Breaking Boundaries: How Two Innovators Are Revolutionizing Additive Manufacturing Testing

Manufacturing

2025-04-11 10:00:00Content

In the rapidly evolving world of additive manufacturing, precision and quality are paramount. Recently, industry experts Jerry Capo and Dr. Alex Kinsey sat down with Editor Lawrence Moebs to shed light on why rigorous testing has become more critical than ever in 3D printing technologies.

The conversation delved deep into the complexities of modern manufacturing, highlighting how advanced testing protocols can make the difference between breakthrough innovation and potential failure. Capo and Kinsey emphasized that as additive manufacturing continues to push technological boundaries, comprehensive testing is no longer just a recommended step—it's an absolute necessity.

Dr. Kinsey pointed out that the intricate nature of 3D printing processes demands meticulous examination at every stage. From material selection to final product verification, each step requires careful scrutiny to ensure structural integrity, performance, and reliability.

Jerry Capo added that emerging technologies are creating unprecedented challenges and opportunities in testing methodologies. "We're not just checking boxes," he explained, "we're developing sophisticated approaches that can predict and prevent potential manufacturing defects before they become costly problems."

Their insights underscore a crucial message: in additive manufacturing, testing isn't just about quality control—it's about pushing the boundaries of what's possible while maintaining the highest standards of precision and innovation.

Precision Unveiled: The Critical Role of Testing in Additive Manufacturing's Technological Frontier

In the rapidly evolving landscape of advanced manufacturing, the intersection of innovation and precision has never been more critical. As technological boundaries continue to expand, the importance of rigorous testing methodologies becomes paramount, particularly in the complex realm of additive manufacturing where every microscopic detail can determine the success or failure of groundbreaking engineering solutions.Revolutionizing Manufacturing: Where Precision Meets Possibility

The Technological Imperative of Comprehensive Testing

Additive manufacturing represents a paradigm shift in production technologies, challenging traditional manufacturing approaches with its unprecedented flexibility and complexity. The process of creating three-dimensional objects through layer-by-layer construction demands an extraordinary level of scientific scrutiny and technical validation. Unlike conventional manufacturing methods, additive manufacturing introduces unique challenges that require sophisticated testing protocols to ensure structural integrity, material consistency, and performance reliability. The intricate nature of these manufacturing techniques demands a multifaceted approach to quality assurance. Engineers and researchers must develop comprehensive testing strategies that can detect microscopic variations, material inconsistencies, and potential structural weaknesses that might compromise the final product's functionality. This requires an interdisciplinary approach that combines materials science, engineering principles, and advanced diagnostic technologies.Navigating the Complex Landscape of Material Verification

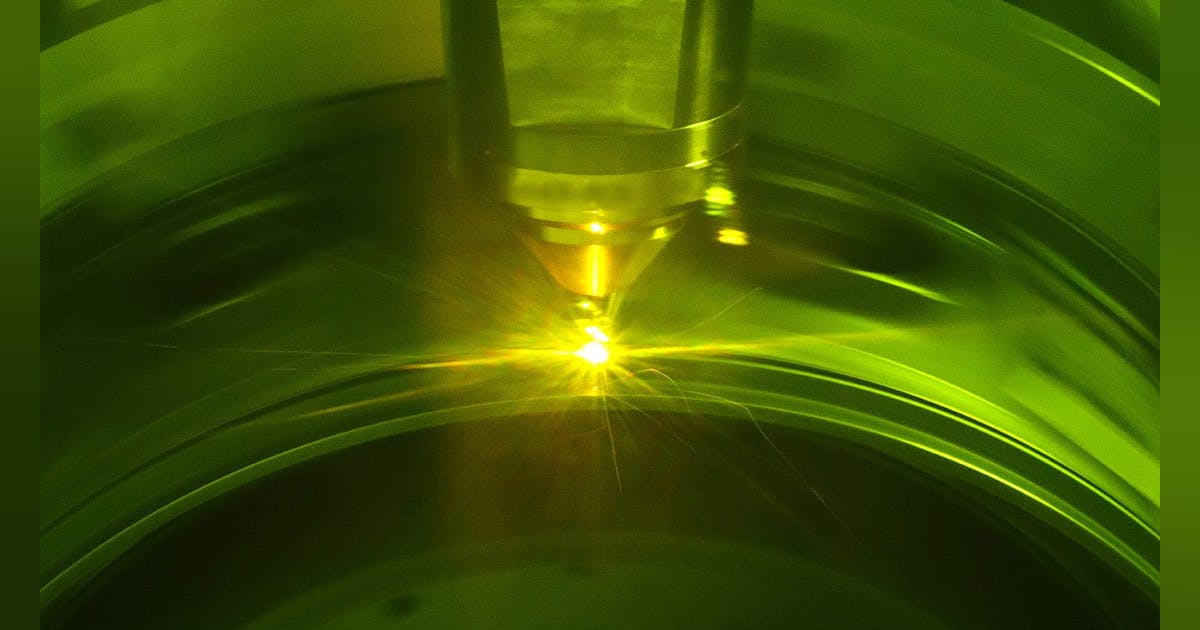

Material verification stands as a cornerstone of effective additive manufacturing testing. Each layer deposited during the manufacturing process represents a potential point of vulnerability, necessitating meticulous examination of material properties, thermal characteristics, and structural composition. Advanced non-destructive testing techniques, including ultrasonic scanning, X-ray tomography, and thermal imaging, have emerged as critical tools in understanding and validating the complex interactions occurring during the additive manufacturing process. Researchers like Dr. Alex Kinsey are pioneering innovative approaches to material testing that go beyond traditional quality control methods. By developing sophisticated diagnostic algorithms and leveraging machine learning technologies, these experts can predict potential manufacturing defects before they manifest, dramatically reducing waste and improving overall production efficiency.Technological Innovations Driving Testing Methodologies

The rapid evolution of testing technologies has transformed the additive manufacturing landscape. Cutting-edge sensors, real-time monitoring systems, and advanced computational models now enable manufacturers to capture unprecedented levels of detail during the production process. These technological innovations allow for instantaneous feedback, enabling immediate adjustments and ensuring consistently high-quality output. Artificial intelligence and machine learning algorithms are increasingly being integrated into testing protocols, providing predictive capabilities that were previously unimaginable. These systems can analyze complex datasets, identify potential anomalies, and recommend precise interventions, effectively transforming the testing process from a reactive to a proactive approach.Economic and Industrial Implications of Rigorous Testing

The economic ramifications of comprehensive testing extend far beyond immediate manufacturing concerns. Industries ranging from aerospace and automotive to medical device production are increasingly relying on additive manufacturing's precision and flexibility. However, the margin for error remains razor-thin, making robust testing protocols not just a technical necessity but a critical business imperative. By investing in advanced testing methodologies, manufacturers can significantly reduce production risks, minimize material waste, and accelerate innovation cycles. The ability to consistently produce high-quality, structurally sound components opens new frontiers of design and engineering possibilities, potentially revolutionizing entire industrial sectors.Future Perspectives: The Evolving Landscape of Additive Manufacturing Testing

As technological capabilities continue to expand, the future of additive manufacturing testing looks increasingly sophisticated and nuanced. Emerging technologies like quantum sensing, advanced computational modeling, and real-time molecular analysis promise to push the boundaries of what's possible in manufacturing quality assurance. The ongoing collaboration between academic researchers, industrial engineers, and technological innovators will be crucial in developing the next generation of testing methodologies. By continuing to challenge existing paradigms and embrace interdisciplinary approaches, the additive manufacturing community can unlock unprecedented levels of precision and reliability.RELATED NEWS

Manufacturing

Iowa Speedway Revs Up: Sukup Manufacturing Drives into INDYCAR Sponsorship

2025-04-10 16:30:53

Manufacturing

Kimberly-Clark's Bold $2B Bet: Supercharging US Manufacturing and Innovation

2025-05-01 18:06:00

Manufacturing

Wanted: Skilled Workers in Connecticut's Manufacturing Powerhouse - Why Electric Boat Can't Close the Talent Gap

2025-04-18 09:00:00