Breaking: Fictiv Unveils Game-Changing Manufacturing Strategy to Outsmart Global Trade Tensions

Manufacturing

2025-03-26 13:00:00Content

tags

3. Create a compelling title without outer quotes

Revolutionizing Manufacturing: Fictiv's Groundbreaking Supply Chain Transformation

In the rapidly evolving landscape of global manufacturing, technological innovation continues to reshape how businesses approach production, design, and supply chain management. Today's industrial ecosystem demands unprecedented agility, precision, and strategic integration that goes beyond traditional manufacturing paradigms.Unleashing Manufacturing Potential: Where Technology Meets Innovation

The Digital Manufacturing Revolution

Modern manufacturing is experiencing a profound metamorphosis driven by cutting-edge technological integrations. Companies like Fictiv are pioneering transformative approaches that fundamentally reimagine how complex products are conceptualized, designed, and brought to market. By leveraging advanced digital platforms, manufacturers can now transcend traditional limitations, creating more responsive, efficient, and adaptable production ecosystems. The convergence of artificial intelligence, machine learning, and sophisticated software platforms enables unprecedented levels of precision and customization. These technological breakthroughs allow businesses to dramatically reduce development cycles, minimize production risks, and optimize resource allocation with remarkable accuracy.Strategic Supply Chain Optimization

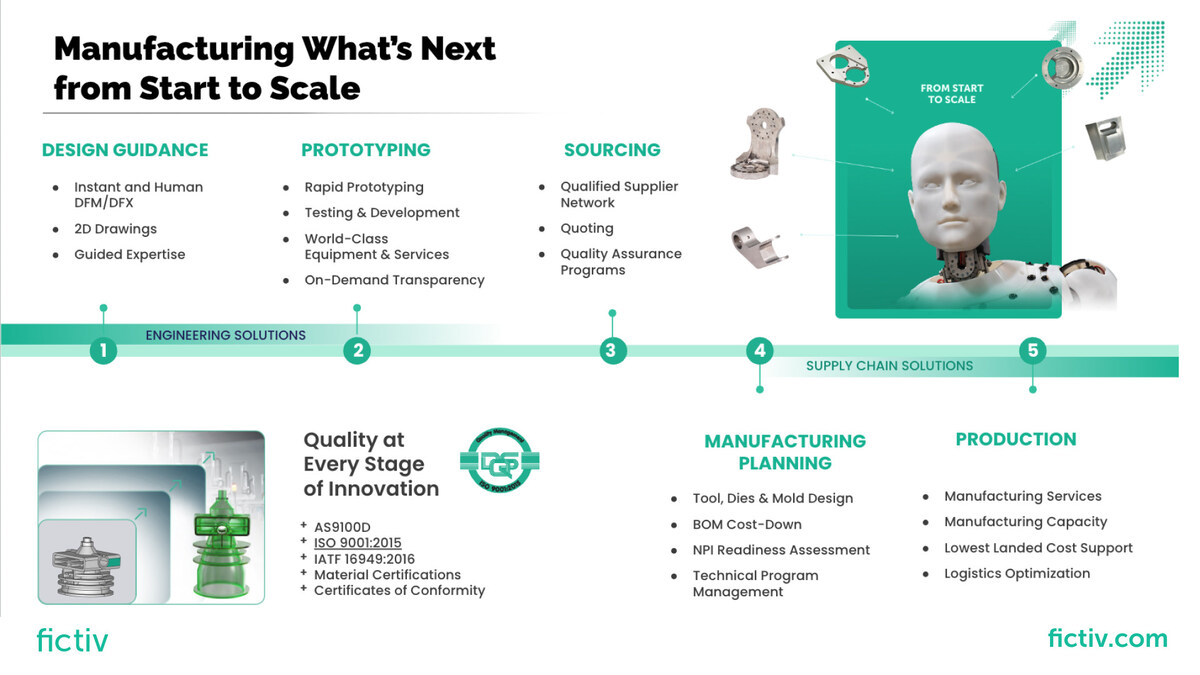

Contemporary supply chain management demands more than linear operational strategies. Fictiv's innovative approach represents a holistic reimagining of manufacturing workflows, integrating sophisticated digital tools that provide real-time insights, predictive analytics, and dynamic resource allocation mechanisms. By implementing advanced algorithmic frameworks, companies can now anticipate potential disruptions, streamline procurement processes, and create more resilient production networks. This approach transforms traditional supply chain models from reactive systems to proactive, intelligent ecosystems capable of adapting instantaneously to market fluctuations.Technological Integration and Collaborative Platforms

The future of manufacturing lies in collaborative, interconnected platforms that seamlessly bridge design, production, and distribution. Fictiv's expansion signals a critical shift towards more integrated, transparent, and efficient manufacturing methodologies. Digital platforms now enable unprecedented levels of collaboration, allowing engineers, designers, and production specialists to work synchronously across geographical boundaries. These technological innovations democratize manufacturing capabilities, providing smaller organizations access to sophisticated production resources previously available only to large-scale industrial players.Sustainable Manufacturing Practices

Beyond technological capabilities, modern manufacturing must prioritize sustainability and environmental consciousness. Fictiv's approach demonstrates a commitment to developing production strategies that minimize waste, optimize resource utilization, and reduce carbon footprints. By implementing intelligent design algorithms and leveraging advanced materials science, manufacturers can create more environmentally responsible production processes. This holistic approach considers not just immediate production requirements but long-term ecological implications of industrial activities.Future-Proofing Manufacturing Capabilities

As global markets become increasingly complex and unpredictable, organizations must develop adaptive manufacturing strategies. Fictiv's expansion represents more than a technological upgrade—it's a fundamental reimagining of how businesses approach production in an increasingly digital, interconnected world. The ability to rapidly prototype, iterate, and scale production becomes a critical competitive advantage. Companies that can quickly transform conceptual designs into market-ready products will lead their respective industries, driving innovation and setting new benchmarks for operational excellence.RELATED NEWS

Manufacturing

Tech Titan Microchip Slashes Workforce: 2,000 Jobs on the Chopping Block

2025-03-03 14:29:00

Manufacturing

Breaking: Asahi Kasei Revolutionizes Drug Production with Groundbreaking Oligonucleotide Manufacturing Breakthrough

2025-04-28 12:30:00

Manufacturing

Manufacturing Comeback: Trump's Bold Vision Hits Industrial Roadblocks

2025-04-10 12:00:36