From Precision to Progress: Bentley's Quarter-Century Revolution in 3D Manufacturing

Manufacturing

2025-04-11 08:47:10Content

Bentley Motors Celebrates a Quarter-Century of Cutting-Edge 3D Printing Innovation

In a remarkable milestone, Bentley Motors is commemorating 25 years of groundbreaking Additive Manufacturing (AM) technology at its prestigious headquarters in Crewe. What began as an experimental technology has now become a cornerstone of the luxury automotive manufacturer's design and production processes.

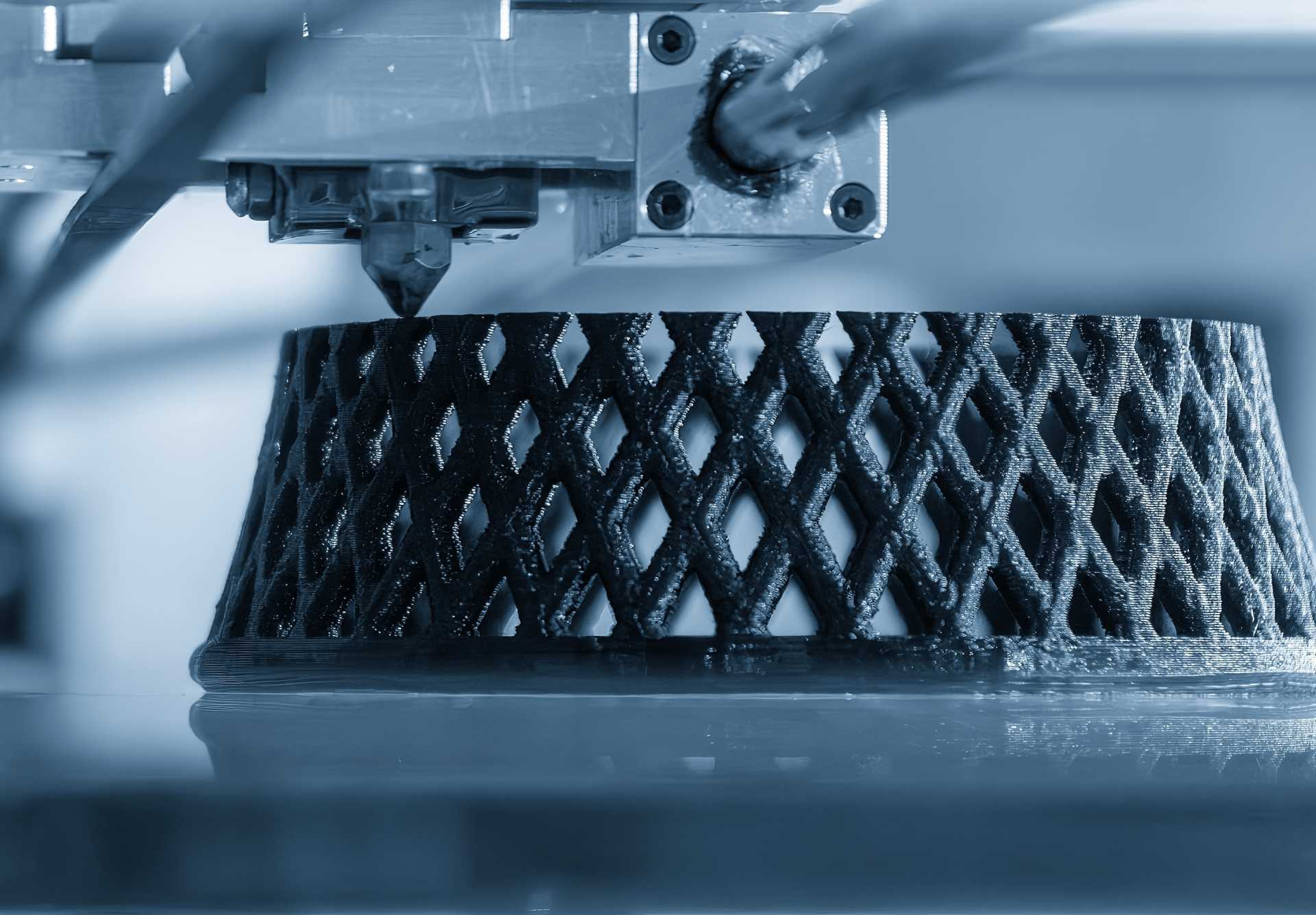

Over the past two and a half decades, 3D printing has revolutionized the way Bentley approaches prototype development, custom part creation, and intricate design solutions. The technology has enabled the brand to push the boundaries of automotive engineering, allowing for unprecedented levels of precision, creativity, and efficiency.

From rapid prototyping to creating complex components that would be impossible to manufacture through traditional methods, Bentley's commitment to additive manufacturing has been a key driver of its innovative spirit. The company has transformed 3D printing from a novel concept to an integral part of its manufacturing ecosystem, demonstrating how advanced technologies can reshape the future of luxury automotive design.

As Bentley reflects on 25 years of this transformative technology, it stands as a testament to the brand's forward-thinking approach and continuous pursuit of engineering excellence.

Revolutionizing Manufacturing: Bentley's Quarter-Century of 3D Printing Innovation

In the dynamic world of automotive manufacturing, technological breakthroughs have consistently reshaped how luxury vehicles are designed and produced. Bentley Motors stands at the forefront of this transformative journey, celebrating a remarkable milestone that demonstrates the company's commitment to cutting-edge manufacturing technologies and innovative engineering solutions.Where Precision Meets Technological Mastery: A Quarter-Century of Additive Manufacturing

The Evolution of Additive Manufacturing at Bentley

Bentley's journey into additive manufacturing represents a profound technological transformation that has fundamentally reimagined automotive production processes. Over the past 25 years, the luxury car manufacturer has strategically integrated 3D printing technologies, creating a revolutionary approach to design, prototyping, and component manufacturing. This technological evolution has not merely been about adopting new techniques, but about fundamentally reimagining what's possible in automotive engineering. The implementation of advanced 3D printing methodologies has enabled Bentley to dramatically reduce production times, minimize material waste, and create increasingly complex geometries that were previously impossible through traditional manufacturing techniques. Engineers and designers have leveraged these technologies to push the boundaries of automotive design, creating intricate components with unprecedented precision and structural integrity.Technological Innovations Driving Manufacturing Transformation

Additive manufacturing has emerged as a game-changing technology within Bentley's production ecosystem. By utilizing sophisticated 3D printing techniques, the company has developed capabilities that extend far beyond conventional manufacturing limitations. These technologies allow for rapid prototyping, customized component creation, and the ability to produce lightweight yet incredibly strong parts that enhance vehicle performance and efficiency. The computational complexity behind modern 3D printing technologies enables Bentley to experiment with advanced materials and intricate design configurations. From lightweight structural components to highly specialized interior elements, additive manufacturing has become a cornerstone of the company's innovative approach to automotive engineering.Sustainability and Efficiency in Modern Manufacturing

Bentley's commitment to additive manufacturing goes beyond technological prowess; it represents a strategic approach to sustainable production. By minimizing material waste and enabling more precise manufacturing processes, 3D printing technologies contribute significantly to reducing the environmental footprint of automotive production. The ability to create complex components with minimal material usage represents a paradigm shift in manufacturing philosophy. Each 3D-printed part potentially reduces weight, improves fuel efficiency, and demonstrates a commitment to more environmentally conscious production methodologies.Future Perspectives and Technological Horizons

As Bentley celebrates 25 years of additive manufacturing, the company looks forward to continued technological exploration. The next frontier involves integrating artificial intelligence, advanced computational modeling, and increasingly sophisticated 3D printing techniques to push the boundaries of what's achievable in automotive design and manufacturing. The ongoing evolution of these technologies promises even more remarkable innovations, potentially transforming not just how luxury vehicles are produced, but reimagining the entire concept of automotive engineering and design.RELATED NEWS

Manufacturing

Cooling Tech Revolution: LiquidStack Expands Texas Footprint with New Manufacturing Hub

2025-03-27 22:30:15

Manufacturing

Economic Boost: Local Manufacturer Unveils $11.5 Million Expansion, Promises Job Surge in Shelbyville

2025-04-25 00:22:00

Manufacturing

Biotech Titans Unite: Astellas and YASKAWA Forge Groundbreaking Cell Therapy Manufacturing Alliance

2025-03-06 04:02:00