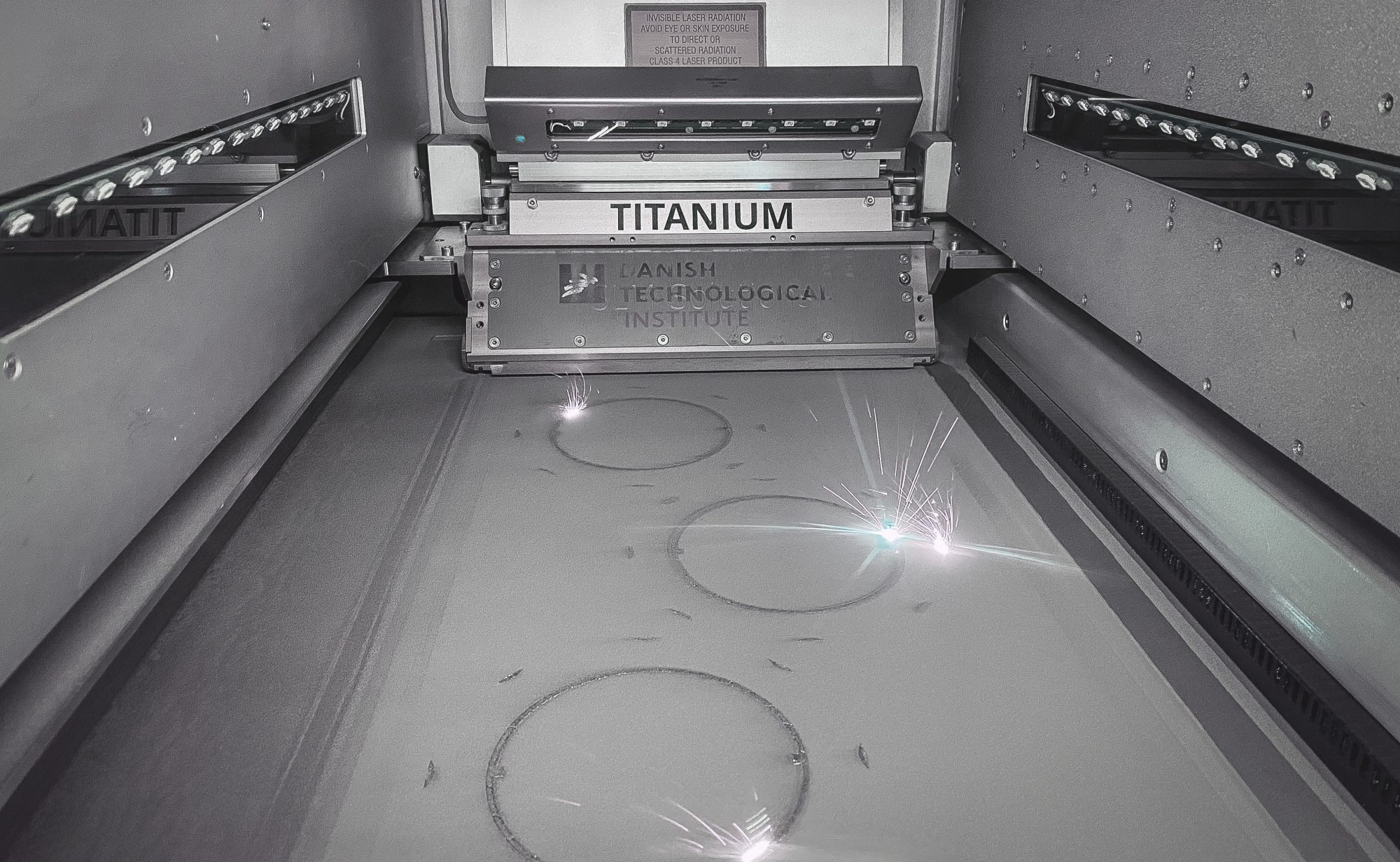

The Technological Frontier of Casting and Forging

The METAL bootcamp represents more than a traditional training program; it's a comprehensive immersion into the intricate world of advanced manufacturing techniques. Participants are thrust into an environment where theoretical concepts seamlessly blend with practical applications, creating a transformative learning experience that challenges conventional educational paradigms. Participants engage with state-of-the-art equipment and methodologies that push the boundaries of traditional casting and forging techniques. Through intensive workshops and collaborative projects, students develop a nuanced understanding of material science, metallurgical principles, and advanced manufacturing processes that are critical in today's competitive industrial landscape.Curriculum Design: Precision Engineering Meets Strategic Innovation

The bootcamp's curriculum is meticulously crafted to address the complex demands of modern manufacturing. By integrating advanced computational modeling, real-world simulation technologies, and hands-on practical training, participants are equipped with a holistic skill set that transcends traditional engineering education. Instructors, who are themselves industry veterans and research pioneers, bring a wealth of practical experience to the classroom. They guide participants through complex problem-solving scenarios, encouraging innovative thinking and fostering a culture of continuous technological adaptation. The program goes beyond technical skills, emphasizing critical thinking, collaborative problem-solving, and adaptive learning strategies.Industry Collaboration: Bridging Academic Expertise and Industrial Needs

Strategic partnerships with leading manufacturing corporations transform the bootcamp into a dynamic ecosystem of innovation. These collaborations ensure that the curriculum remains aligned with emerging industry trends, providing participants with insights into real-world challenges and opportunities. Corporate mentors actively engage with participants, offering guidance, sharing industry insights, and potentially creating pathways for future employment. This symbiotic relationship between academic institutions and industrial leaders creates a powerful platform for knowledge exchange and technological advancement.Technological Empowerment and Career Transformation

Participants emerge from the METAL bootcamp not just as skilled technicians, but as potential industry disruptors. The program's comprehensive approach equips them with a sophisticated understanding of advanced manufacturing technologies, positioning them at the forefront of technological innovation. The bootcamp's impact extends far beyond individual skill development. By nurturing a new generation of technologically adept professionals, the University of Tennessee is contributing to the broader narrative of industrial innovation, helping to maintain the United States' competitive edge in global manufacturing.Sustainable Manufacturing: A Vision for the Future

Beyond technical skills, the METAL bootcamp emphasizes the critical importance of sustainable manufacturing practices. Participants learn to integrate environmental consciousness with technological innovation, understanding that future manufacturing must balance technological advancement with ecological responsibility. Through specialized modules focusing on resource efficiency, waste reduction, and sustainable design principles, the bootcamp prepares participants to be not just engineers, but responsible technological stewards who can drive meaningful change in the manufacturing sector.RELATED NEWS

Manufacturing

Chip Giant TSMC Shatters Expectations: A Blockbuster Year Unfolds in 2024

2025-03-24 12:23:08

Manufacturing

Breaking: How CloudPaths and NetSuite Are Revolutionizing Manufacturing Cost Management

2025-03-25 22:05:56

Manufacturing

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/shawmedia/KX3AQ6GG4VF7DC55H5BVTVREOU.png)

Tech Titan's Massive Footprint: How a 1,000-Acre Data Center Could Transform Yorkville's Industrial Landscape

2025-03-24 11:00:00