Industrial Alarm: South Korean Manufacturing Hits Lowest Point in Nearly Two Years

Manufacturing

2025-03-09 03:18:31Content

South Korea's manufacturing sector is grappling with its most significant downturn in over a year and a half, signaling potential challenges for the nation's industrial landscape. Recent economic data reveals a sharp contraction in industrial production, painting a concerning picture of the country's economic momentum.

The steep decline highlights mounting pressures on South Korea's manufacturing industry, which has long been a cornerstone of the nation's economic strength. Factors such as global supply chain disruptions, weakening international demand, and ongoing economic uncertainties appear to be contributing to this pronounced slowdown.

Economists are closely monitoring these developments, as the manufacturing sector's performance is often considered a critical barometer of broader economic health. The current situation suggests that South Korean industries may need to adapt quickly to changing market dynamics and global economic headwinds.

This unexpected contraction serves as a stark reminder of the fragility of industrial production in an increasingly complex global economic environment. Business leaders and policymakers will likely be examining strategies to reinvigorate the manufacturing sector and restore its previous resilience.

Manufacturing Meltdown: South Korea's Industrial Sector Faces Unprecedented Challenges

In the rapidly evolving landscape of global manufacturing, South Korea finds itself at a critical crossroads, grappling with an economic downturn that threatens to reshape its industrial prowess. The nation's manufacturing sector, long considered a cornerstone of its economic strength, is experiencing tremors that signal deeper structural challenges and potential systemic shifts in industrial productivity.When Industrial Titans Tremble: A Nation's Economic Resilience Tested

The Anatomy of Industrial Decline

The manufacturing landscape in South Korea has entered a period of unprecedented volatility, with output plummeting to levels not witnessed in nearly two years. This dramatic contraction represents more than a mere statistical anomaly; it reflects profound structural challenges confronting the nation's industrial ecosystem. Sophisticated economic indicators reveal a complex narrative of technological disruption, global supply chain recalibrations, and intensifying international competitive pressures. Economists and industry analysts are dissecting the multifaceted dimensions of this decline, identifying intricate interconnections between technological innovation, workforce dynamics, and global economic uncertainties. The manufacturing sector's current trajectory suggests a fundamental recalibration of industrial strategies, demanding innovative approaches to sustain competitiveness in an increasingly dynamic global marketplace.Technological Transformation and Economic Adaptation

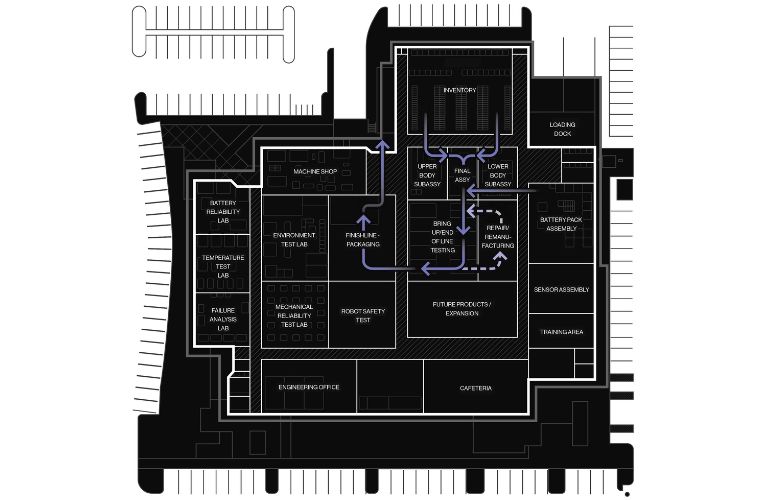

South Korea's manufacturing sector stands at a critical inflection point, requiring radical reimagination of traditional industrial paradigms. The current output decline is not merely a cyclical downturn but potentially signals a transformative moment demanding strategic reinvention. Advanced manufacturing technologies, artificial intelligence integration, and sustainable production methodologies are emerging as potential pathways to revitalize the industrial landscape. Emerging research indicates that companies embracing digital transformation and implementing sophisticated automation strategies are demonstrating greater resilience against market volatilities. The ability to rapidly adapt technological infrastructures and workforce capabilities will likely determine the survival and success of manufacturing enterprises in the coming decades.Global Economic Interconnectedness and Strategic Implications

The manufacturing output decline transcends national boundaries, reflecting intricate global economic interdependencies. International trade tensions, semiconductor supply chain disruptions, and geopolitical uncertainties have created a complex ecosystem challenging traditional manufacturing models. South Korean industries must navigate these turbulent waters with strategic agility and innovative problem-solving approaches. Sophisticated economic modeling suggests that nations capable of rapidly recalibrating their industrial strategies in response to emerging challenges will be best positioned to maintain competitive advantages. For South Korea, this means developing robust, flexible manufacturing ecosystems that can quickly adapt to technological and market transformations.Workforce Development and Future-Proofing Strategies

The current manufacturing challenges underscore the critical importance of continuous workforce skill development and technological education. South Korean educational and industrial training programs must evolve to equip workers with advanced technological competencies, ensuring they remain adaptable in an increasingly complex industrial landscape. Investments in human capital, particularly in areas of artificial intelligence, robotics, and advanced manufacturing technologies, will be paramount in reversing the current output decline. By creating a workforce capable of seamlessly integrating emerging technologies, South Korea can potentially reposition itself as a global leader in advanced manufacturing.Policy Interventions and Strategic Recommendations

Government and industrial leadership must collaborate to develop comprehensive strategies addressing the current manufacturing challenges. This requires a holistic approach encompassing technological investment, workforce training, and creating supportive regulatory environments that encourage innovation and industrial transformation. Targeted policy interventions, including financial incentives for technological modernization, research and development support, and strategic international collaborations, could provide the necessary momentum to revitalize South Korea's manufacturing sector. The path forward demands bold, visionary approaches that transcend traditional industrial paradigms.RELATED NEWS

Manufacturing

Revolutionary Tungsten Tech: How 3D Printing is Transforming Military Ammunition

2025-03-27 22:03:43

Manufacturing

Tariff Tides: How SourceDay Throws Manufacturing a Lifeline in Turbulent Trade Waters

2025-04-25 08:00:00

Manufacturing

Defense Tech Boom: Construct Capital Unleashes $300M War Chest for Industrial Innovation

2025-04-01 00:26:05