Breaking: UCF Leads Groundbreaking Initiative to Revolutionize Semiconductor Production

Manufacturing

2025-03-05 15:43:05Content

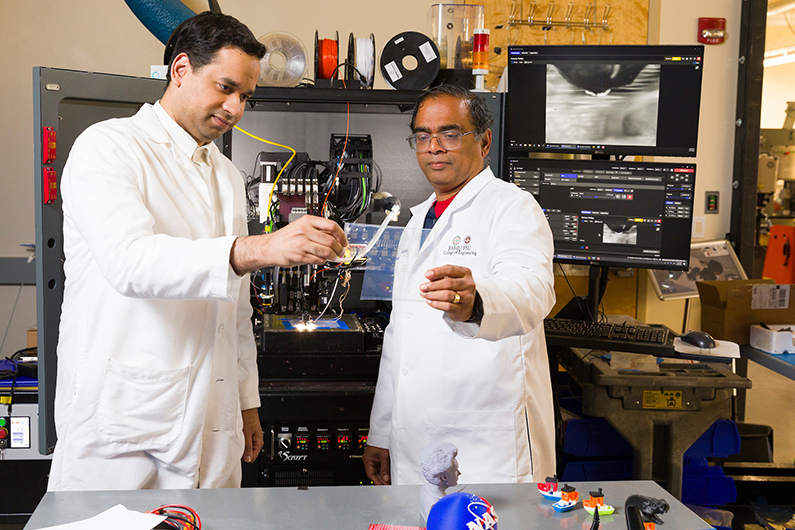

In a groundbreaking collaboration, the university is set to become a key contributor to an innovative regional research hub focused on advancing semiconductor chip manufacturing through cutting-edge digital twin technology. This strategic partnership promises to revolutionize the semiconductor industry by leveraging sophisticated digital simulation and modeling techniques.

The research hub aims to develop sophisticated digital replicas of semiconductor manufacturing processes, enabling engineers and researchers to optimize production, predict potential challenges, and enhance overall chip performance. By creating virtual representations that mirror real-world manufacturing environments, the project will provide unprecedented insights into complex semiconductor production workflows.

Through this initiative, the university will bring its expertise in advanced computational modeling and technological innovation to the forefront of semiconductor research. The digital twin technology is expected to significantly improve manufacturing efficiency, reduce production costs, and accelerate the development of more advanced and reliable semiconductor chips.

This collaborative effort represents a significant step forward in bridging academic research with industrial technological advancement, positioning the region as a potential leader in next-generation semiconductor manufacturing technologies.

Revolutionizing Semiconductor Manufacturing: UCF Leads Digital Twin Technology Breakthrough

In the rapidly evolving landscape of technological innovation, universities are increasingly becoming pivotal players in groundbreaking research initiatives that promise to reshape industrial manufacturing processes. The convergence of advanced computational technologies and semiconductor engineering represents a critical frontier of scientific exploration, with potential implications that could dramatically transform global technology production.Pioneering the Future of Precision Manufacturing

The Digital Twin Revolution in Semiconductor Engineering

Digital twin technology represents a quantum leap in manufacturing simulation and optimization, offering unprecedented insights into complex production processes. By creating virtual replicas of physical manufacturing systems, researchers can simulate, predict, and optimize semiconductor chip production with extraordinary precision. This innovative approach allows engineers to model intricate manufacturing environments, identifying potential inefficiencies and performance bottlenecks before they manifest in actual production lines. The computational complexity of digital twin technology requires sophisticated modeling techniques that integrate real-time data streams, advanced machine learning algorithms, and high-performance computing infrastructure. Semiconductor manufacturers can leverage these virtual representations to conduct comprehensive scenario analyses, reducing development costs and accelerating innovation cycles.Collaborative Research Ecosystem

The regional research hub represents a strategic collaboration between academic institutions, technology companies, and industrial partners. By pooling intellectual resources and technological capabilities, this consortium aims to push the boundaries of semiconductor manufacturing technologies. Universities like UCF play a crucial role in bridging theoretical research with practical industrial applications, creating a dynamic knowledge exchange platform. Interdisciplinary teams comprising computer scientists, electrical engineers, materials researchers, and data analytics experts will work collaboratively to develop sophisticated digital twin frameworks. These frameworks will not only enhance current manufacturing processes but also lay the groundwork for next-generation semiconductor technologies.Technological Implications and Global Competitiveness

The development of advanced digital twin technologies carries profound implications for global technological competitiveness. As semiconductor chips become increasingly critical in emerging technologies like artificial intelligence, quantum computing, and advanced robotics, nations and institutions that lead in manufacturing innovation will gain significant strategic advantages. By investing in cutting-edge research infrastructure and fostering collaborative research environments, universities like UCF are positioning themselves at the forefront of technological innovation. The ability to simulate and optimize semiconductor manufacturing processes with unprecedented accuracy could potentially reduce production costs, minimize material waste, and accelerate technological development cycles.Future Research Trajectories

The current research initiative represents more than a singular technological advancement; it signals a broader transformation in how complex manufacturing processes are conceptualized and executed. Future research will likely explore increasingly sophisticated simulation techniques, integrating artificial intelligence and machine learning to create even more dynamic and responsive digital twin models. Researchers anticipate that these technological developments will extend beyond semiconductor manufacturing, potentially revolutionizing production methodologies across multiple industrial sectors. The computational frameworks being developed could serve as foundational models for advanced manufacturing technologies in aerospace, automotive, and medical device industries.RELATED NEWS

Manufacturing

Pharma Giant Eli Lilly Unleashes $27 Billion Manufacturing Expansion: Four New Sites Set to Revolutionize Production

2025-02-26 17:37:02

Manufacturing

Breaking Barriers: How New Executive Orders Are Reshaping Workplace Diversity

2025-02-25 16:18:19