Robotic Revolution: How ABB and Molg Are Transforming Waste into Circular Economy Gold

Manufacturing

2025-03-11 11:30:00Content

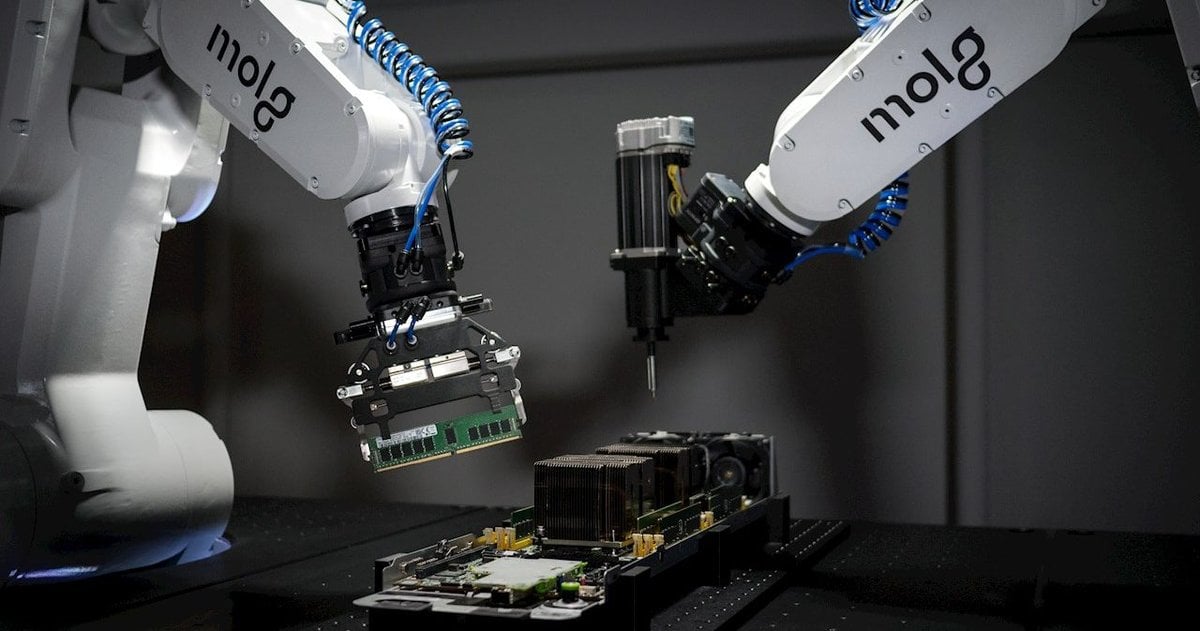

In a strategic move towards sustainability, ABB Motion's Drive Products division has forged a groundbreaking partnership with circular manufacturer Molg. This collaboration aims to revolutionize the design and manufacturing process of ABB drives, with a primary focus on enhancing reusability and implementing circular economy principles.

By joining forces with Molg, ABB Motion is demonstrating its commitment to innovative, environmentally conscious product development. The partnership will leverage Molg's expertise in circular manufacturing to optimize drive product design, potentially reducing waste and creating more sustainable industrial solutions.

This investment signals ABB's forward-thinking approach to manufacturing, emphasizing the importance of circular design in modern industrial engineering. Through this strategic collaboration, the company is poised to set new standards in drive product sustainability and efficiency.

Revolutionizing Industrial Design: ABB Motion's Strategic Partnership with Molg Transforms Drive Manufacturing

In the rapidly evolving landscape of industrial engineering, strategic partnerships are becoming increasingly critical for technological innovation and sustainable manufacturing. The collaboration between ABB Motion's Drive Products division and circular manufacturer Molg represents a groundbreaking approach to reimagining industrial design and environmental responsibility.Pioneering Sustainable Manufacturing Through Innovative Collaboration

The Strategic Vision of Circular Manufacturing

The partnership between ABB Motion and Molg emerges as a transformative moment in industrial engineering, signaling a profound shift towards more sustainable and intelligent manufacturing processes. By focusing on optimizing drive product design for enhanced reusability, the collaboration challenges traditional linear manufacturing paradigms. This strategic initiative goes beyond mere technological advancement, representing a holistic approach to industrial innovation that considers environmental impact, resource efficiency, and long-term sustainability. The intricate process of redesigning drive systems involves complex engineering considerations, including material selection, structural integrity, and lifecycle assessment. Molg's expertise in circular manufacturing provides ABB Motion with unique insights into creating products that can be more easily disassembled, repurposed, and recycled. This approach not only reduces waste but also creates economic value by extending the functional lifespan of industrial components.Technological Innovation in Drive Product Design

ABB Motion's investment in Molg represents a sophisticated approach to technological innovation. By integrating circular manufacturing principles, the company aims to fundamentally reimagine how industrial drives are conceptualized, manufactured, and ultimately recycled. This strategy involves developing advanced design methodologies that prioritize modularity, material efficiency, and end-of-life recyclability. The technical challenges of creating reusable drive systems are substantial. Engineers must develop components that can withstand rigorous industrial environments while maintaining structural flexibility for future repurposing. This requires advanced materials science, precision engineering, and a deep understanding of industrial performance requirements. Molg's specialized knowledge in circular manufacturing provides critical insights into achieving these complex design objectives.Environmental and Economic Implications

The collaboration between ABB Motion and Molg extends far beyond technological innovation, representing a significant step towards sustainable industrial practices. By prioritizing reusability and circular design principles, the partnership addresses critical environmental challenges while simultaneously creating economic opportunities. The approach demonstrates how strategic investments in sustainable technology can generate value across multiple dimensions. Industrial sectors worldwide are increasingly recognizing the importance of circular economy principles. This partnership serves as a compelling case study, illustrating how sophisticated engineering and environmental consciousness can coexist. The potential impact reaches beyond individual product lines, potentially influencing broader manufacturing strategies across multiple industries.Future Perspectives in Industrial Design

As global industries confront mounting environmental challenges, collaborations like the one between ABB Motion and Molg become increasingly significant. The partnership represents more than a technological investment; it embodies a philosophical approach to industrial design that prioritizes sustainability, efficiency, and long-term value creation. The ongoing development of this strategic relationship promises to yield innovative solutions that could reshape how industrial drives are conceived, manufactured, and ultimately recycled. By challenging existing manufacturing paradigms, ABB Motion and Molg are positioning themselves at the forefront of a potential industrial design revolution.RELATED NEWS

Manufacturing

Trade Tensions: How Trump's Tariffs Are Derailing Gen Z's Automotive Career Dreams

2025-05-05 16:10:48

Manufacturing

Silicon Setback: Intel's Ohio Megafab Hits Unexpected Roadblock, Launch Pushed to 2030

2025-02-28 14:53:22

Manufacturing

Sheet Metal Revolution: Texas Powerhouse Clinches Prestigious Fabrication Honor

2025-05-05 15:38:30