Apple's Bold Move: U.S. iPhones Break Free from Chinese Production Lines

Manufacturing

2025-04-25 09:56:46Content

In a strategic shift that could reshape global manufacturing dynamics, Apple is set to dramatically reduce its reliance on Chinese production for iPhones by significantly expanding its manufacturing footprint in India. This bold move signals a major transformation in the tech giant's supply chain strategy, moving away from its traditional Chinese manufacturing base.

The decision comes amid escalating geopolitical tensions and a desire to diversify production risks. India, with its growing tech ecosystem and supportive government policies, has emerged as a compelling alternative to China's long-standing manufacturing dominance. Apple is now positioning India as a critical hub for iPhone production, potentially reducing its vulnerability to global trade uncertainties.

By accelerating its manufacturing investments in India, Apple aims to not only mitigate supply chain risks but also tap into the massive Indian market. The company has been gradually increasing its production capabilities in the country, with local manufacturers like Foxconn and Tata Group playing pivotal roles in this strategic realignment.

This transition represents more than just a logistical change; it's a significant geopolitical and economic statement. As Apple moves to decentralize its production, the move could potentially inspire other global tech companies to reconsider their manufacturing strategies and explore alternative production landscapes.

The shift promises multiple benefits: reduced dependency on a single manufacturing region, potential cost efficiencies, and alignment with India's "Make in India" initiative. For Apple, this could be a game-changing strategy that redefines its global manufacturing approach.

Apple's Strategic Pivot: Reshaping iPhone Manufacturing Beyond Chinese Borders

In an unprecedented move that signals a significant transformation in global technology supply chains, Apple is orchestrating a monumental shift in its iPhone production strategy, potentially redefining international manufacturing dynamics and geopolitical economic relationships.Navigating Global Manufacturing Challenges with Unprecedented Innovation

The Geopolitical Landscape of Technology Manufacturing

The contemporary technological ecosystem is experiencing a profound metamorphosis, with multinational corporations increasingly reassessing their manufacturing strategies in response to complex geopolitical tensions. Apple's decision to diversify its production landscape represents a strategic masterstroke that transcends traditional manufacturing paradigms. By progressively reducing dependence on Chinese manufacturing facilities, the technology giant is demonstrating remarkable adaptability and foresight. The intricate web of global trade relations has been fundamentally altered by escalating international tensions, economic uncertainties, and shifting diplomatic landscapes. Apple's calculated move towards Indian manufacturing facilities is not merely a logistical adjustment but a nuanced geopolitical strategy that reflects deep understanding of emerging economic opportunities.India's Emerging Role in Global Technology Production

India's technological infrastructure has undergone remarkable transformation in recent years, positioning itself as a compelling alternative to traditional manufacturing hubs. The country's robust ecosystem of skilled labor, progressive government policies, and rapidly evolving technological capabilities have created an attractive environment for sophisticated electronics manufacturing. The Indian government's strategic initiatives, such as the "Make in India" program, have systematically dismantled bureaucratic barriers and created incentive structures that attract global technology manufacturers. These comprehensive reforms have transformed India from a peripheral player to a central protagonist in the global manufacturing narrative.Economic and Strategic Implications of Manufacturing Relocation

Apple's strategic pivot carries profound economic implications that extend far beyond immediate production considerations. By diversifying manufacturing locations, the company mitigates potential supply chain disruptions, reduces geopolitical risks, and potentially achieves significant cost optimizations. The decision represents a sophisticated risk management approach, acknowledging the volatile nature of international trade relationships. By establishing robust manufacturing capabilities in multiple geographic locations, Apple creates a resilient and adaptable production ecosystem that can rapidly respond to emerging challenges and opportunities.Technological Innovation and Manufacturing Capabilities

The transition to Indian manufacturing is not merely a geographical relocation but a comprehensive technological transformation. Indian manufacturing facilities are increasingly adopting cutting-edge technologies, including advanced robotics, artificial intelligence-driven quality control mechanisms, and sophisticated supply chain management systems. These technological integrations ensure that iPhones manufactured in India meet the same rigorous quality standards expected from traditional manufacturing centers. The convergence of Indian technological expertise with Apple's stringent quality protocols promises a new era of global manufacturing excellence.Environmental and Social Sustainability Considerations

Beyond economic strategies, Apple's manufacturing diversification aligns with broader sustainability objectives. By expanding production capabilities in India, the company potentially contributes to local economic development, creates employment opportunities, and supports technological skill development in emerging markets. The move also reflects a growing corporate commitment to reducing carbon footprints by optimizing transportation logistics and leveraging more localized production ecosystems. This holistic approach demonstrates how strategic manufacturing decisions can simultaneously address economic, technological, and environmental challenges.RELATED NEWS

Manufacturing

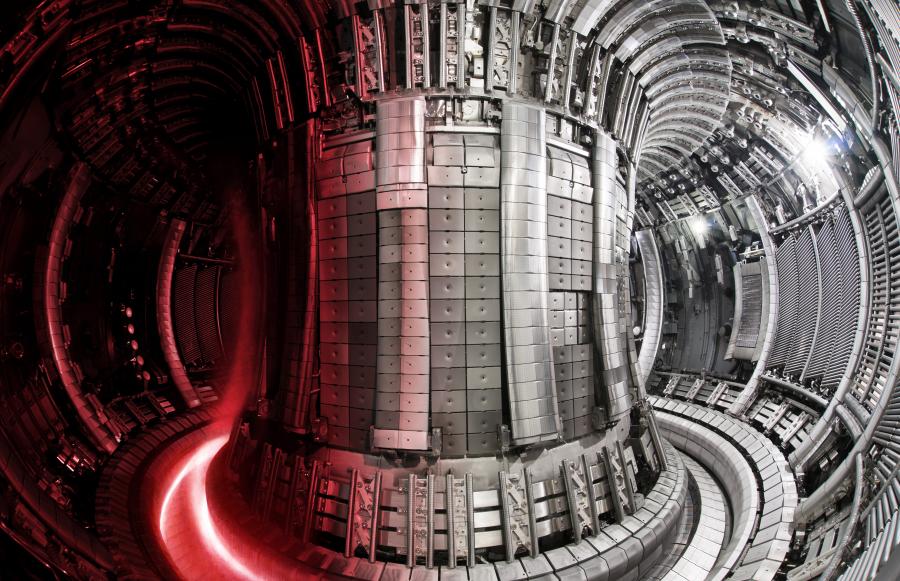

Cutting-Edge Fusion Tech: Freemelt Unlocks Advanced Tungsten Tile Production

2025-04-08 08:55:57

Manufacturing

Robots with Feelings: Inside the Emotional AI Revolution and Pharma's Latest Import Probe

2025-04-16 00:00:00

Manufacturing

Trade Showdown: Trump's Bold Tariff Gambit Threatens Global Economic Tensions

2025-04-02 20:13:24