Inside Sanofi's Digital Revolution: How Data Mapping Is Transforming Manufacturing

Manufacturing

2025-03-20 00:50:10Content

.jpg)

Data Mapping: The Strategic Cornerstone of Sanofi's Digital Manufacturing Transformation

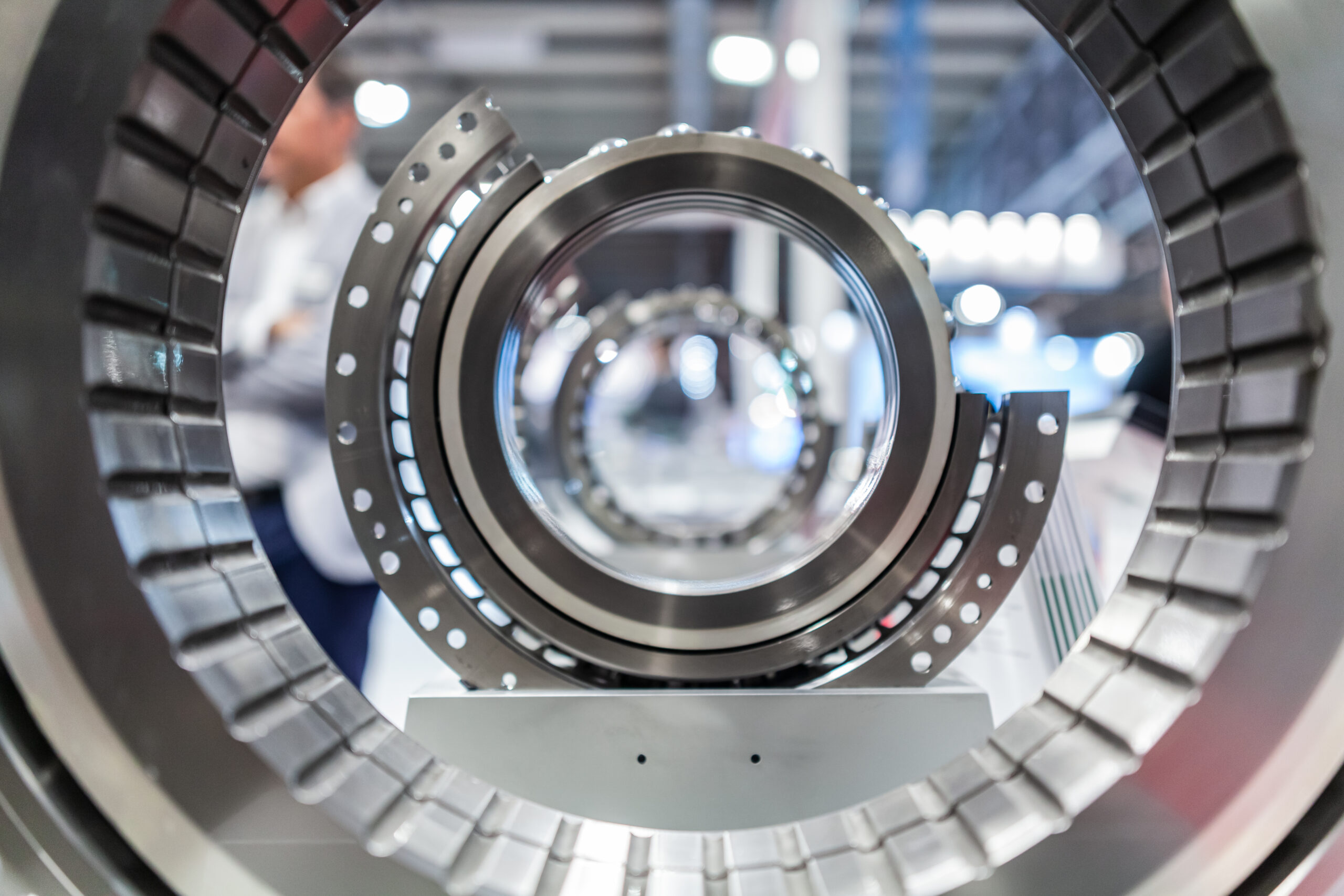

In the rapidly evolving landscape of biopharmaceutical manufacturing, Sanofi is pioneering a groundbreaking approach to digital transformation through strategic data mapping. This innovative methodology is not just a technological upgrade, but a comprehensive reimagining of how manufacturing networks can leverage data intelligence.

At the heart of Sanofi's digital strategy lies a sophisticated data mapping framework that seamlessly connects disparate manufacturing processes, creating an interconnected ecosystem of insights and operational efficiency. By meticulously tracking and integrating data across multiple production sites, the company is breaking down traditional silos and establishing a more agile, responsive manufacturing network.

The key objectives of this data mapping initiative include:

- Enhanced real-time visibility into manufacturing operations

- Improved predictive maintenance capabilities

- Streamlined quality control processes

- Accelerated decision-making through comprehensive data integration

By implementing this cutting-edge approach, Sanofi is not just digitizing its manufacturing processes, but fundamentally reimagining how pharmaceutical production can be optimized in the digital age. The data mapping strategy represents a bold step towards creating a more intelligent, responsive, and efficient biopharmaceutical manufacturing ecosystem.

Revolutionizing Biopharma: Sanofi's Digital Transformation Reshapes Manufacturing Landscape

In an era of unprecedented technological advancement, pharmaceutical giants are racing to reimagine their manufacturing ecosystems. Sanofi stands at the forefront of this digital revolution, implementing cutting-edge data mapping strategies that promise to redefine how biopharmaceutical networks operate in the 21st century.Navigating the Future: Where Technology Meets Pharmaceutical Innovation

The Digital Metamorphosis of Pharmaceutical Manufacturing

Pharmaceutical manufacturing has long been a complex, intricate process requiring precision and adaptability. Sanofi's groundbreaking approach represents a paradigm shift in how pharmaceutical networks conceptualize and implement technological integration. By leveraging advanced data mapping techniques, the company is creating a more responsive, intelligent manufacturing infrastructure that can rapidly adapt to changing global healthcare demands. The transformation goes beyond mere technological upgrade; it represents a holistic reimagining of manufacturing processes. Advanced algorithms and machine learning models are now being deployed to analyze intricate manufacturing workflows, identifying potential inefficiencies and optimizing production strategies in real-time. This approach allows for unprecedented levels of predictive maintenance and resource allocation.Strategic Data Integration and Intelligent Network Design

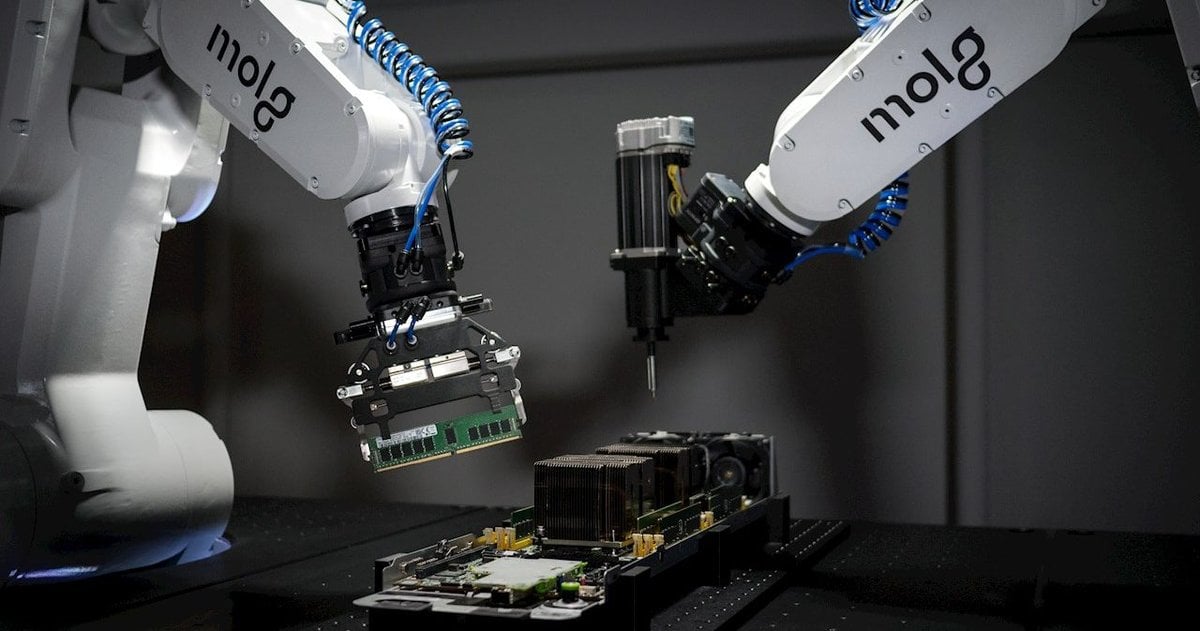

At the core of Sanofi's digital strategy lies a sophisticated data mapping framework that connects disparate manufacturing nodes into a cohesive, intelligent ecosystem. By implementing advanced interconnectivity protocols, the company can now monitor and manage production processes with remarkable granularity and precision. The data mapping approach enables real-time performance tracking, allowing immediate interventions and adjustments. Machine learning algorithms continuously analyze production data, identifying patterns and potential bottlenecks before they can impact overall manufacturing efficiency. This proactive approach represents a significant leap forward in pharmaceutical manufacturing management.Technological Infrastructure and Innovation Ecosystem

Sanofi's digital transformation is underpinned by a robust technological infrastructure that seamlessly integrates cutting-edge hardware and software solutions. Cloud computing, edge computing, and advanced analytics platforms work in concert to create a dynamic, responsive manufacturing network. The company has invested heavily in developing proprietary technologies that can handle the complex data streams generated by modern biopharmaceutical production processes. These technologies not only enhance operational efficiency but also provide unprecedented insights into manufacturing performance, quality control, and resource optimization.Global Impact and Future Implications

The implications of Sanofi's digital strategy extend far beyond the company's immediate manufacturing network. By demonstrating the potential of comprehensive digital transformation, Sanofi is setting new industry standards and challenging traditional pharmaceutical manufacturing paradigms. This approach has significant potential to accelerate drug development timelines, reduce production costs, and enhance overall product quality. The ability to rapidly adapt and optimize manufacturing processes could prove crucial in responding to global health challenges, from pandemic preparedness to personalized medicine development.Challenges and Continuous Evolution

Despite the promising outlook, Sanofi acknowledges that digital transformation is an ongoing journey. Continuous investment in technological research, employee training, and adaptive infrastructure will be critical to maintaining competitive advantage. The company remains committed to pushing technological boundaries and exploring emerging innovations in artificial intelligence, blockchain, and advanced analytics. The digital mapping strategy represents more than a technological upgrade—it's a fundamental reimagining of how pharmaceutical manufacturing can operate in an increasingly complex, interconnected global landscape.RELATED NEWS

Revving Up American Industry: Trump's Auto Tariffs Could Spark Manufacturing Renaissance

Manufacturing Titans Converge: Tennessee Chamber Sparks West TN Industrial Roundtable