Breaking: How Next-Gen Tech is Revolutionizing Medical Device Production

Manufacturing

2025-04-17 11:30:00

The landscape of medical manufacturing is undergoing a revolutionary transformation, driven by cutting-edge technologies that are reshaping how medical implants and prosthetics are designed and produced. Additive manufacturing, coupled with artificial intelligence, is ushering in a new era of precision, customization, and innovation in medical device production. Gone are the days of one-size-fits-all medical solutions. Today, advanced 3D printing techniques and intelligent AI algorithms are enabling unprecedented levels of personalization in medical implants. Surgeons and medical engineers can now create bespoke prosthetics and implants that are precisely tailored to individual patient anatomies, dramatically improving treatment outcomes and patient comfort. Artificial intelligence plays a crucial role in this technological revolution. Machine learning algorithms analyze vast amounts of medical data, helping to optimize design parameters, predict potential performance issues, and create increasingly sophisticated medical devices. From intricate joint replacements to complex cranial implants, AI-driven design is pushing the boundaries of what's possible in medical manufacturing. The convergence of additive manufacturing and AI is not just changing production methods—it's fundamentally reimagining patient care. By enabling faster prototyping, reducing production costs, and creating more personalized medical solutions, these technologies are opening new frontiers in medical treatment and patient recovery. MORE...

Industrial Giant Breaks Ground: New Manufacturing Hub Transforms Leland's Economic Landscape

Manufacturing

2025-04-17 11:00:00

Brunswick County is set to take a significant step forward in economic development after the Board of Commissioners approved the sale of approximately 22 acres within the county-owned Leland Innovation Park to US MgO, a promising American manufacturing company. The strategic land transaction marks an exciting milestone for Brunswick County, signaling potential job creation and industrial growth in the region. By selecting the Leland Innovation Park as its new home, US MgO demonstrates confidence in the area's business-friendly environment and economic potential. This development represents a notable expansion of the county's efforts to attract innovative manufacturers and create opportunities for local economic advancement. The sale of the park's acreage to US MgO is expected to bring new employment prospects and contribute to the region's economic vitality. MORE...

Forget Tariffs: J&J's Bold Tax Strategy to Revive American Manufacturing

Manufacturing

2025-04-17 10:44:26

In a candid discussion with investors, Johnson & Johnson's CEO has highlighted a strategic approach to bolstering U.S. manufacturing that goes beyond traditional trade barriers. Rather than relying on tariffs, the company's leadership advocates for a more nuanced solution: strategic tax policy. The executive argues that meaningful growth in domestic manufacturing requires a comprehensive tax framework that incentivizes companies to invest in American production capabilities. By creating a more attractive financial landscape, the United States can encourage businesses to bring manufacturing jobs back home and strengthen the nation's industrial infrastructure. This approach represents a sophisticated alternative to protectionist trade measures. Tax incentives can provide a more sustainable and long-term strategy for revitalizing domestic manufacturing, offering companies tangible financial benefits for investing in U.S. production facilities and workforce development. Johnson & Johnson's perspective underscores the importance of smart economic policy in driving industrial growth. By focusing on tax strategies that support manufacturers, the company believes the United States can create a more competitive and robust domestic manufacturing ecosystem. MORE...

Trade Tensions: How Tariffs Are Reshaping U.S. Manufacturing's Blueprint

Manufacturing

2025-04-17 10:10:08

In a bold strategic move, the United States has unveiled a new tariff policy designed to revitalize domestic manufacturing and spark a renaissance of industrial investment within its borders. This innovative approach aims to fundamentally reshape the economic landscape by incentivizing companies to bring production back home and reduce reliance on international supply chains. The comprehensive tariff regime represents a significant shift in economic policy, targeting the core of global manufacturing dynamics. By creating financial advantages for businesses that choose to reshore their production facilities, the U.S. government is sending a clear message: investing in American manufacturing is not just patriotic, but economically smart. These carefully crafted trade measures are intended to strengthen the nation's industrial base, create domestic jobs, and build greater economic resilience. Companies are now facing a compelling economic argument to reconsider their global manufacturing strategies, with potential tax benefits and reduced import costs serving as powerful motivators for bringing production back to American soil. The policy signals a strategic commitment to rebuilding domestic manufacturing capabilities, positioning the United States as a more competitive player in the global economic arena while simultaneously addressing long-standing concerns about economic vulnerability and supply chain fragility. MORE...

Manufacturing Mirage: Trump's Job Creation Quest Hits Roadblocks and Rising Costs

Manufacturing

2025-04-17 10:00:00

President Trump's ambitious manufacturing reshoring initiative is sending ripples of uncertainty through American industries, challenging businesses with rising costs and complex economic implications. While the administration aims to bring tens of thousands of manufacturing jobs back to U.S. soil, companies are grappling with the potential consequences of this dramatic economic shift. Economists are increasingly skeptical about the feasibility and long-term sustainability of this aggressive manufacturing repatriation strategy. The push to relocate production from overseas threatens to disrupt carefully constructed global supply chains and potentially increase consumer prices across multiple sectors. Many industries are finding themselves at a crossroads, weighing the patriotic appeal of domestic manufacturing against the economic realities of global competition. The potential benefits of job creation are being carefully balanced against the increased operational costs and potential reduction in international competitiveness. As businesses navigate this complex landscape, the true impact of the administration's manufacturing strategy remains uncertain. Companies must now make critical decisions about their production models, weighing national economic goals against their own financial sustainability and global market positioning. MORE...

Breaking: Global Clinical Trial Supplies Market Set to Revolutionize Drug Development by 2029

Manufacturing

2025-04-17 09:40:00

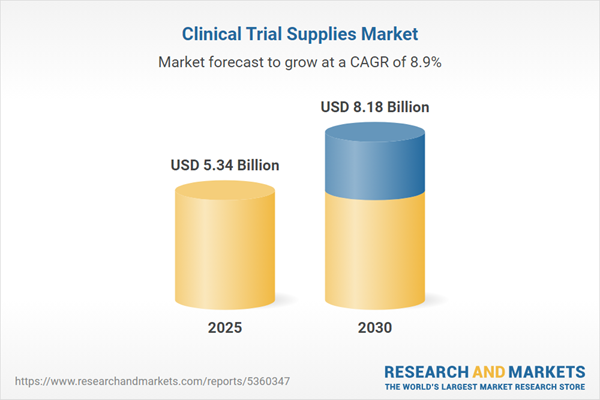

Clinical Trial Supply Chain: Driving Innovation and Efficiency in Pharmaceutical Research

The clinical trial supply chain is experiencing a transformative era, powered by a convergence of dynamic factors that are reshaping the pharmaceutical research landscape. Unprecedented growth is being fueled by three critical drivers: escalating trial complexity, the rapid expansion of personalized medicine, and increasingly stringent regulatory requirements.

Emerging Trends Revolutionizing Clinical Trial Logistics

The industry is witnessing a paradigm shift towards more sophisticated and technology-driven approaches. Key trends include:

- Decentralized clinical trials that offer greater patient flexibility

- Advanced logistics solutions with enhanced tracking and management capabilities

- Digital transformation leveraging cutting-edge technologies like Internet of Things (IoT) and Artificial Intelligence (AI)

Market Dynamics and Strategic Segments

Current market dynamics highlight the prominence of Logistics & Distribution Services and Phase III trials, with North America emerging as the dominant market leader. Pharmaceutical companies and Contract Research Organizations (CROs) are strategically deploying innovative technologies to optimize supply chain efficiency and streamline research processes.

Future Outlook

As the clinical trial supply chain continues to evolve, stakeholders are poised to embrace technological innovations that promise enhanced precision, reduced costs, and accelerated research timelines.

MORE...Manufacturing Giants Unveil Bold Regulatory Roadmap for Trump Era

Manufacturing

2025-04-17 09:05:31

In a bold move to streamline business regulations, the National Association of Manufacturers (NAM) has submitted a comprehensive proposal to 10 federal agencies. The organization has identified 44 specific regulations that it believes should be either significantly revised or completely eliminated under the Trump administration. This strategic initiative aims to reduce bureaucratic hurdles and create a more business-friendly regulatory environment. By targeting these regulations, NAM hopes to remove obstacles that potentially hinder manufacturing growth, innovation, and economic competitiveness. The detailed submission represents a collaborative effort to simplify complex regulatory frameworks, potentially saving businesses time, resources, and compliance costs. Each of the 44 targeted regulations was carefully analyzed to demonstrate how its modification or removal could benefit manufacturers across various industries. While the specific details of each recommended change were not immediately disclosed, the breadth of the proposal suggests a comprehensive approach to regulatory reform. The NAM's proactive stance underscores the organization's commitment to supporting American manufacturing and promoting economic efficiency. MORE...

From Factory Floor to Future: 5 Game-Changing Strategies for Smart Manufacturing Revolution

Manufacturing

2025-04-17 08:54:59

Unlocking the Power of Connected Manufacturing: Navigating the Path to Digital Transformation In today's rapidly evolving industrial landscape, connected manufacturing stands as a beacon of innovation and efficiency. While the potential benefits are undeniably compelling, Verizon acknowledges that the journey to digital transformation is far from straightforward. Modern manufacturers are increasingly recognizing the transformative potential of connected technologies. These advanced systems promise to revolutionize production processes, enhance operational visibility, and drive unprecedented levels of productivity. However, the road to implementation is often complex and demands careful strategic planning. The complexity of digital transformation stems from multiple factors. Organizations must carefully integrate new technologies with existing infrastructure, retrain workforce capabilities, and develop robust data management strategies. It's not simply about adopting new tools, but fundamentally reimagining manufacturing operations. Verizon emphasizes that successful connected manufacturing requires a holistic approach. Companies must: • Invest in cutting-edge connectivity solutions • Develop comprehensive digital strategies • Foster a culture of continuous innovation • Prioritize cybersecurity and data protection While the path may be challenging, the potential rewards are substantial. Connected manufacturing offers manufacturers the ability to optimize production, reduce downtime, improve quality control, and create more agile, responsive business models. The key is patience, strategic investment, and a commitment to ongoing digital evolution. As technology continues to advance, those who embrace connected manufacturing will be best positioned to thrive in an increasingly competitive global marketplace. MORE...

Silicon Mountain Ramps Up US Manufacturing Footprint in Strategic Expansion Move

Manufacturing

2025-04-17 08:41:36In response to the increasingly challenging global trade landscape, EMS provider Silicon Mountain Contract Services is taking decisive steps to bolster its domestic manufacturing capabilities. The company is strategically positioning itself to mitigate the risks posed by unpredictable international tariffs and ongoing supply chain disruptions. By expanding its domestic production infrastructure, Silicon Mountain aims to provide more resilient and flexible manufacturing solutions for its clients. This proactive approach not only helps insulate the company from global economic uncertainties but also supports the growing trend of reshoring manufacturing operations back to the United States. The move reflects a broader industry shift towards creating more robust and localized supply chains, ensuring greater reliability and faster response times for customers across various sectors. Silicon Mountain's commitment to domestic production demonstrates its adaptability and forward-thinking approach in a rapidly evolving manufacturing environment. MORE...

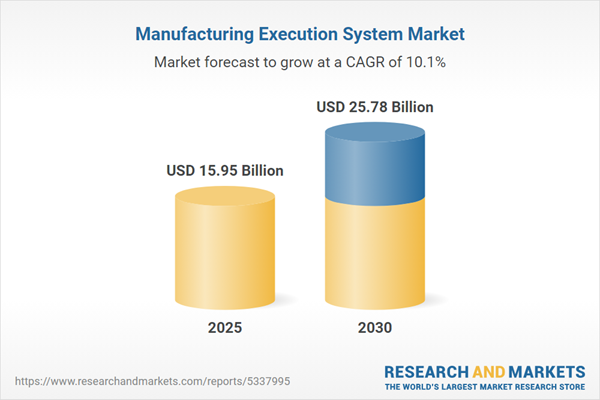

Factory Future: How Smart Manufacturing Systems Are Revolutionizing Global Production by 2030

Manufacturing

2025-04-17 08:33:00

The manufacturing landscape is undergoing a transformative revolution, propelled by cutting-edge technological advancements. At the forefront of this evolution are key drivers like Industry 4.0, smart factory innovations, and seamless real-time data integration, which are dramatically enhancing operational productivity and efficiency. The services segment is poised to dominate the market, driven by increasing integration requirements and the rapid growth of cloud-based Manufacturing Execution Systems (MES). While cloud adoption continues to gain momentum, on-premises MES solutions remain prominent, offering organizations superior data control and security. North America emerges as a critical growth hub, spearheading digital transformation across manufacturing sectors. Industry leaders such as Siemens, Dassault Systèmes, and Rockwell Automation are playing pivotal roles in shaping this dynamic technological ecosystem, driving innovation and setting new benchmarks for manufacturing excellence. As manufacturers increasingly embrace digital strategies, the convergence of advanced technologies promises to redefine production processes, creating more agile, intelligent, and responsive manufacturing environments. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238