Honda's Bold Move: Supercharging American Manufacturing Landscape

Manufacturing

2025-04-15 15:49:38Content

In a bold strategic move, the automaker has set an ambitious goal to dramatically localize its production, aiming to manufacture 90% of its vehicles sold in the United States within the country's borders. This initiative underscores a strong commitment to domestic manufacturing, potentially reshaping the automotive landscape and supporting American jobs.

By prioritizing U.S.-based production, the company signals a significant shift towards strengthening its domestic manufacturing capabilities. This approach not only promises to boost local employment but also demonstrates a strategic investment in the nation's industrial infrastructure. The plan reflects a growing trend of companies seeking to reduce international supply chain dependencies and create more resilient production networks.

The automaker's vision goes beyond mere numbers, representing a comprehensive strategy to enhance local economic growth and maintain competitive advantage in an increasingly complex global market. As the automotive industry continues to evolve, this commitment to domestic manufacturing could serve as a powerful model for other manufacturers looking to invest in American production capabilities.

American Automotive Revolution: Reshaping Manufacturing Landscape

In an era of unprecedented industrial transformation, the automotive sector stands at a critical crossroads, with manufacturers strategically repositioning their production paradigms to align with emerging economic and technological landscapes. The push towards domestic manufacturing represents more than a mere business strategy—it signals a profound shift in national industrial policy and economic resilience.Driving Domestic Production: A Bold Industrial Mandate

The Strategic Imperative of Localized Manufacturing

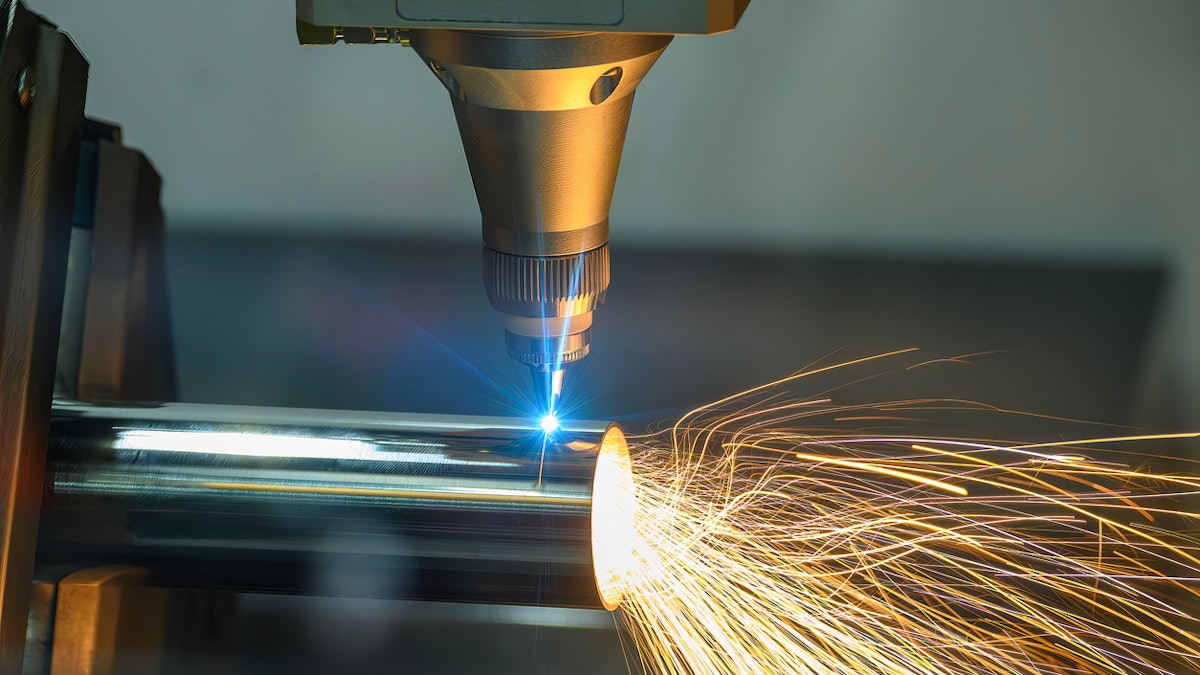

The automotive industry is experiencing a seismic transformation, with manufacturers increasingly recognizing the strategic advantages of localizing production. By concentrating manufacturing capabilities within national borders, companies can mitigate complex global supply chain vulnerabilities, reduce transportation costs, and create substantial domestic employment opportunities. This approach transcends traditional economic models, representing a nuanced strategy of economic self-sufficiency and technological innovation. Domestic production offers multifaceted benefits beyond immediate economic considerations. It enables more agile response mechanisms to market fluctuations, enhances quality control protocols, and provides greater flexibility in product development and customization. Manufacturers are discovering that proximity to production facilities allows for more rapid prototyping, faster market entry, and more responsive customer engagement strategies.Technological Infrastructure and Manufacturing Capabilities

The transition towards domestic manufacturing requires substantial investments in technological infrastructure and workforce development. Advanced robotics, artificial intelligence, and precision manufacturing technologies are becoming integral components of this transformation. Companies are not merely relocating production lines but fundamentally reimagining manufacturing ecosystems that blend human expertise with cutting-edge technological capabilities. Modern manufacturing facilities are evolving into sophisticated technological hubs, where automation and human skill converge to create unprecedented levels of efficiency and innovation. These facilities represent more than production centers—they are laboratories of industrial creativity, driving technological advancement and economic competitiveness.Economic and Geopolitical Implications

The push for domestic automotive production carries profound geopolitical significance. By reducing dependence on international supply chains, nations can enhance economic sovereignty and strategic resilience. This approach mitigates risks associated with global trade disruptions, geopolitical tensions, and potential international economic uncertainties. Moreover, localized manufacturing stimulates broader economic ecosystems. It generates employment across multiple sectors, from advanced engineering to skilled trades, creating a multiplier effect that extends far beyond the automotive industry itself. The ripple effects of such strategic manufacturing decisions can reshape regional economic landscapes and contribute to national economic revitalization.Sustainability and Environmental Considerations

Domestic manufacturing also intersects critically with sustainability objectives. Reduced transportation distances translate directly into lower carbon emissions, supporting broader environmental conservation goals. Advanced domestic facilities can more readily implement stringent environmental standards, driving innovation in sustainable manufacturing practices. The automotive sector's commitment to domestic production represents a holistic approach to industrial development—balancing economic pragmatism with environmental responsibility. By localizing production, manufacturers are not just making a business decision but participating in a broader narrative of sustainable industrial transformation.Future Outlook and Transformative Potential

As technological capabilities continue evolving, domestic automotive manufacturing will likely become increasingly sophisticated. Artificial intelligence, advanced materials science, and innovative production methodologies will reshape traditional manufacturing paradigms, creating more efficient, adaptable, and responsive industrial ecosystems. The current momentum towards domestic production signals a fundamental reimagining of industrial strategy—a shift from globalized, dispersed manufacturing towards more integrated, technologically advanced, and locally rooted production models. This transformation represents not just an industrial trend but a comprehensive reevaluation of how nations conceptualize economic development and technological innovation.RELATED NEWS

Manufacturing

How Microsoft Dynamics 365 Is Revolutionizing the Manufacturing Landscape

2025-04-02 19:00:00

Manufacturing

Breaking Barriers: Local Teen Girls Discover the Power of Manufacturing at Black Hawk College

2025-03-08 00:41:00

Manufacturing

Cramer's Bullish Bet: Why Taiwan Semi Could Be the Tech Stock That Changes Everything

2025-03-29 13:46:26