Cutting-Edge Merger: United Performance Materials Expands Tech Horizons with Fabrisonic Acquisition

Manufacturing

2025-03-19 16:55:58Content

UPM and Fabrisonic: Revolutionizing Additive Manufacturing Through Strategic Collaboration

In a groundbreaking partnership, UPM and Fabrisonic are set to transform the additive manufacturing landscape, promising innovative solutions that will reshape technological capabilities across multiple industries. This strategic merger combines cutting-edge expertise and advanced manufacturing techniques to deliver unprecedented precision and performance.

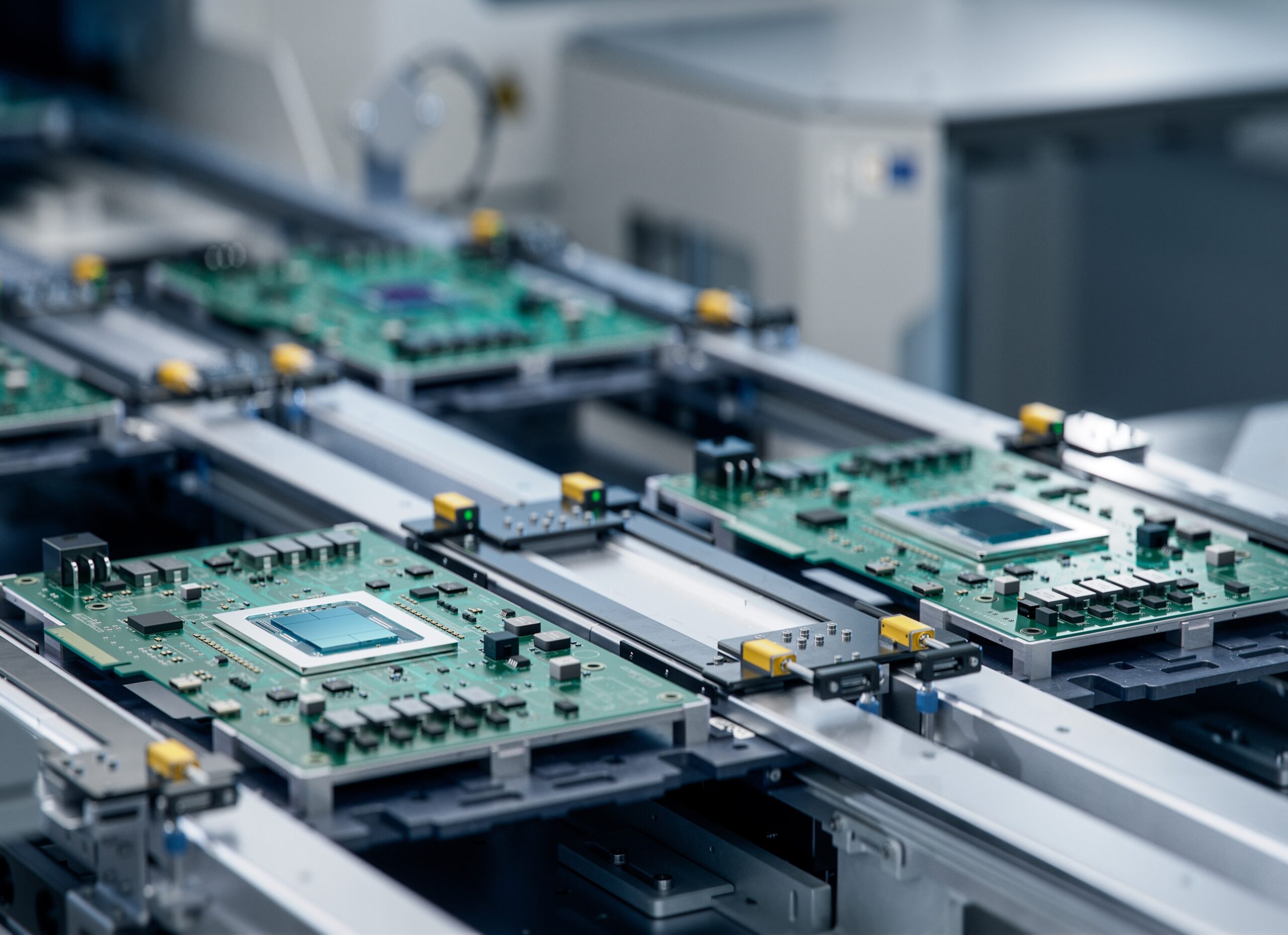

By leveraging Fabrisonic's pioneering ultrasonic additive manufacturing technology and UPM's extensive industrial experience, the collaboration aims to push the boundaries of what's possible in 3D printing and advanced material engineering. Their joint approach will enable more complex, lightweight, and high-performance components for sectors ranging from aerospace and automotive to medical and energy.

The merger represents a significant leap forward in additive manufacturing, offering manufacturers unprecedented opportunities to create intricate designs with superior material properties and enhanced structural integrity. Clients can now expect more sophisticated, customized solutions that were previously unimaginable.

As industries continue to demand more innovative and efficient manufacturing processes, this partnership positions UPM and Fabrisonic at the forefront of technological advancement, ready to meet the evolving challenges of modern engineering and design.

Revolutionary Metalworking Fusion: UPM and Fabrisonic Redefine Additive Manufacturing Frontiers

In the rapidly evolving landscape of advanced manufacturing, strategic partnerships are reshaping technological boundaries, driving innovation that promises to transform industrial production paradigms. The convergence of cutting-edge technologies and visionary corporate strategies represents a pivotal moment in engineering and materials science.Pioneering the Future of Multi-Metal Additive Manufacturing

Technological Synergy and Strategic Collaboration

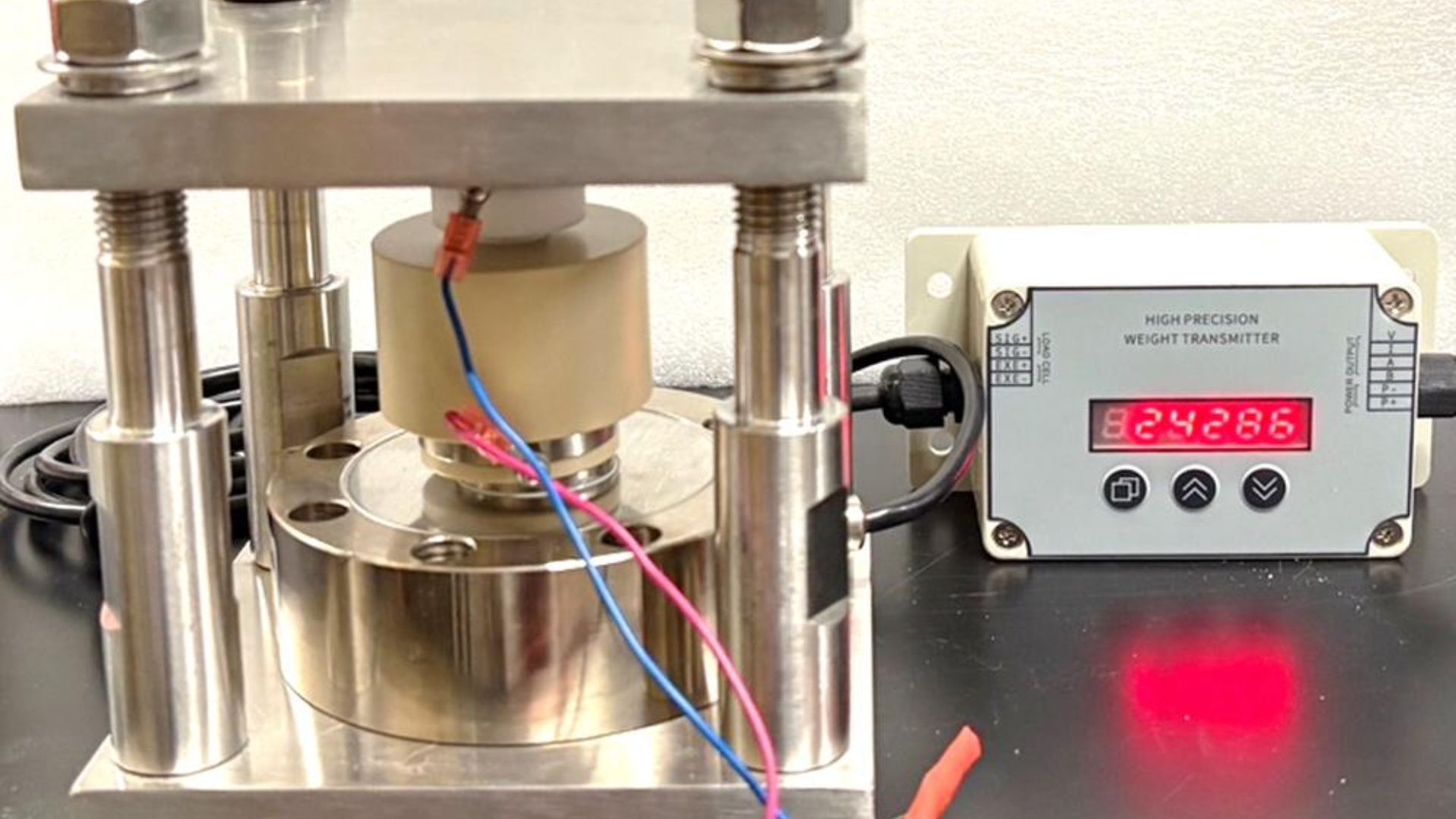

The merger between UPM and Fabrisonic represents a groundbreaking milestone in additive manufacturing technology. By combining their respective expertise, these industry leaders are poised to unlock unprecedented capabilities in multi-metal fabrication techniques. Their collaborative approach transcends traditional manufacturing limitations, introducing revolutionary methodologies that challenge existing production constraints. The integration of ultrasonic additive manufacturing (UAM) with advanced material engineering creates a transformative platform for complex component development. This innovative approach enables unprecedented precision in creating intricate metallic structures with multi-material compositions, offering manufacturers extraordinary design flexibility and performance potential.Advanced Manufacturing Capabilities and Industrial Applications

Ultrasonic additive manufacturing emerges as a game-changing technology, enabling unprecedented material manipulation and structural complexity. By leveraging high-frequency sound waves and sophisticated bonding techniques, manufacturers can now produce components with intricate geometries and enhanced mechanical properties that were previously unimaginable. The technological breakthrough extends across multiple industrial sectors, including aerospace, automotive, medical device manufacturing, and advanced engineering. Potential applications range from lightweight aerospace components to sophisticated medical implants, demonstrating the remarkable versatility of this innovative manufacturing approach.Material Science and Engineering Innovations

The merger's technological implications extend far beyond traditional manufacturing boundaries. By developing sophisticated multi-metal fabrication techniques, UPM and Fabrisonic are pioneering new frontiers in material science, enabling engineers to create hybrid structures with tailored mechanical, thermal, and electrical characteristics. This approach allows for unprecedented material customization, where different metals can be seamlessly integrated within a single component. The ability to strategically combine materials with distinct properties opens up revolutionary design possibilities, potentially transforming how engineers conceptualize and develop complex mechanical systems.Economic and Technological Implications

The strategic partnership between UPM and Fabrisonic represents more than a mere technological collaboration; it signifies a paradigm shift in manufacturing economics. By reducing material waste, minimizing production complexity, and enabling more efficient design processes, this innovative approach promises significant cost reductions and enhanced product performance. Manufacturers across various industries can leverage these advanced techniques to develop more sophisticated, lightweight, and high-performance components. The potential for reduced production times, improved material utilization, and enhanced design flexibility positions this technology as a critical driver of future industrial innovation.Global Manufacturing Transformation

As global manufacturing continues to evolve, technologies like ultrasonic additive manufacturing will play an increasingly pivotal role in shaping industrial landscapes. The UPM and Fabrisonic collaboration exemplifies how strategic technological partnerships can drive meaningful technological progress, pushing the boundaries of what's possible in materials engineering and manufacturing. By combining expertise, resources, and visionary thinking, these companies are not just developing new technologies—they are reimagining the fundamental principles of industrial production, setting new standards for innovation, efficiency, and technological excellence.RELATED NEWS

Tech Titans Unite: Ynvisible and CCL Design Forge Groundbreaking Manufacturing Alliance