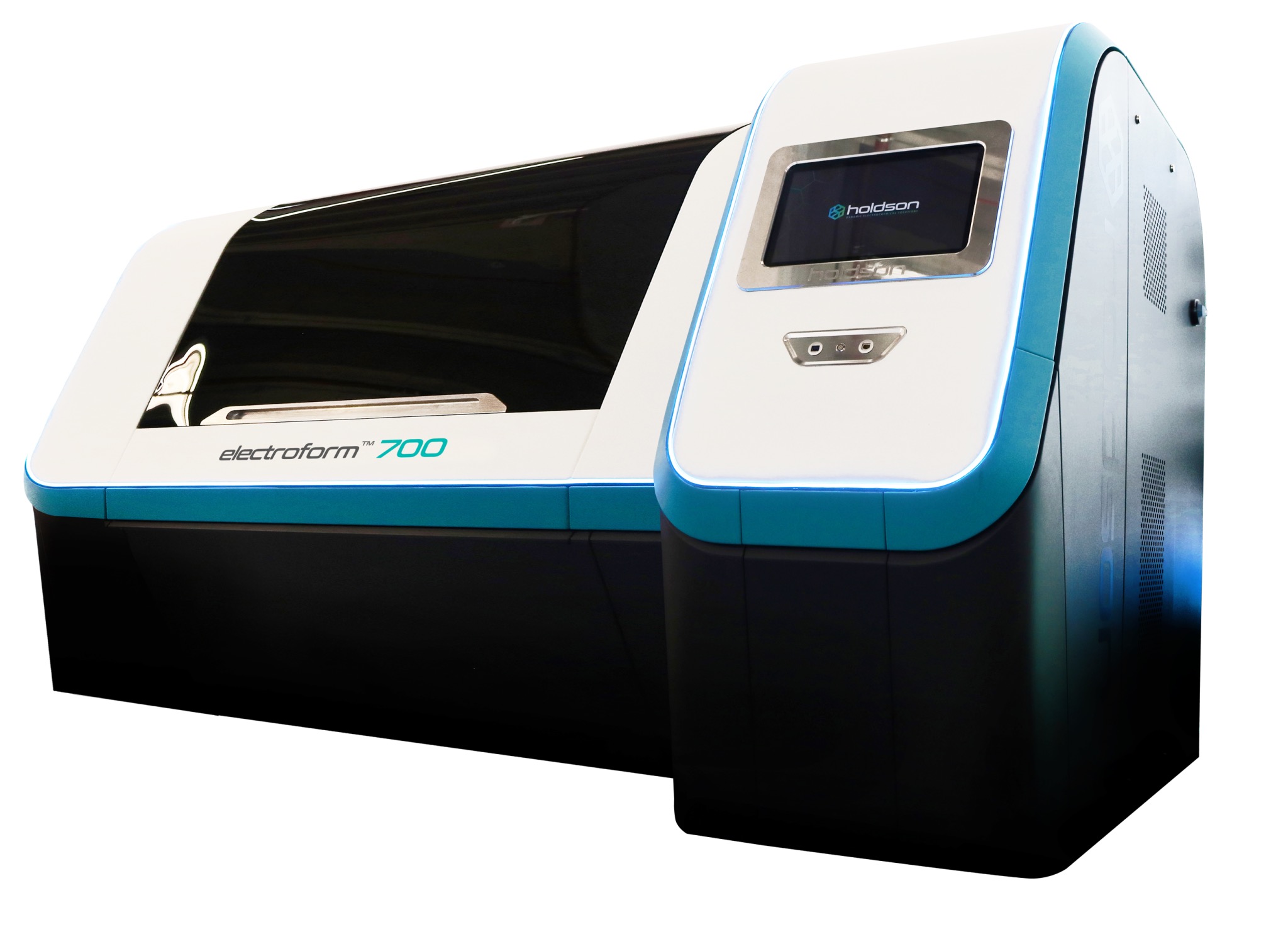

Revolutionizing 3D Printing: Additive Manufacturing Solutions Expands Capabilities with Holdson's Cutting-Edge Electroform Technology

Manufacturing

2025-04-03 08:53:02Content

Revolutionizing Surface Quality: Holdson and Additive Manufacturing Solutions Break New Ground

In the cutting-edge world of advanced manufacturing, Holdson and Additive Manufacturing Solutions are pushing the boundaries of surface technology through their groundbreaking electroform approach. This innovative technique represents a significant leap forward in precision engineering, offering unprecedented improvements in surface quality and performance.

By leveraging state-of-the-art electroforming technology, the collaboration between these industry leaders is transforming how manufacturers approach surface refinement. Their unique method allows for microscopic-level precision, creating surfaces with exceptional smoothness, durability, and structural integrity that were previously unimaginable.

The electroform process enables engineers to develop components with remarkable detail and consistency, opening up new possibilities across multiple industries, from aerospace and medical devices to high-performance electronics. By meticulously controlling the metal deposition process, Holdson and Additive Manufacturing Solutions are setting new standards in manufacturing excellence.

Professionals and engineers are taking notice of this revolutionary technique, recognizing its potential to dramatically enhance product performance and reliability. As manufacturing continues to evolve, this innovative approach promises to be a game-changer in surface engineering.

Revolutionizing Manufacturing: The Cutting-Edge Fusion of Electroform Technology and Additive Solutions

In the rapidly evolving landscape of advanced manufacturing, groundbreaking technologies are continuously reshaping how industries approach precision engineering and surface quality. The intersection of innovative techniques and sophisticated manufacturing processes represents a pivotal moment of technological transformation, where companies like Holdson and Additive Manufacturing Solutions are pushing the boundaries of what's possible in industrial production.Transforming Manufacturing Precision: Where Innovation Meets Excellence

The Electroform Revolution: Redefining Surface Engineering

Electroform technology emerges as a game-changing methodology that fundamentally reimagines surface quality and manufacturing precision. Unlike traditional manufacturing approaches, this sophisticated technique leverages electrochemical processes to create extraordinarily refined surface characteristics. Engineers and researchers have discovered that electroforming enables unprecedented levels of dimensional accuracy, allowing manufacturers to achieve microscopic tolerances that were previously unimaginable. The intricate process involves depositing metallic materials through controlled electrochemical reactions, creating surfaces with remarkable smoothness and structural integrity. By manipulating electrical currents and carefully selecting metallic compounds, technicians can generate components with near-perfect geometric specifications. This breakthrough represents a quantum leap in manufacturing capabilities, offering industries unprecedented opportunities for high-precision engineering.Advanced Manufacturing Techniques: Beyond Conventional Boundaries

Modern manufacturing demands solutions that transcend traditional limitations, and electroform technology stands at the forefront of this technological revolution. By integrating sophisticated computational modeling with precise electrochemical deposition, companies can now produce components with extraordinary complexity and refinement. The synergy between computational design and electrochemical processes enables manufacturers to create intricate structures with minimal material waste. Complex geometries that once seemed impossible can now be realized with remarkable efficiency. This approach not only reduces production costs but also minimizes environmental impact by optimizing material utilization and reducing energy consumption.Innovative Applications Across Multiple Industries

The potential applications of advanced electroform technology extend far beyond traditional manufacturing sectors. From aerospace engineering to medical device production, these sophisticated techniques are transforming how critical components are conceptualized and manufactured. Precision-critical industries such as semiconductor manufacturing, optical engineering, and advanced robotics are discovering unprecedented opportunities through these revolutionary techniques. Medical device manufacturers, for instance, can now create implants with microscopic surface textures that promote better biological integration. Aerospace engineers can develop lightweight yet incredibly strong components that withstand extreme environmental conditions. The versatility of electroform technology opens doors to innovations that were previously confined to theoretical discussions.Technological Synergies: Collaboration and Innovation

The collaboration between companies like Holdson and Additive Manufacturing Solutions exemplifies the power of interdisciplinary technological development. By combining expertise from different domains, these organizations are creating holistic solutions that address complex manufacturing challenges. Such collaborative approaches facilitate knowledge transfer, accelerate research and development, and ultimately drive technological progress. The cross-pollination of ideas and methodologies enables faster innovation cycles, allowing companies to respond more dynamically to emerging market demands and technological opportunities.Future Perspectives: The Next Frontier of Manufacturing

As electroform technology continues to evolve, we can anticipate even more sophisticated manufacturing techniques emerging. The integration of artificial intelligence, machine learning, and advanced materials science promises to unlock new dimensions of precision engineering. Researchers are already exploring nanotechnology applications that could further refine electroforming processes, potentially enabling manufacturing capabilities that currently exist only in the realm of scientific imagination. The ongoing convergence of computational power, material science, and electrochemical engineering suggests we are witnessing the early stages of a profound technological transformation.RELATED NEWS

Manufacturing

Inside Intel's Tech Revolution: New CEO's Bold Plan to Reshape Manufacturing and AI Landscape

2025-03-17 10:06:09

Manufacturing

Manufacturing Pulse: 5 Game-Changing Developments That Reshaped the Industry This Week

2025-02-28 14:59:36

Manufacturing

Driving Futures: ACCS and AAMA Launch Scholarships to Fuel Automotive Manufacturing Talent

2025-03-05 13:45:24