Green Energy Exodus: Massive Project Cancellations Signal Urgent Industry Shift

Manufacturing

2025-04-17 08:00:00Content

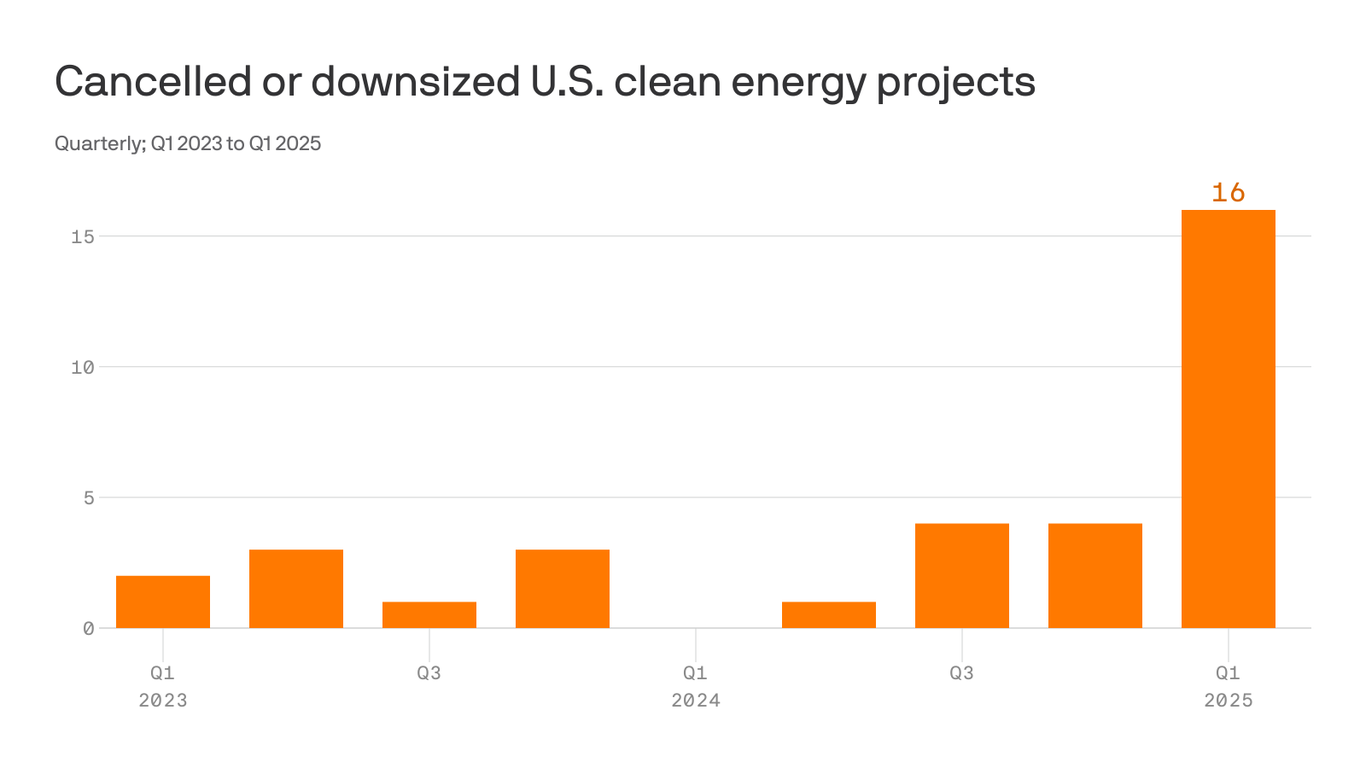

In a striking trend reflecting economic uncertainty, manufacturers have dramatically scaled back expansion plans, with 16 companies canceling or postponing factory projects since the start of 2024. This significant pullback signals growing caution in the industrial sector, as businesses reassess their growth strategies amid complex market conditions.

The sudden reversal of factory plans highlights the delicate balance companies are navigating between potential growth opportunities and economic risks. Factors such as fluctuating market demand, rising construction costs, and uncertain supply chain dynamics appear to be driving these strategic retreats.

Industry experts suggest that this trend could be a bellwether for broader economic challenges, indicating that businesses are adopting a more conservative approach to capital investments. The widespread nature of these project cancellations spans multiple sectors, from manufacturing to technology, underscoring the pervasive economic hesitation.

While the exact motivations vary by company, the consistent theme seems to be a careful reevaluation of expansion strategies in an increasingly unpredictable business landscape. Investors and economic analysts are closely watching these developments as potential indicators of future economic momentum.

Industrial Reshaping: The Dramatic Pause in Factory Expansion Strategies

In the rapidly evolving landscape of global manufacturing, a seismic shift is underway as companies strategically recalibrate their industrial footprint. The unprecedented pause in factory development signals a complex interplay of economic, geopolitical, and technological factors that are reshaping the industrial ecosystem.Navigating Uncertainty: How Strategic Decisions Are Transforming Manufacturing Landscapes

Economic Recalibration and Strategic Realignment

The contemporary manufacturing sector is experiencing a profound transformation, driven by multifaceted economic pressures. Companies are no longer approaching factory expansions with traditional linear strategies. Instead, they're adopting nuanced, data-driven approaches that consider global supply chain volatilities, geopolitical tensions, and emerging technological disruptions. Sophisticated risk assessment models are now fundamental in corporate decision-making processes. Executives are meticulously analyzing potential investment scenarios, weighing short-term operational costs against long-term strategic advantages. This intricate evaluation goes beyond conventional financial metrics, incorporating complex variables like geopolitical stability, technological infrastructure, and potential market shifts.Technological Disruption and Infrastructure Challenges

The current manufacturing landscape is characterized by unprecedented technological complexity. Artificial intelligence, advanced robotics, and sophisticated automation technologies are fundamentally restructuring traditional factory development paradigms. Companies are increasingly prioritizing adaptable, technology-ready infrastructures over massive, static manufacturing facilities. This technological revolution demands significant capital investment and strategic foresight. Manufacturers are carefully selecting locations that offer not just cost advantages, but robust digital ecosystems, skilled workforce availability, and potential for future technological integration. The 16 factory plans reversed since the beginning of the year represent a strategic pause, allowing companies to recalibrate their technological readiness.Geopolitical Dynamics and Supply Chain Resilience

Global geopolitical tensions are playing a critical role in reshaping manufacturing strategies. Trade uncertainties, regional conflicts, and evolving international regulations are compelling companies to adopt more flexible, decentralized production models. The traditional concept of centralized manufacturing is giving way to distributed, resilient supply chain architectures. Organizations are strategically diversifying their manufacturing footprints, reducing dependency on single geographic regions. This approach mitigates risks associated with potential disruptions, whether they stem from political instability, pandemic-related challenges, or unexpected global events. The reversal of factory plans reflects a sophisticated risk management strategy rather than a simple retreat.Environmental Considerations and Sustainable Manufacturing

Sustainability has transitioned from a peripheral concern to a central strategic imperative. Modern manufacturers are integrating comprehensive environmental considerations into their factory development strategies. This involves evaluating carbon footprints, exploring renewable energy integration, and designing facilities with circular economy principles. The paused factory expansions likely reflect a deeper commitment to sustainable development. Companies are investing time in redesigning proposed facilities to meet increasingly stringent environmental standards, potentially incorporating cutting-edge green technologies and innovative waste management systems.Financial and Investment Landscape

The current manufacturing investment environment is characterized by heightened complexity and cautious optimism. Traditional financing models are being reimagined, with increased emphasis on flexible capital allocation, risk-sharing mechanisms, and technology-enabled investment strategies. Venture capital and strategic investors are demanding more comprehensive due diligence, looking beyond immediate financial returns to assess long-term technological adaptability and strategic alignment. The 16 reversed factory plans represent a sophisticated approach to capital deployment, prioritizing strategic flexibility over immediate expansion.RELATED NEWS

Manufacturing

Breaking Barriers: How CEAT is Revolutionizing Manufacturing Through Women's Empowerment

2025-04-17 14:50:00

Manufacturing

Manufacturing Momentum Stalls: How Trump's Shadow Looms Over Biden's Industrial Dream

2025-04-10 16:49:23