Chip Crisis Solved? Thermo Fisher Unveils Game-Changing Manufacturing Breakthrough

Manufacturing

2025-03-26 11:10:00

Revolutionizing Semiconductor Manufacturing: A Cutting-Edge Productivity Solution In the fast-paced world of semiconductor production, innovation is key to staying competitive. Our groundbreaking system represents a quantum leap in manufacturing technology, meticulously engineered to transform the semiconductor production landscape. By seamlessly integrating advanced technologies, this intelligent solution delivers a powerful trifecta of benefits: dramatically enhanced productivity, significant yield improvements, and substantial reductions in operating costs. Designed with precision and forward-thinking engineering, the system addresses the most critical challenges faced by semiconductor manufacturers today. It eliminates inefficiencies, streamlines complex production processes, and provides manufacturers with an unprecedented competitive edge in a demanding global market. From optimizing workflow to minimizing resource waste, this innovative solution is set to redefine the standards of semiconductor manufacturing excellence. MORE...

Frontline Heroes: How CGT Professionals Are Reshaping Healthcare's Future

Manufacturing

2025-03-26 10:20:25

In the rapidly evolving landscape of cell and gene therapy manufacturing, the battle for top talent has never been more intense. As breakthrough technologies continue to transform medical treatments, companies are discovering that attracting and retaining skilled professionals requires more than competitive salaries—it demands a strategic approach to workforce development. The key to success lies in robust training and mentorship programs that not only draw exceptional talent but also nurture their potential. With the cell and gene therapy sector experiencing unprecedented growth, organizations must invest heavily in creating comprehensive learning environments that empower employees to excel. Effective mentorship goes beyond traditional training models. It involves creating collaborative cultures where experienced professionals can guide emerging talent, sharing critical insights and practical knowledge that textbooks cannot capture. By establishing strong mentorship frameworks, companies can accelerate skill development, boost employee engagement, and build a resilient workforce capable of driving innovation. Moreover, companies that prioritize continuous learning and professional development will gain a significant competitive advantage. In an industry where technological advancements happen at lightning speed, the ability to quickly adapt and upskill becomes a critical differentiator. The message is clear: investing in human capital is no longer optional—it's essential for success in the dynamic world of cell and gene therapy manufacturing. MORE...

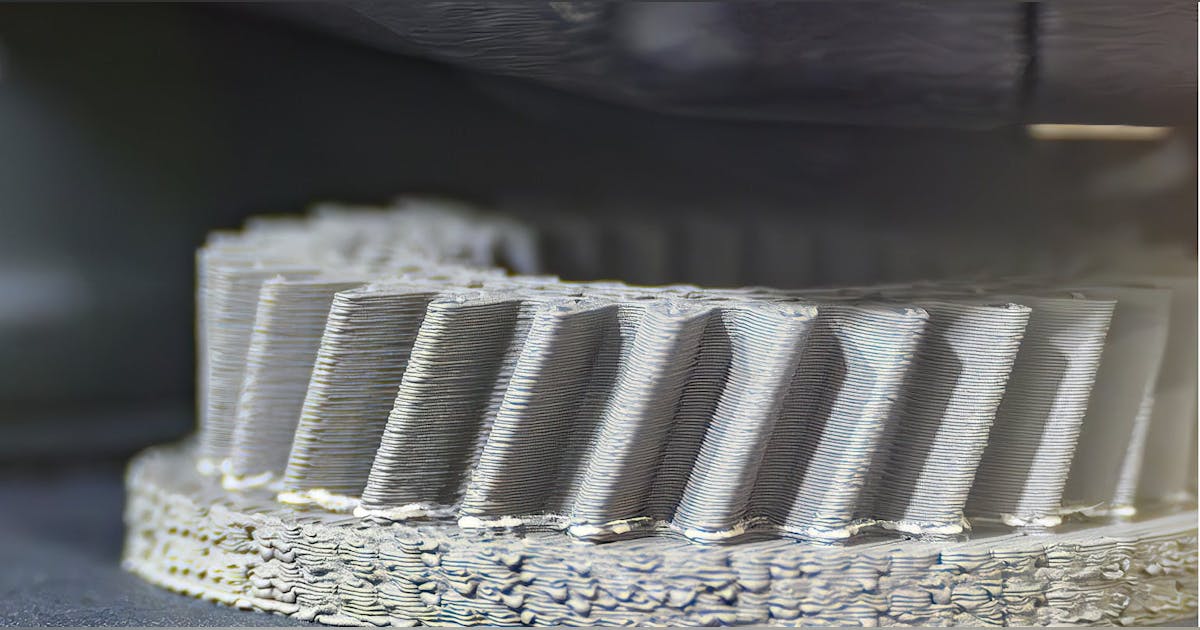

Forging Transatlantic Defense Tech: US and UK Unite in $1.1M Additive Manufacturing Breakthrough

Manufacturing

2025-03-26 09:44:26

Nestled in the heart of Youngstown, Ohio, America Makes stands as a pioneering force in the world of additive manufacturing. As the United States' premier national accelerator for 3D printing technology, the organization is operated by the National Center for Defense Manufacturing and Machining (NCDMM). With a commitment to innovation and technological advancement, America Makes continues to push the boundaries of manufacturing excellence, driving forward cutting-edge solutions that have the potential to transform industries across the nation. MORE...

Revolutionizing Manufacturing: The Ceramic 3D Printing Pioneers Reshaping Industry Frontiers

Manufacturing

2025-03-26 09:18:20

Revolutionizing Manufacturing: The Pioneers of Ceramic 3D Printing

In the cutting-edge world of advanced manufacturing, ceramic additive manufacturing is emerging as a game-changing technology that is transforming how we design, create, and innovate with technical ceramics. These innovative companies are pushing the boundaries of what's possible, delivering unprecedented precision, complexity, and performance across multiple industries.

Leading Innovators Reshaping Ceramic Manufacturing

At the forefront of this technological revolution are companies that are reimagining ceramic production through advanced 3D printing techniques. These trailblazers are not just creating components; they're engineering solutions that were previously impossible with traditional manufacturing methods.

Key Advantages of Ceramic Additive Manufacturing

- Unprecedented design flexibility

- Reduced material waste

- Complex geometries impossible with conventional methods

- Faster prototyping and production cycles

From aerospace and medical devices to electronics and industrial applications, ceramic 3D printing is opening new frontiers of innovation. Companies are developing specialized techniques that enable the creation of intricate ceramic parts with exceptional precision, strength, and thermal resistance.

The Future of Technical Ceramics

As research continues and technologies advance, we can expect even more groundbreaking developments in ceramic additive manufacturing. These innovations promise to revolutionize industries by providing lighter, stronger, and more sophisticated ceramic components that were once thought impossible to produce.

The journey of ceramic 3D printing is just beginning, and the potential seems limitless. Companies investing in this technology are not just manufacturing components—they're crafting the future of materials engineering.

MORE...Arsenal Evolution: How America's Defense Industry Is Reshaping Modern Warfare

Manufacturing

2025-03-26 08:00:00

In the high-stakes arena of Great Power Competition, Mach Industries emerges as a critical voice advocating for the revitalization of American manufacturing's military capabilities. The company's strategic insights highlight the urgent need to transform domestic industrial infrastructure to meet the complex challenges of modern geopolitical tensions. As global rivals continue to advance their technological and military prowess, Mach Industries emphasizes that the United States must rapidly enhance its manufacturing ecosystem. The key lies not just in producing more military equipment, but in developing more agile, innovative, and technologically sophisticated production systems. The company's experts argue that strengthening domestic manufacturing is more than an economic imperative—it's a national security necessity. By investing in advanced manufacturing technologies, streamlining supply chains, and fostering closer collaboration between defense contractors and industrial manufacturers, the U.S. can significantly boost its military readiness and strategic deterrence. Mach Industries proposes a multi-pronged approach: modernizing existing facilities, incentivizing cutting-edge research and development, and creating flexible manufacturing platforms that can quickly adapt to emerging defense requirements. This strategy aims to reduce dependency on international suppliers and ensure the United States maintains a competitive edge in an increasingly complex global landscape. The message is clear: American manufacturing must evolve, innovate, and accelerate to effectively respond to the challenges of Great Power Competition. By reimagining industrial capabilities, the nation can strengthen its military output and preserve its strategic advantages. MORE...

Oral GLP-1 Drugs: The Next Frontier in Weight Loss and Diabetes Management

Manufacturing

2025-03-26 06:35:00

As the pharmaceutical landscape shifts towards innovative diabetes and weight management treatments, the industry faces a critical challenge: ensuring robust supply chains for emerging oral GLP-1 medications. Learning from recent injectable GLP-1 shortages, pharmaceutical experts are sounding the alarm about potential supply constraints that could impact patient access to these groundbreaking therapies. The lessons from previous manufacturing disruptions have highlighted the importance of proactive supply chain management. With oral GLP-1 medications poised to revolutionize treatment options, manufacturers and healthcare providers must work collaboratively to anticipate and mitigate potential bottlenecks. Industry leaders emphasize that securing a consistent and reliable supply will be paramount. The stakes are high, as these medications represent a significant breakthrough in managing metabolic health, offering patients more convenient and accessible treatment alternatives to traditional injectable medications. Stakeholders are now focusing on developing resilient manufacturing strategies, diversifying production capabilities, and implementing advanced supply chain technologies to prevent potential shortages. The goal is to ensure that these promising oral medications can reach patients efficiently and consistently, learning from the challenges experienced with previous GLP-1 treatment options. MORE...

Manufacturing's Comeback: How Trump's Trade Strategy Could Spark an Industrial Renaissance

Manufacturing

2025-03-26 06:22:54

Discover the Tema American Reshoring ETF: A Strategic Investment in Domestic Manufacturing Revival The Tema American Reshoring ETF offers investors a targeted approach to capitalizing on the growing trend of companies bringing manufacturing back to the United States. This innovative fund provides a unique opportunity to invest directly in businesses that are at the forefront of the reshoring movement, potentially delivering more substantial returns compared to broader market strategies. By focusing specifically on companies actively participating in and benefiting from reshoring initiatives, this ETF presents a compelling investment vehicle for those looking to support and profit from the revitalization of American manufacturing. Investors interested in exploring this exciting opportunity can find more detailed information about the RSHO ETF through comprehensive research and financial resources. MORE...

Made in America: Sherrill Manufacturing Marks Two Decades of Resilience and Innovation

Manufacturing

2025-03-26 03:00:00

In a celebration of resilience and American manufacturing, Sherrill Manufacturing marked its remarkable 20-year milestone with enthusiasm and pride. On Tuesday, March 25, company leaders Greg Owens and Matt Roberts—CEO and president, respectively—commemorated two decades of success by cutting a ceremonial cake at their manufacturing facility. The event not only highlighted the company's longevity but also symbolized its commitment to domestic production and industrial innovation. Standing side by side, Owens and Roberts reflected on the journey that has transformed Sherrill Manufacturing from a startup to a respected name in American manufacturing. Their cake-cutting ceremony was more than just a festive moment; it represented 20 years of hard work, strategic vision, and unwavering dedication to maintaining a strong manufacturing presence in the United States. The milestone serves as a testament to the company's ability to thrive in a challenging industrial landscape. MORE...

Tech Showdown: Nano Dimension Faces Ultimatum in High-Stakes Merger Battle

Manufacturing

2025-03-26 00:00:00

In a significant legal development, a court has decisively ruled against the additive manufacturing group, finding them in breach of their merger agreement with Desktop Metal. The ruling mandates that Nano Dimension must proceed with the originally planned takeover, setting a firm deadline of March 31 for completing the transaction. This judicial intervention comes after months of uncertainty and potential complications surrounding the proposed merger. The court's clear directive leaves little room for further delay or negotiation, effectively compelling Nano Dimension to honor its original commitment to Desktop Metal. The ruling underscores the legal system's role in enforcing corporate agreements and provides a definitive path forward for both companies in this high-stakes additive manufacturing landscape. With the March 31 deadline now firmly established, stakeholders will be closely watching how Nano Dimension moves to implement the court-mandated merger. MORE...

Breaking: Revolutionary Tech Brings Life-Saving Treatments Directly to Your Doorstep

Manufacturing

2025-03-26 00:00:00

Revolutionizing Point-of-Care Manufacturing: Cutting-Edge Trends Transforming Healthcare

The point-of-care (POC) manufacturing landscape is undergoing a remarkable transformation, driven by groundbreaking innovations that are reshaping how medical diagnostics and devices are developed and deployed. From advanced automation technologies to revolutionary material science, the industry is experiencing a dynamic shift that promises to enhance scalability, improve product quality, and seamlessly integrate clinical workflows.

Key Trends Driving POC Manufacturing Forward

- Smart Automation: Cutting-edge robotic systems and AI-powered manufacturing processes are streamlining production, reducing human error, and accelerating development cycles.

- Advanced Materials: Breakthrough material innovations are enabling more precise, durable, and cost-effective point-of-care devices with unprecedented performance capabilities.

- Clinical Integration: Next-generation manufacturing techniques are creating seamless connections between production processes and real-world medical applications.

As these transformative trends continue to evolve, the future of point-of-care manufacturing looks increasingly sophisticated, efficient, and patient-centric.

MORE...- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238