Velo3D Accelerates Manufacturing: Breakthrough Rapid Production Solutions Unveiled

Manufacturing

2025-03-19 13:18:19Content

Revolutionizing Supply Chains: Velo3D's Cutting-Edge Rapid Production Solutions

In today's dynamic global marketplace, businesses are constantly seeking innovative strategies to build resilient and adaptable supply chains. Velo3D emerges as a game-changing technology partner, offering advanced manufacturing solutions that transform traditional production paradigms.

The Power of Advanced Manufacturing Technology

Velo3D's rapid production solutions represent a quantum leap in manufacturing capabilities. By leveraging state-of-the-art 3D printing technologies, companies can now:

- Dramatically reduce production lead times

- Minimize inventory holding costs

- Create complex geometries previously impossible with conventional manufacturing

- Enhance supply chain flexibility and responsiveness

Breaking Traditional Manufacturing Limitations

Traditional manufacturing methods often impose significant constraints on design and production. Velo3D's innovative approach eliminates these barriers, enabling businesses to:

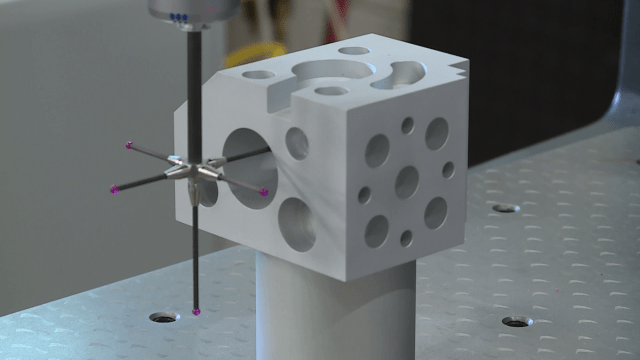

- Produce intricate components with unprecedented precision

- Optimize material usage and reduce waste

- Accelerate product development cycles

- Implement on-demand manufacturing strategies

Building Resilience Through Technology

In an era of global uncertainty, Velo3D's rapid production solutions provide companies with a strategic advantage. By decentralizing production and enabling rapid prototyping and manufacturing, businesses can:

- Mitigate supply chain disruptions

- Reduce dependency on traditional manufacturing networks

- Quickly adapt to changing market demands

- Maintain competitive edge through technological innovation

Embrace the future of manufacturing with Velo3D's revolutionary rapid production solutions – where innovation meets resilience.

Revolutionizing Manufacturing: The Future of Advanced Production Technologies

In the rapidly evolving landscape of industrial innovation, cutting-edge manufacturing solutions are transforming how businesses approach production challenges, pushing the boundaries of what's possible in advanced technological ecosystems.Unleashing Unprecedented Manufacturing Potential Through Breakthrough Technologies

The Paradigm Shift in Advanced Manufacturing

Modern manufacturing is experiencing a profound transformation driven by revolutionary technological breakthroughs. Companies are increasingly recognizing the critical importance of integrating sophisticated production methodologies that transcend traditional manufacturing limitations. These advanced systems represent more than mere technological upgrades; they embody a comprehensive reimagining of industrial capabilities. The convergence of precision engineering, adaptive manufacturing techniques, and intelligent design principles is creating unprecedented opportunities for businesses seeking to optimize their production processes. By leveraging state-of-the-art technologies, organizations can dramatically enhance their operational efficiency, reduce resource consumption, and accelerate innovation cycles.Technological Innovations Driving Industrial Transformation

Cutting-edge production solutions are fundamentally reshaping industrial landscapes by introducing unprecedented levels of flexibility and precision. Advanced manufacturing platforms enable organizations to develop complex geometries and intricate components that were previously impossible or prohibitively expensive to produce. These transformative technologies integrate sophisticated computational modeling, advanced materials science, and intelligent automation systems. By combining these elements, manufacturers can create highly customized production environments that adapt dynamically to changing market demands and technological requirements.Strategic Advantages of Next-Generation Production Technologies

Organizations implementing advanced manufacturing technologies gain substantial competitive advantages. These sophisticated systems provide unparalleled capabilities in design complexity, material optimization, and production scalability. Manufacturers can now develop intricate components with microscopic tolerances, reducing waste and enhancing overall product performance. The strategic implications extend beyond immediate production capabilities. Companies embracing these technologies position themselves at the forefront of industrial innovation, attracting top talent, securing strategic partnerships, and establishing themselves as technological leaders in their respective domains.Economic and Environmental Implications

Advanced production technologies are not just technological marvels; they represent critical solutions to global economic and environmental challenges. By enabling more efficient manufacturing processes, these innovations contribute to significant reductions in energy consumption, material waste, and carbon emissions. The economic potential is equally transformative. Organizations can dramatically reduce production costs, accelerate time-to-market, and create more sophisticated, high-performance products. This approach represents a holistic strategy for sustainable industrial development, balancing technological advancement with environmental responsibility.Future Trajectory of Manufacturing Technologies

The ongoing evolution of production technologies suggests an increasingly integrated, intelligent, and adaptive manufacturing ecosystem. Emerging technologies like artificial intelligence, machine learning, and advanced robotics will continue to push the boundaries of what's achievable in industrial production. Businesses that proactively invest in these technological capabilities will be best positioned to navigate the complex, rapidly changing global manufacturing landscape. The future belongs to organizations that can seamlessly blend human creativity with technological precision, creating innovative solutions that address complex global challenges.RELATED NEWS

Manufacturing Mavericks: Berks Schuylkill Honors Innovators in Groundbreaking 2025 Awards

Gold Prices Steady as NY Manufacturing Data Signals Economic Resilience