Silicon Valley's Manufacturing Dreams Collide with the Harsh Reality of Technological Economics

Manufacturing

2025-03-24 11:04:34Content

Introducing Tech In Depth: Your Daily Tech Business Insider

Welcome to the reimagined Tech In Depth, a dynamic daily newsletter that brings you cutting-edge reporting and insightful analysis from Bloomberg's global network of tech journalists. Today, we dive deep with Drake Bennett, exploring the complex challenges facing the ambitious mission of reshoring electronics manufacturing back to the United States.

In this compelling exploration, Bennett uncovers the practical hurdles that make the dream of revitalizing domestic electronics production more complicated than many might imagine. Our in-depth coverage provides a nuanced look at the economic, logistical, and strategic obstacles standing in the way of bringing high-tech manufacturing back to American soil.

Stay tuned for an illuminating journey through the intricate world of tech manufacturing, where innovation meets real-world constraints.

The Challenging Odyssey of Reshoring: America's Electronics Manufacturing Renaissance

In the complex landscape of global industrial strategy, the United States stands at a critical crossroads, contemplating a transformative journey to reclaim its manufacturing prowess and reduce dependency on international supply chains, particularly in the high-stakes realm of electronics production.Navigating the Intricate Maze of Domestic Manufacturing Revival

The Economic Complexity of Reshoring Electronics

The ambitious endeavor to repatriate electronics manufacturing represents far more than a simple economic pivot. It encompasses a multifaceted challenge that intertwines technological infrastructure, workforce development, financial investment, and geopolitical strategy. Unlike simplistic narratives suggesting immediate feasibility, the reality reveals a labyrinthine process fraught with substantial obstacles. Manufacturers confronting this herculean task must navigate a terrain marked by significant structural impediments. The existing global electronics manufacturing ecosystem has been meticulously constructed over decades, with Asian economies like China and Taiwan developing sophisticated, integrated supply networks that offer unprecedented efficiency and cost-effectiveness.Technological Infrastructure and Skill Gaps

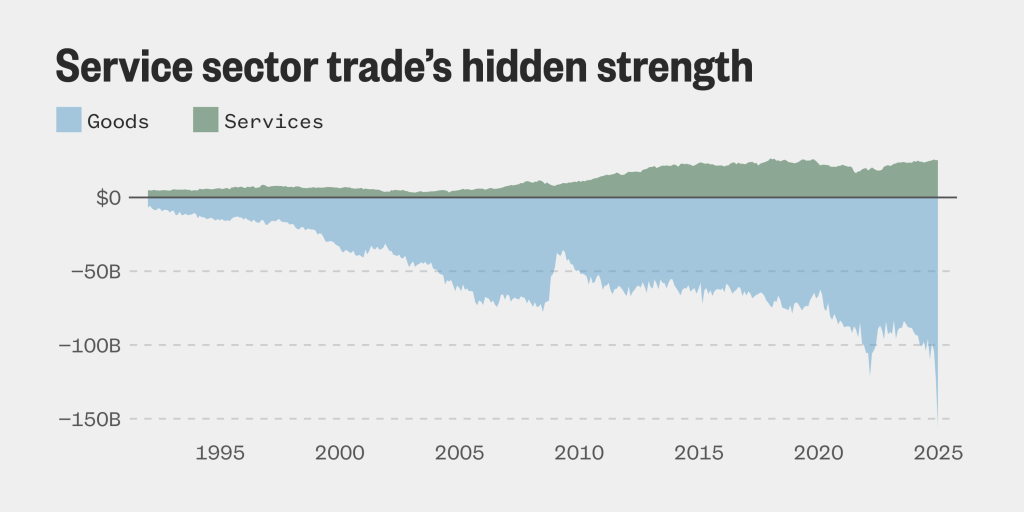

Rebuilding domestic electronics manufacturing requires more than financial commitment; it demands a comprehensive reimagining of technological capabilities. The United States currently lags behind in critical areas of semiconductor fabrication and advanced manufacturing techniques, necessitating massive investments in research, development, and specialized workforce training. The skill gap represents a profound challenge. Decades of outsourcing have eroded the specialized knowledge and technical expertise once prevalent in American manufacturing sectors. Reconstructing this intellectual infrastructure demands long-term strategic planning, substantial educational investments, and collaborative efforts between industry, academic institutions, and government agencies.Economic Barriers and Global Competition

Economic realities present formidable challenges to reshoring initiatives. The cost differential between domestic and international manufacturing remains significant, with labor and operational expenses in the United States substantially higher than in traditional manufacturing hubs. Companies must carefully evaluate the financial implications of reshoring, balancing potential strategic advantages against immediate economic constraints. Moreover, global competitors continue to innovate and optimize their manufacturing processes, creating a moving target for domestic reconstruction efforts. The dynamic nature of international industrial ecosystems requires continuous adaptation and strategic agility.Geopolitical Considerations and Strategic Resilience

Beyond pure economic calculations, reshoring electronics manufacturing carries profound geopolitical implications. The COVID-19 pandemic and ongoing international tensions have exposed the vulnerabilities of hyper-globalized supply chains, compelling nations to reconsider strategic industrial policies. The United States must develop a nuanced approach that balances economic efficiency with national security imperatives. This requires creating robust, flexible manufacturing capabilities that can withstand potential global disruptions while maintaining competitive technological standards.Innovative Pathways and Future Prospects

Despite considerable challenges, emerging technologies and innovative strategies offer promising avenues for revitalizing domestic electronics manufacturing. Advanced robotics, artificial intelligence, and sophisticated automation technologies could potentially mitigate traditional cost barriers and enhance production efficiency. Public-private partnerships, targeted government incentives, and strategic investments in research and development represent crucial mechanisms for supporting this complex transformation. By fostering an ecosystem of innovation and collaboration, the United States can gradually reconstruct its manufacturing capabilities. The journey of reshoring electronics manufacturing is not a straightforward trajectory but a sophisticated, multidimensional challenge requiring sustained commitment, strategic vision, and adaptive capabilities.RELATED NEWS

Manufacturing

Metal Meets Mind: The Rise of Humanoid Workers Transforming Factory Floors

2025-04-08 08:00:00

Manufacturing

Rebuilding American Manufacturing: CEOs Reveal the Slow, Strategic Path to Industrial Revival

2025-04-17 17:50:17