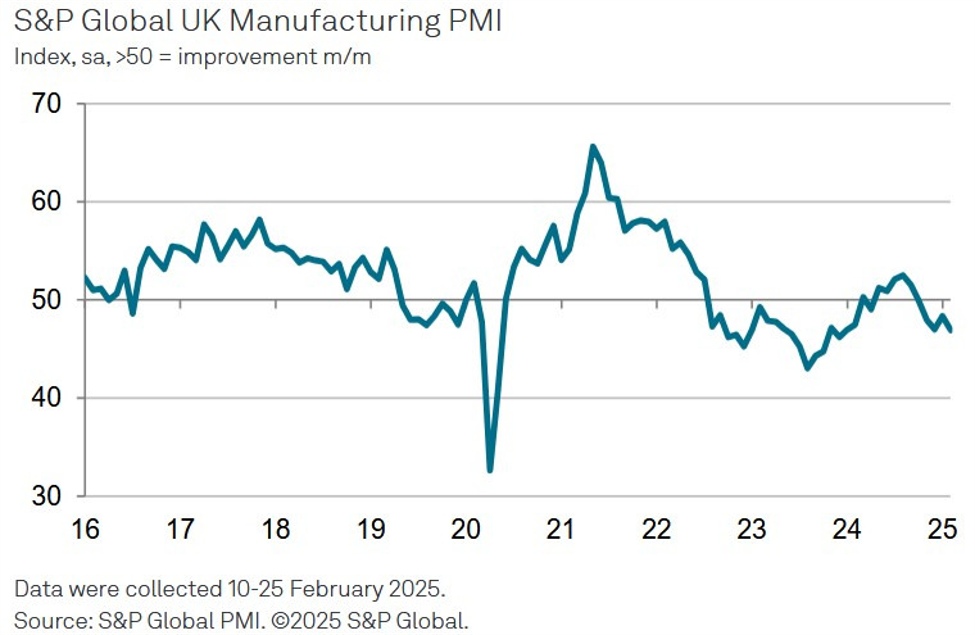

Manufacturing Sector Resilience: UK's February PMI Beats Preliminary Estimates

Manufacturing

2025-03-03 09:30:04Content

S&P Global Unveils Comprehensive Final Data Report for 2025

In a landmark release on March 3rd, 2025, S&P Global has published its definitive economic analysis, offering unprecedented insights into the global financial landscape. The comprehensive report provides a detailed breakdown of key economic indicators, market trends, and strategic forecasts that are set to shape the global economic narrative.

Analysts at S&P Global have meticulously compiled data from multiple sectors, presenting a nuanced view of economic performance and potential growth trajectories. The report highlights critical developments across international markets, offering stakeholders and investors a strategic overview of emerging opportunities and potential challenges.

Key highlights of the report include:

- Comprehensive market trend analysis

- Detailed economic performance metrics

- Forward-looking economic projections

- Sector-specific insights and recommendations

Investors, policymakers, and business leaders are encouraged to review this pivotal document to gain a deeper understanding of the current economic ecosystem and potential future developments.

Manufacturing Sector Trembles: Unveiling the Hidden Economic Signals in Global Production Dynamics

In the intricate landscape of global economic indicators, manufacturing performance emerges as a critical barometer measuring industrial health, economic resilience, and potential future trajectories. The latest data release from S&P Global provides a nuanced glimpse into the complex machinery of industrial production, revealing intricate patterns that extend far beyond mere statistical representations.Decoding Economic Momentum: Where Industry Meets Innovation

The Pulse of Global Manufacturing

The contemporary manufacturing ecosystem represents a sophisticated network of interconnected economic mechanisms, where technological innovation, geopolitical dynamics, and strategic investments converge to shape industrial landscapes. Recent analytical insights suggest a profound transformation occurring within global production systems, characterized by unprecedented technological integration and adaptive strategies. Emerging trends indicate that manufacturers are increasingly leveraging advanced technologies like artificial intelligence, machine learning, and predictive analytics to optimize operational efficiency. These technological interventions are not merely incremental improvements but represent fundamental restructuring of traditional manufacturing paradigms.Economic Resilience and Structural Adaptations

Economic resilience has become a paramount consideration for industrial sectors navigating increasingly volatile global environments. Manufacturers are developing sophisticated risk mitigation strategies, implementing flexible production models that can rapidly respond to disruptions, whether stemming from supply chain complications, geopolitical tensions, or unexpected market shifts. The contemporary manufacturing landscape demands unprecedented agility, with organizations continuously recalibrating their operational frameworks to maintain competitive advantages. This requires not just technological sophistication but also strategic foresight and organizational adaptability.Technological Convergence and Industry 4.0

The ongoing digital transformation represents a watershed moment for manufacturing, fundamentally reimagining production processes through technological convergence. Industry 4.0 principles are driving radical innovations, integrating cyber-physical systems, internet of things (IoT) technologies, and intelligent automation to create more responsive, efficient, and data-driven manufacturing environments. Sophisticated sensor networks, real-time monitoring systems, and predictive maintenance technologies are enabling manufacturers to transition from reactive to proactive operational models. These technological interventions are not just enhancing efficiency but fundamentally restructuring traditional industrial paradigms.Global Supply Chain Dynamics

Contemporary manufacturing cannot be understood in isolation from complex global supply chain ecosystems. Recent geopolitical developments, including trade tensions and pandemic-induced disruptions, have exposed vulnerabilities in traditional supply chain architectures, compelling organizations to develop more resilient, diversified, and technologically integrated networks. Manufacturers are increasingly adopting strategies like near-shoring, diversifying supplier bases, and implementing advanced risk management technologies to mitigate potential disruptions. These strategic adaptations represent a profound reimagining of global production networks.Sustainability and Ethical Manufacturing

Environmental considerations and sustainable practices are rapidly transitioning from peripheral concerns to central strategic imperatives. Modern manufacturers are integrating comprehensive sustainability frameworks, recognizing that ecological responsibility is not just an ethical obligation but a critical competitive differentiator. Advanced technologies are enabling more precise environmental monitoring, carbon footprint reduction, and circular economy principles. Manufacturers are developing innovative approaches to resource optimization, waste reduction, and sustainable production methodologies.Future Outlook and Strategic Implications

The manufacturing sector stands at a critical inflection point, characterized by unprecedented technological potential and complex economic challenges. Success will be determined by organizations' ability to seamlessly integrate technological innovation, strategic adaptability, and comprehensive understanding of evolving global dynamics. Continuous learning, technological investment, and holistic strategic thinking will be paramount in navigating the increasingly complex manufacturing landscape of the future.RELATED NEWS

Nvidia's Bold Strategy: Huang Navigates Trade Tensions with Resilience and Manufacturing Pivot

Solar Tech Fire Sale: Cutting-Edge Thin-Film Patents and Manufacturing Gear Up for Grabs