Manufacturing Mirage: Trump's Job Creation Quest Hits Roadblocks and Rising Costs

Manufacturing

2025-04-17 10:00:00Content

President Trump's ambitious manufacturing reshoring initiative is sending ripples of uncertainty through American industries, challenging businesses with rising costs and complex economic implications. While the administration aims to bring tens of thousands of manufacturing jobs back to U.S. soil, companies are grappling with the potential consequences of this dramatic economic shift.

Economists are increasingly skeptical about the feasibility and long-term sustainability of this aggressive manufacturing repatriation strategy. The push to relocate production from overseas threatens to disrupt carefully constructed global supply chains and potentially increase consumer prices across multiple sectors.

Many industries are finding themselves at a crossroads, weighing the patriotic appeal of domestic manufacturing against the economic realities of global competition. The potential benefits of job creation are being carefully balanced against the increased operational costs and potential reduction in international competitiveness.

As businesses navigate this complex landscape, the true impact of the administration's manufacturing strategy remains uncertain. Companies must now make critical decisions about their production models, weighing national economic goals against their own financial sustainability and global market positioning.

Manufacturing Metamorphosis: The Complex Landscape of Trump's Industrial Reshoring Strategy

In the intricate tapestry of American economic policy, the ambitious endeavor to repatriate manufacturing jobs has emerged as a pivotal and contentious strategy, challenging traditional economic paradigms and sparking intense debate among policymakers, industry leaders, and economic experts.Transforming Industrial Dynamics: A Bold Economic Gambit

The Geopolitical Underpinnings of Manufacturing Repatriation

The Trump administration's aggressive push to recalibrate the manufacturing ecosystem represents a profound departure from decades of globalization. By implementing strategic tariffs and policy interventions, the initiative seeks to fundamentally restructure industrial supply chains, compelling corporations to reconsider their offshore manufacturing strategies. Multinational corporations face unprecedented pressure to reevaluate their global production models. The economic calculus has shifted dramatically, with tax incentives, regulatory adjustments, and geopolitical tensions creating a complex decision-making environment for businesses contemplating domestic manufacturing investments.Economic Implications and Structural Challenges

Economists and industry analysts have identified significant hurdles in the manufacturing repatriation strategy. The intricate global supply networks developed over decades cannot be dismantled or reconstructed overnight without substantial economic disruption. Labor cost differentials, technological infrastructure, and workforce skill gaps present formidable challenges to rapid domestic manufacturing expansion. Companies must navigate complex technological transitions, workforce retraining programs, and substantial capital investments to successfully relocate production capabilities.Technological Innovation and Industrial Transformation

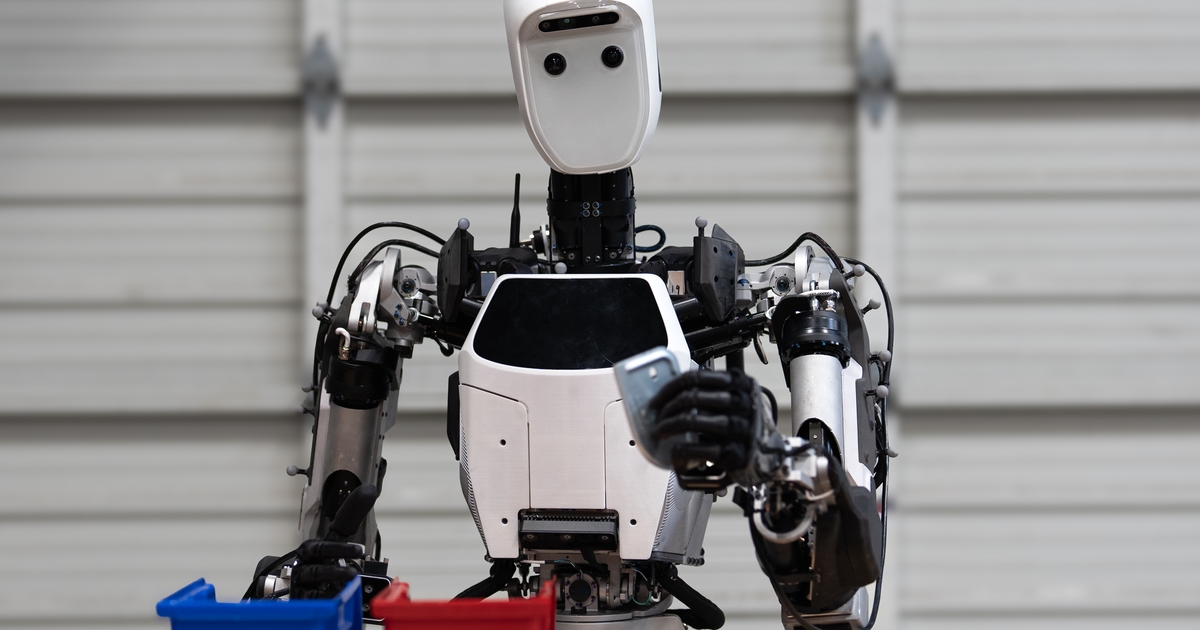

The manufacturing reshoring strategy intersects critically with technological innovation. Advanced robotics, artificial intelligence, and automated manufacturing processes are reshaping traditional employment models, creating a nuanced landscape where job creation doesn't necessarily correlate with historical employment patterns. Emerging technologies enable more efficient domestic production, potentially mitigating some traditional cost barriers associated with onshore manufacturing. However, this technological revolution simultaneously challenges workforce adaptation and skills development.Sectoral Variations and Strategic Adaptations

Different industrial sectors respond distinctively to reshoring initiatives. High-technology manufacturing, aerospace, pharmaceuticals, and precision engineering demonstrate varying capacities for domestic production reconstruction. Strategic investments in research and development, coupled with targeted government incentives, can accelerate sectoral transformations. However, each industry confronts unique challenges in recalibrating global supply chains and domestic production capabilities.Macroeconomic Ripple Effects

The manufacturing repatriation strategy generates complex macroeconomic reverberations. Trade relationships, international competitiveness, and global economic interdependencies are fundamentally challenged by this approach. Potential consequences include increased consumer prices, potential retaliatory trade measures from international partners, and long-term shifts in global economic power dynamics. The strategy represents a delicate balancing act between national economic sovereignty and global economic integration.Future Trajectory and Policy Considerations

Sustainable manufacturing repatriation requires holistic, long-term policy frameworks. Continuous adaptation, strategic investments in education and technological infrastructure, and nuanced understanding of global economic trends will be critical. Policymakers must develop flexible, forward-looking strategies that balance immediate economic objectives with long-term structural transformations. The success of manufacturing reshoring depends on sophisticated, multidimensional approaches that transcend simplistic protectionist narratives.RELATED NEWS

Manufacturing

Chips and Sovereignty: Nvidia's Bold Plan to Forge America's AI Supercomputer Empire

2025-04-16 07:00:56

Manufacturing

Automation Illusion: Why Robots Can't Solve America's Manufacturing Comeback

2025-05-02 04:00:27

Manufacturing

Behind the Curtain: How Takeda and Autolus Are Revolutionizing Cell Therapy Manufacturing

2025-03-19 23:59:07