Breaking: Velo3D Supercharges Industrial 3D Printing with Game-Changing Production Tech

Manufacturing

2025-03-24 09:58:39Content

Velo3D Revolutionizes Metal 3D Printing with Innovative Rapid Production Solutions

In a groundbreaking move, Velo3D, a cutting-edge metal 3D printer manufacturer based in the United States, has unveiled its game-changing Rapid Production Solutions (RPS). This innovative platform is strategically designed to address the growing industry demand for scalable and high-precision metal manufacturing capabilities.

The new RPS technology is poised to transform production processes across critical sectors, with a particular focus on aerospace and other high-performance industries. By combining advanced 3D printing techniques with unprecedented manufacturing flexibility, Velo3D is setting a new standard for metal part production.

Engineered to meet the increasingly complex requirements of modern manufacturing, Rapid Production Solutions offers manufacturers an unprecedented opportunity to streamline their production workflows. The solution promises to deliver superior quality parts with remarkable consistency, enabling companies to push the boundaries of what's possible in metal component design and fabrication.

As industries continue to seek more efficient and adaptable manufacturing technologies, Velo3D's latest innovation represents a significant leap forward in metal 3D printing capabilities. The company's commitment to pushing technological boundaries is evident in this comprehensive production solution that addresses both scalability and precision.

Revolutionary Metal 3D Printing: Velo3D Transforms Manufacturing Landscape

In the rapidly evolving world of advanced manufacturing, technological innovations continue to reshape industrial production paradigms. Metal 3D printing represents a groundbreaking frontier that promises to revolutionize how complex components are designed, engineered, and manufactured across multiple high-stakes industries.Precision Engineering Meets Cutting-Edge Manufacturing Solutions

The Emergence of Advanced Metal Additive Manufacturing

Metal 3D printing has emerged as a transformative technology that challenges traditional manufacturing methodologies. Unlike conventional subtractive manufacturing processes, additive manufacturing enables engineers and designers to create intricate geometries with unprecedented precision and complexity. Velo3D's breakthrough Rapid Production Solutions (RPS) represents a quantum leap in this technological domain, offering manufacturers an integrated approach to producing high-performance metal components. The company's innovative platform transcends traditional limitations, providing unprecedented design flexibility and manufacturing capabilities. By leveraging advanced computational algorithms and state-of-the-art printing technologies, Velo3D enables engineers to push the boundaries of what's possible in metal component fabrication.Aerospace and Industrial Applications

The aerospace sector stands at the forefront of metal 3D printing adoption, where extreme performance requirements demand exceptional material properties and geometric complexity. Velo3D's solution addresses critical challenges faced by aerospace engineers, including weight reduction, structural integrity, and advanced thermal management. Sophisticated metal printing technologies allow for the creation of lightweight yet incredibly strong components that were previously impossible to manufacture using traditional methods. These innovations translate into significant performance improvements, reduced material waste, and enhanced overall efficiency in aerospace and related industrial applications.Technological Architecture of Rapid Production Solutions

Velo3D's technological ecosystem represents a holistic approach to metal additive manufacturing. The company's integrated solution encompasses advanced hardware, sophisticated software, and comprehensive process control mechanisms. By developing a fully synchronized platform, Velo3D eliminates many traditional barriers associated with metal 3D printing. The proprietary technology enables unprecedented levels of geometric complexity, allowing engineers to design components that optimize performance characteristics. Machine learning algorithms and real-time monitoring systems ensure consistent quality and repeatability, critical factors in high-precision manufacturing environments.Economic and Environmental Implications

Beyond technical capabilities, Velo3D's Rapid Production Solutions offer substantial economic and environmental benefits. By reducing material waste, minimizing energy consumption, and enabling more efficient production cycles, the technology contributes to more sustainable manufacturing practices. The ability to produce complex parts with fewer manufacturing steps translates into significant cost savings and reduced carbon footprint. This approach aligns with global sustainability goals while providing manufacturers with a competitive technological advantage.Future Trajectory of Metal 3D Printing

As industries continue to demand increasingly sophisticated manufacturing solutions, Velo3D's technological platform represents a glimpse into the future of production engineering. The convergence of advanced computational design, materials science, and precision manufacturing promises to unlock unprecedented possibilities across multiple sectors. Continuous research and development will likely expand the capabilities of metal 3D printing, potentially revolutionizing how we conceptualize, design, and produce complex mechanical components. Velo3D stands at the forefront of this technological transformation, driving innovation and pushing the boundaries of what's achievable in modern manufacturing.RELATED NEWS

Manufacturing

Manufacturing Momentum Stalls: How Trump's Shadow Looms Over Biden's Industrial Dream

2025-04-10 16:49:23

Manufacturing

Pharma Giant Lilly Unleashes $27 Billion Manufacturing Expansion Across America

2025-02-27 13:40:47

Manufacturing

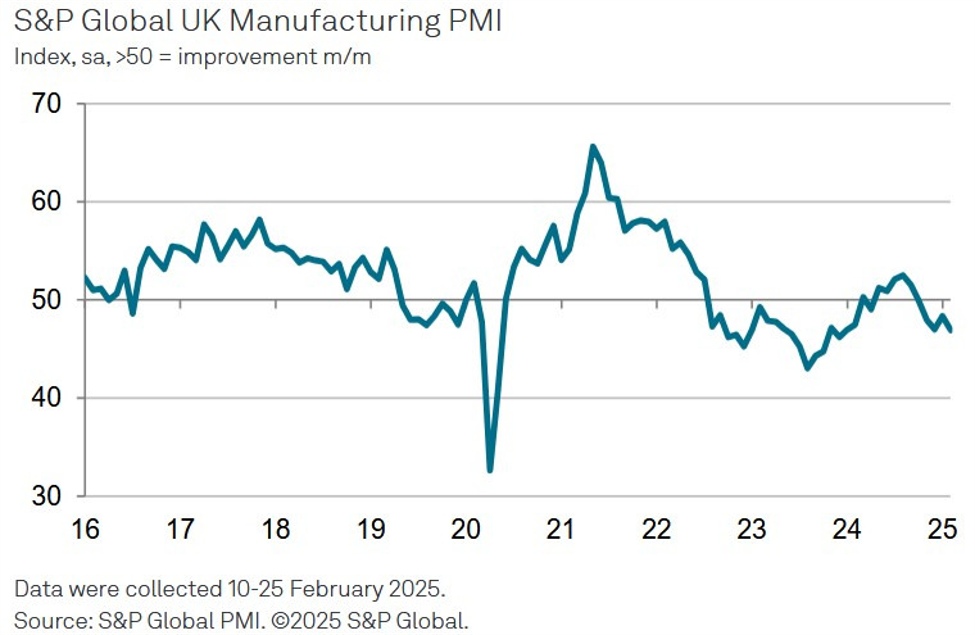

Manufacturing Sector Resilience: UK's February PMI Beats Preliminary Estimates

2025-03-03 09:30:04