Precision Machines: How Measurement Science is Revolutionizing Robotic Manufacturing

Manufacturing

2025-03-07 11:51:57Content

In the intricate world of modern manufacturing, metrology stands as a silent guardian of precision, ensuring that every component meets exacting standards. Despite its critical importance, the integration of metrology within automated robot cells has historically been an underappreciated aspect of industrial innovation.

Precision is the lifeblood of advanced manufacturing, and metrology provides the essential measurements and quality control that transform raw processes into engineering excellence. Automated robot cells represent the cutting edge of manufacturing technology, yet they have often overlooked the nuanced role of precise measurement techniques.

Today, forward-thinking manufacturers are recognizing the transformative potential of seamlessly blending metrology with robotic automation. By embedding sophisticated measurement systems directly into robot cells, companies can achieve unprecedented levels of quality control, reducing errors and maximizing production efficiency.

The future of manufacturing lies not just in automation, but in intelligent, data-driven precision. Metrology is no longer a peripheral function but a core strategic element that drives innovation, reduces waste, and ensures consistently superior product quality across complex manufacturing environments.

Revolutionizing Manufacturing: The Precision Symphony of Robotic Metrology

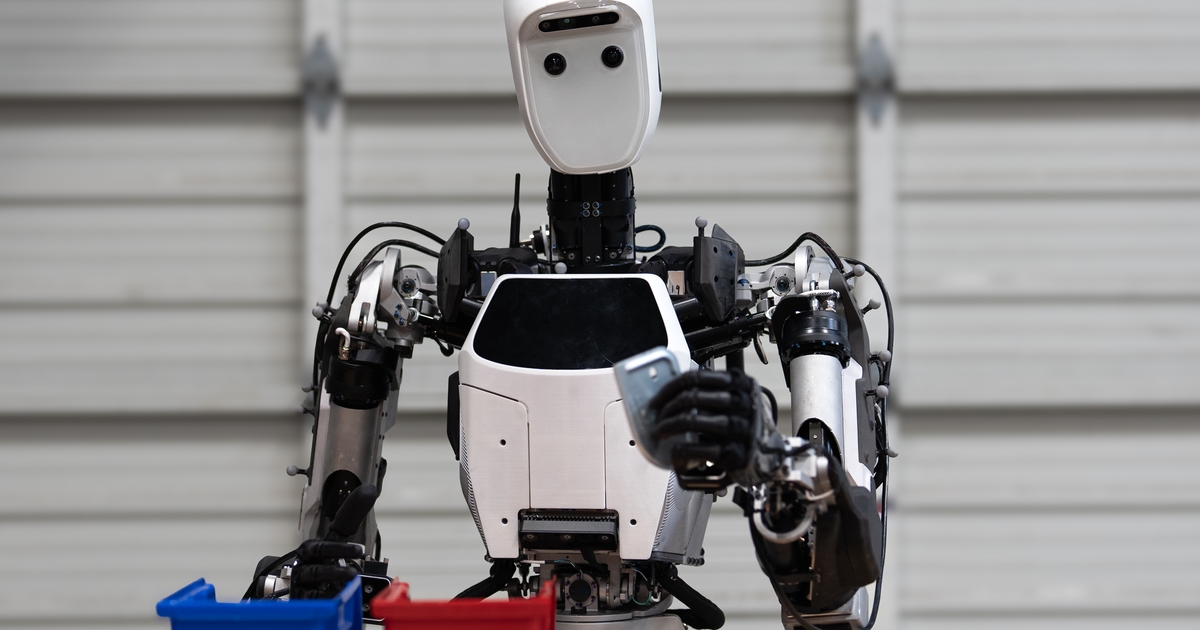

In the intricate world of modern manufacturing, a silent revolution is transforming how precision and automation intersect. The convergence of advanced metrology techniques with robotic systems represents a quantum leap in industrial precision, challenging traditional boundaries of measurement and technological integration.Precision Redefined: Where Technology Meets Measurement Mastery

The Metrology Metamorphosis in Automated Manufacturing

The landscape of industrial measurement is undergoing a profound transformation. Traditional metrology approaches are being systematically reimagined, with robotic systems emerging as powerful conduits of unprecedented precision. Advanced sensor technologies and sophisticated algorithmic frameworks are enabling machines to capture microscopic details with breathtaking accuracy, fundamentally reshaping our understanding of measurement capabilities. Manufacturers are discovering that integrating metrology directly into robotic workflows isn't just an incremental improvement—it's a paradigm shift. By embedding high-resolution measurement capabilities within automated cells, industries can achieve real-time quality control, dramatically reducing human error and enhancing overall production efficiency.Technological Convergence: Sensors, Robots, and Precision Engineering

Contemporary robotic metrology represents a sophisticated dance between cutting-edge hardware and intelligent software systems. Sophisticated optical sensors, laser scanning technologies, and advanced computational algorithms work in perfect synchronization, creating measurement ecosystems that can detect variations at nanometric scales. The integration process involves complex calibration protocols and advanced machine learning techniques. Robotic systems are now capable of self-calibration, continuously adjusting their measurement parameters to maintain exceptional accuracy. This dynamic adaptability ensures consistent performance across diverse manufacturing environments, from aerospace components to medical device production.Economic and Operational Implications of Advanced Metrology

The economic ramifications of integrated robotic metrology are profound. By eliminating manual measurement processes, manufacturers can significantly reduce labor costs, minimize human-induced errors, and accelerate production cycles. Each measurement becomes a data point in a larger quality management strategy, enabling predictive maintenance and continuous improvement methodologies. Industries ranging from automotive manufacturing to precision engineering are witnessing transformative outcomes. The ability to capture instantaneous, highly accurate measurements directly within production workflows represents a quantum leap in operational efficiency. Companies adopting these technologies are gaining substantial competitive advantages, reducing waste, and enhancing product consistency.Future Horizons: Emerging Trends in Robotic Measurement Technologies

The future of robotic metrology is incredibly promising. Emerging technologies like artificial intelligence, quantum sensing, and advanced machine learning are poised to further revolutionize measurement capabilities. Researchers are exploring novel approaches that could enable robots to not just measure, but predict and preemptively address potential manufacturing variations. Collaborative robots, or cobots, are increasingly being designed with integrated metrology capabilities. These intelligent systems can work alongside human operators, providing real-time feedback and ensuring quality standards are consistently met. The boundaries between measurement, production, and quality control are becoming increasingly blurred.Challenges and Opportunities in Implementation

Despite the immense potential, implementing advanced robotic metrology isn't without challenges. Significant investments in technology, training, and infrastructure are required. Organizations must develop comprehensive strategies that address technological, human, and organizational dimensions of this transformation. Successful implementation demands a holistic approach. It requires not just technological investment, but a cultural shift towards embracing data-driven precision and continuous innovation. Companies that can navigate these complexities will position themselves at the forefront of the next manufacturing revolution.RELATED NEWS

Manufacturing

Breaking Barriers: InstantGMP™ Unveils Spanish Portal to Empower Manufacturers Across Latin Markets

2025-02-24 11:00:00

Manufacturing

Revolutionizing Manufacturing: Polymer 3D Printing Set to Explode to $36 Billion Market by 2031

2025-03-28 14:15:00