Factory Floor Alarm: U.S. Manufacturing Hits Unexpected Downturn in 2023

Manufacturing

2025-04-01 14:00:00Content

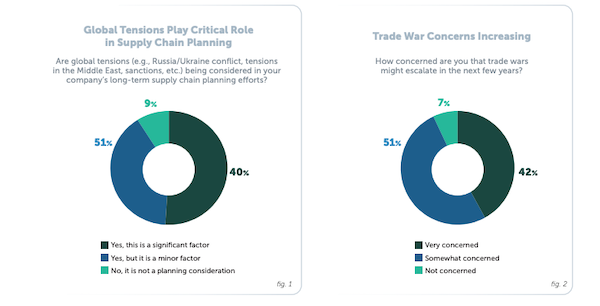

The U.S. manufacturing sector experienced a significant downturn in March, marking its first contraction of the year. The industry's challenges were further compounded by a sharp acceleration in prices, signaling the growing impact of escalating trade tensions and tariff pressures on the economic landscape.

As manufacturers grapple with increasing costs and uncertain market conditions, the latest economic indicators paint a complex picture of industrial activity. The sudden slowdown suggests that the ongoing trade disputes are beginning to take a tangible toll on American factory output, raising concerns about the broader economic implications.

Prices continued their upward trajectory for the second consecutive month, reflecting the mounting pressures from international trade conflicts and supply chain disruptions. This trend underscores the delicate balance manufacturers are trying to maintain in the face of mounting economic challenges.

Economic Tremors: The Unseen Impact of Tariffs on American Manufacturing

In the intricate landscape of global economic dynamics, manufacturing sectors often serve as the canary in the coal mine, signaling broader economic shifts and underlying tensions that reverberate through national and international markets.Decoding the Manufacturing Maze: When Tariffs Reshape Industrial Landscapes

The Manufacturing Contraction: A Deeper Economic Narrative

The American manufacturing sector has entered a critical phase of transformation, experiencing unprecedented challenges that extend far beyond simple statistical fluctuations. Recent economic indicators reveal a complex narrative of industrial recalibration, where traditional production models are being systematically disrupted by geopolitical tensions and trade policy interventions. Economists and industry analysts are closely examining the intricate mechanisms driving this contraction, recognizing that the current landscape represents more than a temporary economic hiccup. The interconnected nature of global supply chains means that even minor policy adjustments can trigger substantial ripple effects across multiple industrial ecosystems.Tariff Dynamics: Reshaping Economic Interactions

The implementation of escalating tariffs has created a multifaceted economic environment where manufacturers must continuously adapt and strategize. These trade barriers are not merely numerical adjustments but represent sophisticated geopolitical instruments that fundamentally alter competitive landscapes and strategic decision-making processes. Companies are now compelled to reevaluate their sourcing strategies, production methodologies, and long-term investment plans. The increased cost structures introduced by tariffs force businesses to make nuanced calculations about operational efficiency, potentially accelerating trends toward automation, localized production, and innovative supply chain redesigns.Price Acceleration: The Hidden Economic Mechanism

Beneath the surface of manufacturing metrics lies a complex pricing mechanism that reflects broader economic pressures. The acceleration of prices represents a sophisticated interplay between production costs, trade policies, and market expectations. Manufacturers are experiencing unprecedented challenges in maintaining stable pricing structures while navigating increasingly volatile economic terrain. This price dynamic extends beyond simple cost increases, representing a fundamental recalibration of value propositions across industrial sectors. Companies must now develop more agile pricing strategies that can rapidly respond to external economic stimuli while maintaining competitive positioning.Technological Adaptation and Industrial Resilience

The current manufacturing landscape demands unprecedented levels of technological integration and strategic flexibility. Forward-thinking organizations are leveraging advanced analytics, artificial intelligence, and predictive modeling to anticipate and mitigate potential economic disruptions. By developing robust technological infrastructures, manufacturers can transform potential challenges into opportunities for innovation and strategic repositioning. This approach requires a holistic understanding of technological ecosystems and the ability to rapidly implement transformative solutions.Global Context: Manufacturing in a Interconnected World

The American manufacturing sector does not exist in isolation but represents a critical node in a complex global economic network. The current contraction must be understood within a broader international context, where geopolitical tensions, technological advancements, and evolving trade relationships continuously reshape industrial landscapes. Understanding these intricate dynamics requires a multidisciplinary approach that combines economic analysis, technological insight, and strategic foresight. Manufacturers must develop comprehensive perspectives that transcend traditional industrial paradigms.RELATED NEWS

Manufacturing

Rocket Fuel for Growth: PBS Aerospace Pumps $20M into Cutting-Edge Roswell Plant

2025-03-03 00:35:17

Manufacturing

Aerospace Boom: Okaloosa Lands $16.8M Investment to Spark 300 New High-Tech Jobs

2025-04-02 00:20:44

Manufacturing

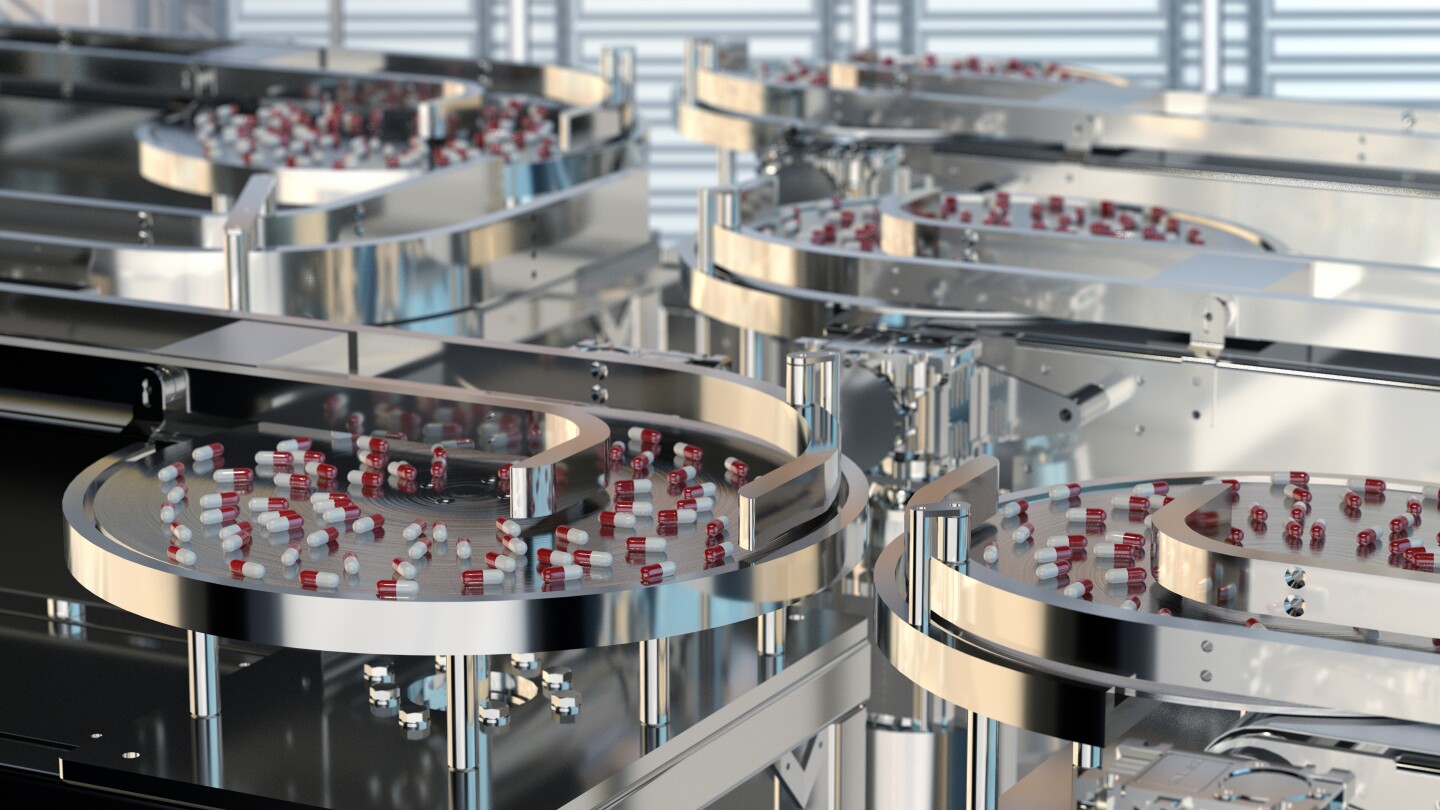

Breakthrough Weight-Loss Drug: Lilly Accelerates US Production After Landmark Clinical Success

2025-04-21 12:51:48