Cutting-Edge Fusion Tech: Freemelt Unlocks Advanced Tungsten Tile Production

Manufacturing

2025-04-08 08:55:57Content

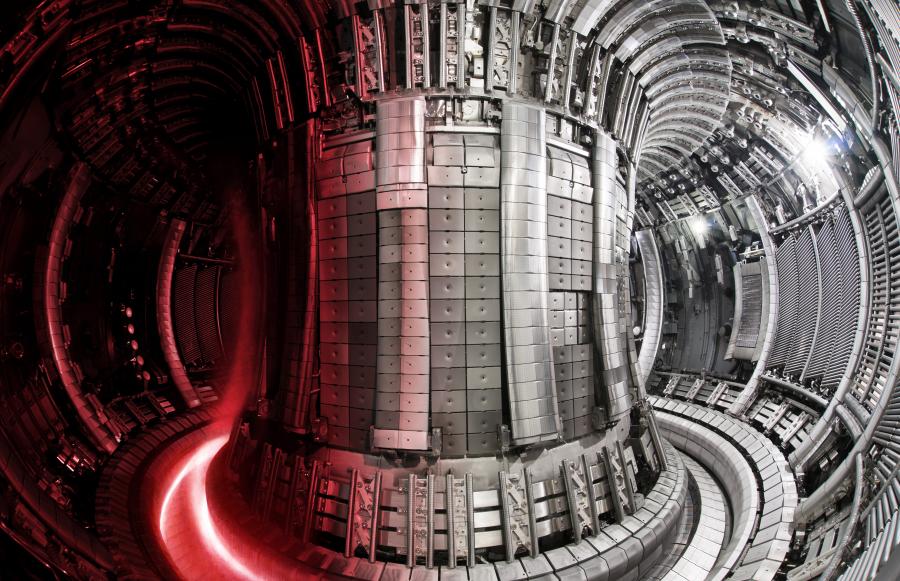

In a groundbreaking collaboration, Freemelt and F4E (Fusion for Energy) are joining forces to explore the potential of tungsten in advanced fusion energy technologies. The two organizations are conducting a comprehensive feasibility study aimed at qualifying tungsten as a critical material for future fusion reactor applications.

This strategic partnership represents a significant step forward in fusion energy research, focusing on understanding how tungsten can withstand the extreme conditions required in fusion reactor environments. By leveraging Freemelt's expertise in advanced manufacturing and F4E's deep knowledge of fusion technology, the study promises to unlock new possibilities for sustainable energy production.

The feasibility study will carefully examine tungsten's performance characteristics, structural integrity, and potential applications in high-temperature, high-stress fusion reactor components. Researchers hope to determine whether this robust metal can meet the demanding requirements of next-generation fusion energy systems.

As the global scientific community continues to pursue clean and virtually limitless energy solutions, collaborations like this between Freemelt and F4E highlight the innovative approaches being taken to overcome the complex challenges of fusion energy development.

Pioneering Plasma: Tungsten's Crucial Role in Next-Generation Fusion Energy Technology

In the rapidly evolving landscape of renewable energy research, groundbreaking collaborations are pushing the boundaries of scientific innovation. The intersection of advanced materials science and fusion energy technology represents a critical frontier in humanity's quest for sustainable power generation, with potential implications that could revolutionize global energy infrastructure.Unlocking the Future: Transformative Partnerships in Fusion Energy Research

The Strategic Alliance Between Freemelt and F4E

The collaborative endeavor between Freemelt and the European Fusion Development Agreement (F4E) marks a significant milestone in fusion energy research. This strategic partnership focuses on a comprehensive feasibility study aimed at qualifying tungsten as a critical material for advanced fusion energy applications. Tungsten's exceptional thermal and mechanical properties make it a prime candidate for withstanding the extreme conditions within fusion reactor environments. Fusion energy represents a transformative approach to power generation, mimicking the fundamental energy production mechanism of stars. By recreating the intense heat and pressure conditions that enable hydrogen atoms to fuse, scientists hope to develop a virtually limitless, clean energy source. The challenges of containing and managing such extreme conditions require materials of extraordinary resilience and performance.Material Science at the Cutting Edge

Tungsten emerges as a superhero material in this complex scientific narrative. Its remarkable ability to withstand temperatures exceeding 3,000 degrees Celsius and resist extreme neutron bombardment positions it as a potential game-changer in fusion reactor design. The Freemelt and F4E collaboration represents a meticulous exploration of tungsten's capabilities, employing advanced computational modeling and experimental techniques to validate its suitability. The research involves intricate analysis of tungsten's microstructure, examining how it responds to the intense plasma environments typical in fusion reactors. Advanced manufacturing techniques, including electron beam melting and precision metallurgical processes, enable researchers to create and test tungsten components with unprecedented precision and performance characteristics.Technological Implications and Global Impact

This feasibility study extends far beyond academic curiosity. Successfully qualifying tungsten could accelerate the development of commercially viable fusion energy systems, potentially providing a sustainable solution to global energy challenges. The implications are profound: a clean, safe, and virtually inexhaustible energy source that could dramatically reduce carbon emissions and mitigate climate change. The collaboration leverages cutting-edge computational simulations and experimental methodologies to push the boundaries of material science. By systematically evaluating tungsten's performance under simulated fusion reactor conditions, researchers aim to develop a comprehensive understanding of its potential and limitations.Interdisciplinary Innovation and Future Prospects

The partnership between Freemelt and F4E exemplifies the power of interdisciplinary collaboration. Materials scientists, plasma physicists, and engineering experts are converging to address one of humanity's most complex technological challenges. Their work represents a holistic approach to innovation, combining theoretical understanding with practical experimentation. As global energy demands continue to escalate and environmental concerns become increasingly urgent, research like this becomes not just scientifically interesting, but critically important. The potential of fusion energy to provide clean, safe, and abundant power could fundamentally reshape our approach to energy production and consumption.RELATED NEWS

Manufacturing

Chips, Challenges, and Competition: America's High-Stakes Silicon Showdown

2025-03-10 13:00:18

Manufacturing

Steel State Revival: VP Vance Heralds Manufacturing's Bright Future in South Carolina

2025-05-01 23:14:23

Manufacturing

Manufacturing's Resurgence: How Small Business Funding Is Rebuilding America's Industrial Backbone

2025-04-14 13:00:12