Corporate Shuffle: Thierry Piéton's Strategic Career Leap

Manufacturing

2025-05-05 08:00:24

The manufacturing sector has experienced a dynamic month of leadership changes, with several high-profile CEO appointments and a notable CFO transition. This April has brought significant executive movements, highlighting the industry's ongoing evolution and strategic reshuffling. A particularly noteworthy development includes the career progression of a seasoned financial leader who has successfully guided the financial strategies of multiple global manufacturing enterprises. The recent leadership shifts underscore the manufacturing industry's commitment to innovation, adaptability, and strategic growth. As companies seek to navigate complex market challenges and technological transformations, these executive appointments signal a proactive approach to leadership and organizational development. MORE...

Zap-Proof Tech: How Semiconductor Giants Are Battling Invisible Electronic Threats

Manufacturing

2025-05-05 07:01:40

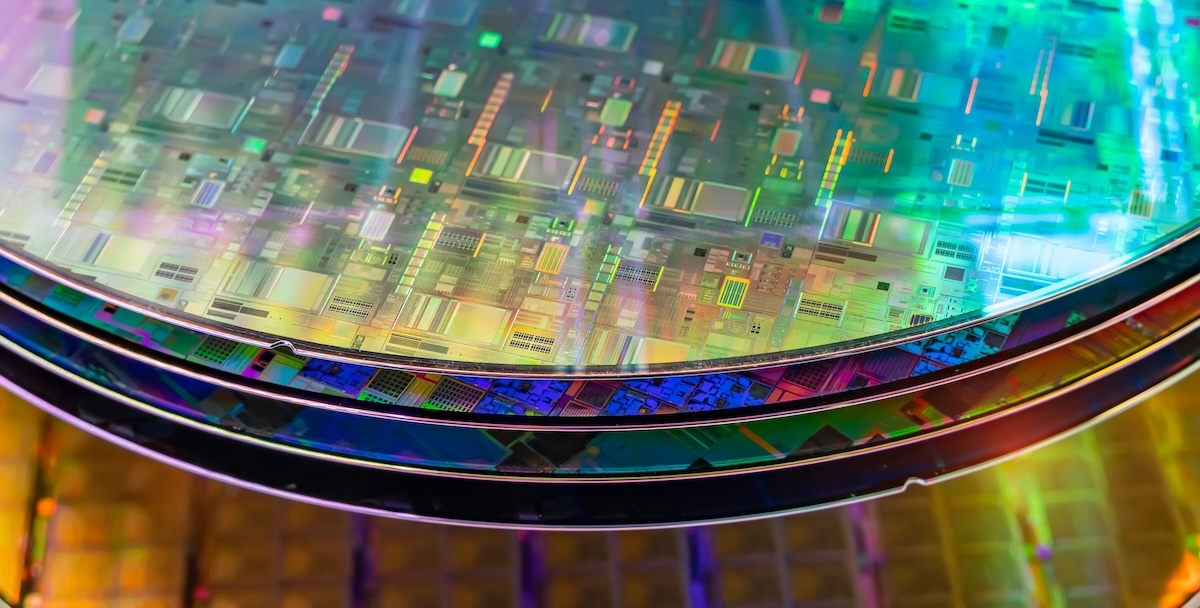

Breakthrough in Electrostatic Discharge Monitoring for Semiconductor Manufacturing

Researchers from National Yang Ming Chiao Tung University have unveiled a groundbreaking technical paper that promises to revolutionize electrostatic discharge (ESD) protection in semiconductor manufacturing. The innovative study, titled Real-Time ESD Monitoring and Control in Semiconductor Chip Environments, addresses a critical challenge in the electronics industry.

Integrated circuits are incredibly delicate and vulnerable to electrostatic discharge events, which can cause catastrophic damage to sensitive electronic components. The research team has developed a cutting-edge silicon chip capable of real-time detection and immediate alerting of potential ESD events, potentially saving millions of dollars in manufacturing losses.

By providing instantaneous monitoring and control mechanisms, this breakthrough technology offers semiconductor manufacturers an unprecedented level of protection against the invisible threat of electrostatic discharge. The novel approach could significantly improve production reliability and reduce costly equipment failures.

As electronic devices become increasingly complex and miniaturized, the importance of advanced ESD protection cannot be overstated. This research represents a significant step forward in safeguarding the intricate world of semiconductor manufacturing.

MORE...Precision Engineering Breakthrough: Huyett Revolutionizes Lifting Hardware Manufacturing

Manufacturing

2025-05-05 06:00:00

Huyett Unveils Significant Manufacturing Expansion in Phoenix Facility In a strategic move to enhance production capabilities, Huyett has announced a major expansion of its manufacturing operations at its Phoenix, Arizona facility. This significant investment demonstrates the company's commitment to strengthening its in-house production capabilities and meeting growing market demands. The expansion represents a pivotal moment for Huyett, positioning the company to improve operational efficiency, reduce production lead times, and deliver higher quality products to its customers. By investing in advanced manufacturing infrastructure, Huyett is reinforcing its competitive edge in the industry. With this facility upgrade, the company aims to streamline its production processes, leverage cutting-edge technologies, and create new opportunities for innovation and growth. The Phoenix facility will now serve as a key strategic asset in Huyett's manufacturing network. This expansion underscores Huyett's dedication to continuous improvement and its proactive approach to meeting the evolving needs of its clients across various sectors. MORE...

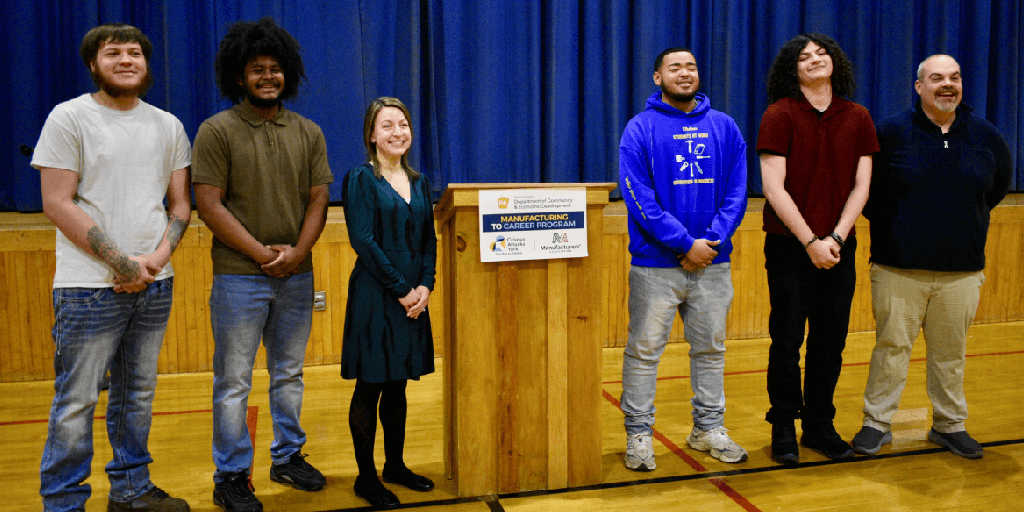

Cutting-Edge Manufacturing: Thomas County Schools Secure Innovative Grant to Boost Student Skills

Manufacturing

2025-05-05 00:34:59

THOMASVILLE — Exciting educational innovation is coming to Thomas County Schools this fall. The district has secured a substantial federal grant of over $87,000 from the Southwest Georgia Regional Commission, which will enable the launch of a groundbreaking Smart Manufacturing Pilot program at Thomas County Central High School. This significant funding represents a strategic investment in preparing local students for the cutting-edge technological landscape of modern manufacturing. By introducing this innovative pilot program, the school district aims to equip students with advanced skills and hands-on experience in smart manufacturing technologies, positioning them for future career opportunities in a rapidly evolving industrial sector. The Smart Manufacturing Pilot will provide students with unique insights into advanced manufacturing techniques, digital technologies, and industry-relevant skills that are increasingly crucial in today's competitive job market. This initiative underscores Thomas County Schools' commitment to providing forward-thinking educational experiences that bridge classroom learning with real-world industrial applications. MORE...

Manufacturing Momentum: Poland's Industrial Sector Shows Resilience Despite Cloudy Horizon

Manufacturing

2025-05-04 23:25:02

Poland's manufacturing sector showed resilience in April, with the Purchasing Managers' Index (PMI) maintaining a delicate balance just above the critical 50-point mark. According to the latest data from economic intelligence firm S&P Global, the index slightly declined by 0.5 points to 50.2, signaling a marginal expansion in industrial activity. The modest dip suggests that Polish manufacturers are navigating a complex economic landscape, managing to sustain growth despite ongoing challenges. While the decrease is subtle, it provides insights into the current state of the country's manufacturing sector and its ability to maintain momentum in a potentially uncertain economic environment. Economists and industry analysts will be closely monitoring future PMI readings to gauge the continued health and trajectory of Poland's industrial production in the coming months. MORE...

Manufacturing Prodigy: Local Student Clinches Coveted Spot in National Tech Showdown

Manufacturing

2025-05-04 14:00:00

tags. If you have the full article text, please share it, and I'll assist you right away. MORE...

Gears of Success: American Axle Defies Expectations with Strong Q1 Earnings Despite Revenue Challenges

Manufacturing

2025-05-04 13:40:36

American Axle & Manufacturing Holdings Delivers Strong Q1 2025 Financial Performance

American Axle & Manufacturing Holdings (NYSE:AXL) has reported impressive financial results for the first quarter of 2025, showcasing robust revenue and strategic operational strength.

Key Financial Highlights

- Revenue: The company achieved a substantial $1.41 billion in quarterly revenue, demonstrating solid market positioning and operational efficiency.

- Market Performance: The financial results reflect the company's continued resilience in the automotive manufacturing sector.

- Strategic Outlook: Management remains confident in the company's growth trajectory and ongoing technological innovations.

Investors and industry analysts are closely monitoring American Axle's performance as the automotive supply chain continues to evolve in the rapidly changing manufacturing landscape.

MORE...iPhone's Crossroads: Cook's Bold Move to Dodge Tariffs and Reshape US Manufacturing

Manufacturing

2025-05-04 13:28:59

Apple's Rollercoaster Week: Navigating Challenges and Opportunities In a dynamic week that showcased the tech giant's resilience and strategic adaptability, Apple found itself at the center of a multifaceted narrative that touched on trade tensions, manufacturing strategies, digital ecosystem evolution, and technological innovation. The company weathered a complex landscape of challenges, from potential tariff implications to exploring manufacturing alternatives, while simultaneously making strategic moves in its App Store policies and leveraging artificial intelligence to drive iPhone sales. These developments underscored Apple's ability to navigate an increasingly complex global technology marketplace. Investors and tech enthusiasts alike watched closely as the company demonstrated its trademark agility, responding to economic pressures and market dynamics with calculated precision. Each headline revealed another layer of Apple's sophisticated approach to maintaining its competitive edge in an ever-changing technological ecosystem. From trade negotiations to digital platform adjustments, Apple continued to prove why it remains a pivotal player in the global technology sector, balancing innovation, regulatory compliance, and strategic growth with remarkable finesse. MORE...

Manufacturing Boom: New Jersey Secures Massive $100M UAE Investment

Manufacturing

2025-05-04 12:14:25

I apologize, but it seems that the original article content is missing from your request. Without the original text, I cannot rewrite the article. Could you please provide the full text of the article you would like me to rewrite? Once I have the complete content, I'll be happy to help you create a more fluent and engaging version in HTML format. If you'd like me to generate a sample article, I can do that as well. But for an accurate rewrite, I would need the original text. MORE...

Tariff Tango: Inside a NYC Clothing Maker's Survival Struggle Under Trump's Trade Rollercoaster

Manufacturing

2025-05-04 12:00:00

Throughout our remarkable 35-year journey, our company has weathered numerous challenges and economic shifts. However, this current downturn represents an unprecedented moment in our history—a time when we've been compelled to make difficult decisions about our organizational structure that we've never faced before. The scale of our workforce reduction is not just a statistic, but a profound reflection of the complex economic landscape we're navigating. Our commitment to transparency and resilience remains unwavering, even as we adapt to these challenging circumstances. While this moment is undoubtedly challenging, we view it as an opportunity for strategic realignment and future growth. Our team's dedication and the strong foundation we've built over three and a half decades will guide us through this transformative period. MORE...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238