Factory Future: 6 Manufacturing Careers Set to Explode in 2025

Manufacturing

2025-02-28 21:26:48Content

The Future of Work: Emerging Career Paths in Advanced Manufacturing

As technology continues to revolutionize the industrial landscape, several exciting career opportunities are emerging for skilled professionals. From precision engineering to cutting-edge digital manufacturing, the sector is experiencing a remarkable transformation that promises lucrative and dynamic career paths.

Top Growth Career Markets in Manufacturing for 2025 and Beyond

- Industrial Machinery Mechanics: These technical experts are becoming increasingly crucial as complex machinery requires sophisticated maintenance and repair skills.

- Computer Numerical Control (CNC) Programming: With automation driving manufacturing innovation, CNC programmers are in high demand, bridging the gap between traditional manufacturing and advanced digital technologies.

- Advanced Robotics Technicians: As smart factories become the norm, professionals who can design, program, and maintain robotic systems are finding unprecedented career opportunities.

- Industrial Internet of Things (IIoT) Specialists: Professionals who can integrate and manage interconnected manufacturing systems are becoming indispensable in modern industrial environments.

These emerging career paths not only offer competitive salaries but also provide professionals with the chance to be at the forefront of technological innovation in manufacturing.

Revolutionizing Manufacturing: The Future of Industrial Career Landscapes in 2025

In the rapidly evolving world of industrial production, the manufacturing sector stands on the brink of a transformative era. As technological advancements continue to reshape traditional workplace dynamics, professionals are witnessing unprecedented opportunities for career growth and innovation. The landscape of manufacturing jobs is no longer confined to traditional roles but is expanding into sophisticated, technology-driven domains that demand cutting-edge skills and adaptive expertise.Unlock Your Potential: Breakthrough Careers Reshaping Industrial Excellence

The Digital Revolution in Manufacturing Workforce

The manufacturing industry is experiencing a profound metamorphosis driven by technological integration. Emerging professionals are no longer confined to manual labor but are becoming sophisticated technological architects. Advanced automation, artificial intelligence, and complex computational systems are redefining job requirements, creating opportunities for individuals with multidisciplinary skill sets. Modern manufacturing careers demand a unique blend of technical proficiency and strategic thinking. Professionals must navigate intricate technological ecosystems, understanding how sophisticated machinery interfaces with human expertise. This requires continuous learning and adaptability, transforming traditional manufacturing roles into dynamic, intellectually challenging career paths.Computational Manufacturing: Beyond Traditional Programming

Computer numerical control (CNC) programming has evolved from a niche technical skill to a critical competency in contemporary manufacturing environments. These professionals are now digital engineers, translating complex design concepts into precise mechanical instructions that drive sophisticated manufacturing processes. The role extends far beyond traditional programming, encompassing advanced problem-solving, system optimization, and innovative design strategies. CNC programmers are essentially the bridge between creative conceptualization and mechanical execution, utilizing advanced software platforms to transform abstract ideas into tangible industrial solutions.Industrial Machinery Mechanics: The New Technological Guardians

Industrial machinery mechanics have transformed from traditional maintenance workers to high-tech diagnostic specialists. These professionals now utilize advanced diagnostic tools, predictive maintenance technologies, and complex analytical systems to ensure optimal machinery performance. Their expertise requires a comprehensive understanding of mechanical systems, electronic interfaces, and emerging technological trends. Modern mechanics are essentially technological physicians, diagnosing complex machinery issues, implementing preventative strategies, and ensuring seamless operational continuity across sophisticated industrial environments.Emerging Technological Specializations in Manufacturing

The manufacturing sector is witnessing the emergence of specialized roles that blend technological expertise with industry-specific knowledge. Robotics integration specialists, industrial data analysts, and sustainable manufacturing engineers are becoming increasingly critical in contemporary industrial landscapes. These roles demand a holistic understanding of technological ecosystems, requiring professionals to continuously adapt and learn. They must navigate complex interdisciplinary environments, understanding how technological innovations can drive operational efficiency, sustainability, and competitive advantage.Skills and Educational Pathways for Future Manufacturing Professionals

Successful manufacturing professionals in 2025 will require a multifaceted skill set that transcends traditional educational boundaries. Technical proficiency must be complemented by adaptability, critical thinking, and continuous learning capabilities. Educational institutions are responding by developing integrated curricula that combine technical training with broader technological understanding. Interdisciplinary programs, industry partnerships, and experiential learning opportunities are becoming crucial in preparing the next generation of manufacturing professionals.Global Perspectives and Technological Innovation

The manufacturing job market is increasingly global, with technological innovations creating interconnected professional ecosystems. Professionals must develop cross-cultural communication skills, understanding how technological solutions can be adapted across diverse industrial contexts. International collaboration, remote work capabilities, and a global perspective are becoming essential competencies. Manufacturing professionals are no longer confined by geographical boundaries but are part of a dynamic, interconnected global workforce driving technological innovation.RELATED NEWS

Manufacturing

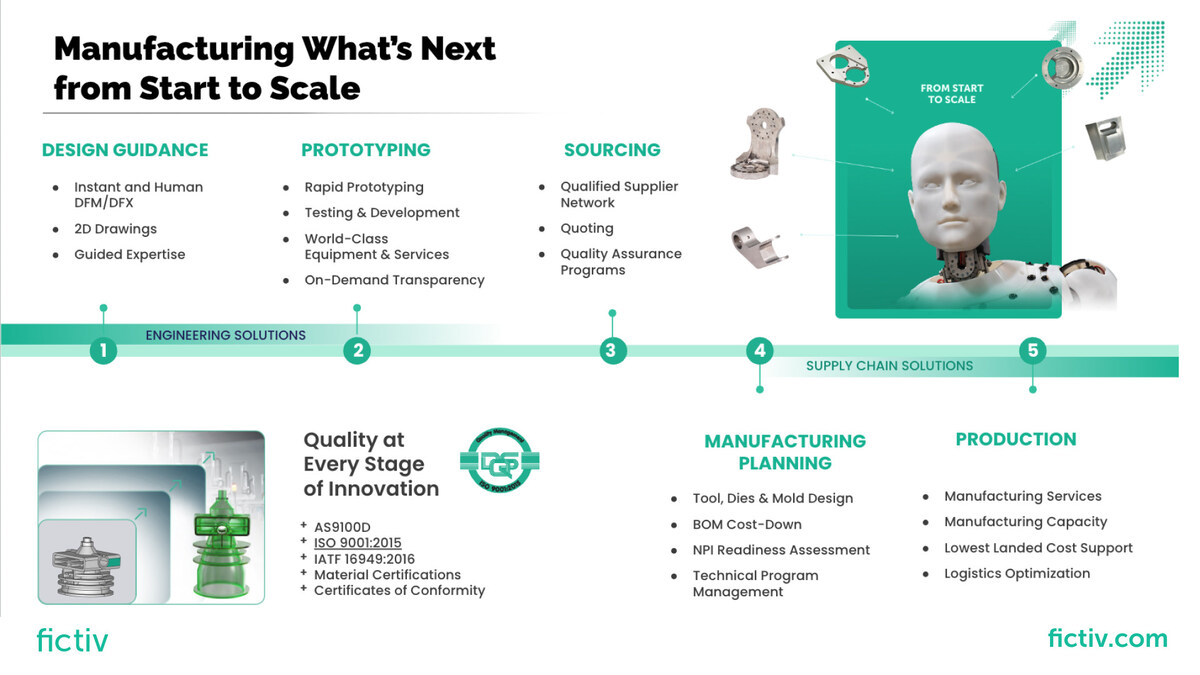

Breaking: Fictiv Unveils Game-Changing Manufacturing Strategy to Outsmart Global Trade Tensions

2025-03-26 13:00:00

Manufacturing

Aerowerks Launches Groundbreaking Manufacturing Facility in Cherokee County

2025-05-05 11:44:20

Manufacturing

Factory Floor Alarm: U.S. Manufacturing Hits Unexpected Downturn in 2023

2025-04-01 14:00:00