Trade Wars and Factory Floors: Can Tariffs Revive America's Manufacturing Might?

Manufacturing

2025-04-13 17:39:51Content

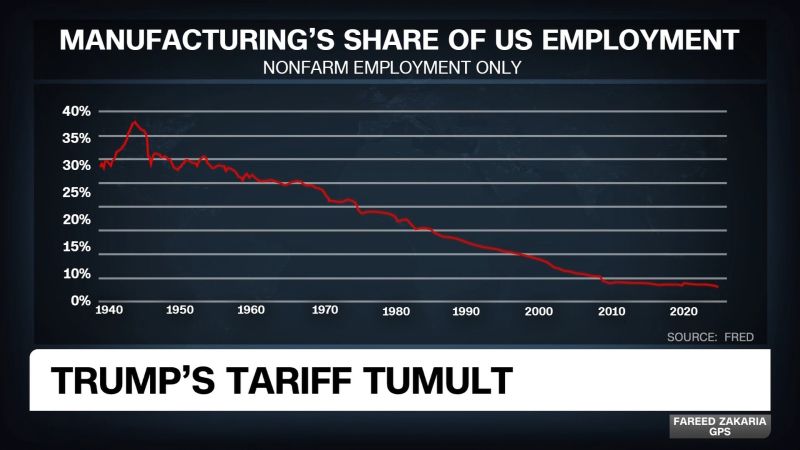

In the ongoing GPS debate, Fareed delves into a critical question that has been haunting American economic strategists: Can anything—even aggressive tariffs—truly revive domestic manufacturing? The once-thriving industrial landscape of the United States has undergone dramatic transformations, with global competition and outsourcing dramatically reshaping the manufacturing sector.

The potential for a manufacturing renaissance is complex, involving intricate economic, technological, and geopolitical factors. Tariffs, often touted as a potential solution, represent just one piece of a multifaceted puzzle. While protective trade policies might create short-term incentives for domestic production, sustainable revival requires a more comprehensive approach.

Experts suggest that successful reinvigoration of U.S. manufacturing will demand strategic investments in workforce training, advanced technologies, innovation ecosystems, and competitive infrastructure. The challenge isn't simply about bringing jobs back, but creating a robust, adaptable manufacturing environment that can compete on a global scale.

As the debate continues, the future of American manufacturing hangs in a delicate balance, with policymakers, business leaders, and economists searching for innovative strategies to reignite this critical economic engine.

The Manufacturing Renaissance: Can America Reclaim Its Industrial Throne?

In an era of global economic transformation, the United States stands at a critical crossroads, grappling with the complex challenge of revitalizing its manufacturing sector. The debate surrounding industrial resurgence has intensified, with policymakers, economists, and industry leaders passionately discussing strategies to bring production back to American soil.Unraveling the Complex Tapestry of Industrial Revival

The Global Economic Landscape and Manufacturing Dynamics

The contemporary manufacturing ecosystem represents a intricate web of global interconnectedness, challenging traditional economic paradigms. International trade agreements, technological advancements, and geopolitical tensions have fundamentally reshaped industrial production strategies. Multinational corporations now navigate a labyrinthine environment where cost-effectiveness, technological innovation, and strategic positioning intersect in unprecedented ways. Emerging economies have dramatically transformed manufacturing landscapes, offering competitive labor costs and sophisticated infrastructure. Countries like Vietnam, India, and Mexico have positioned themselves as attractive alternatives to traditional manufacturing powerhouses, creating significant challenges for American industrial resurgence.Tariffs: A Double-Edged Sword of Economic Policy

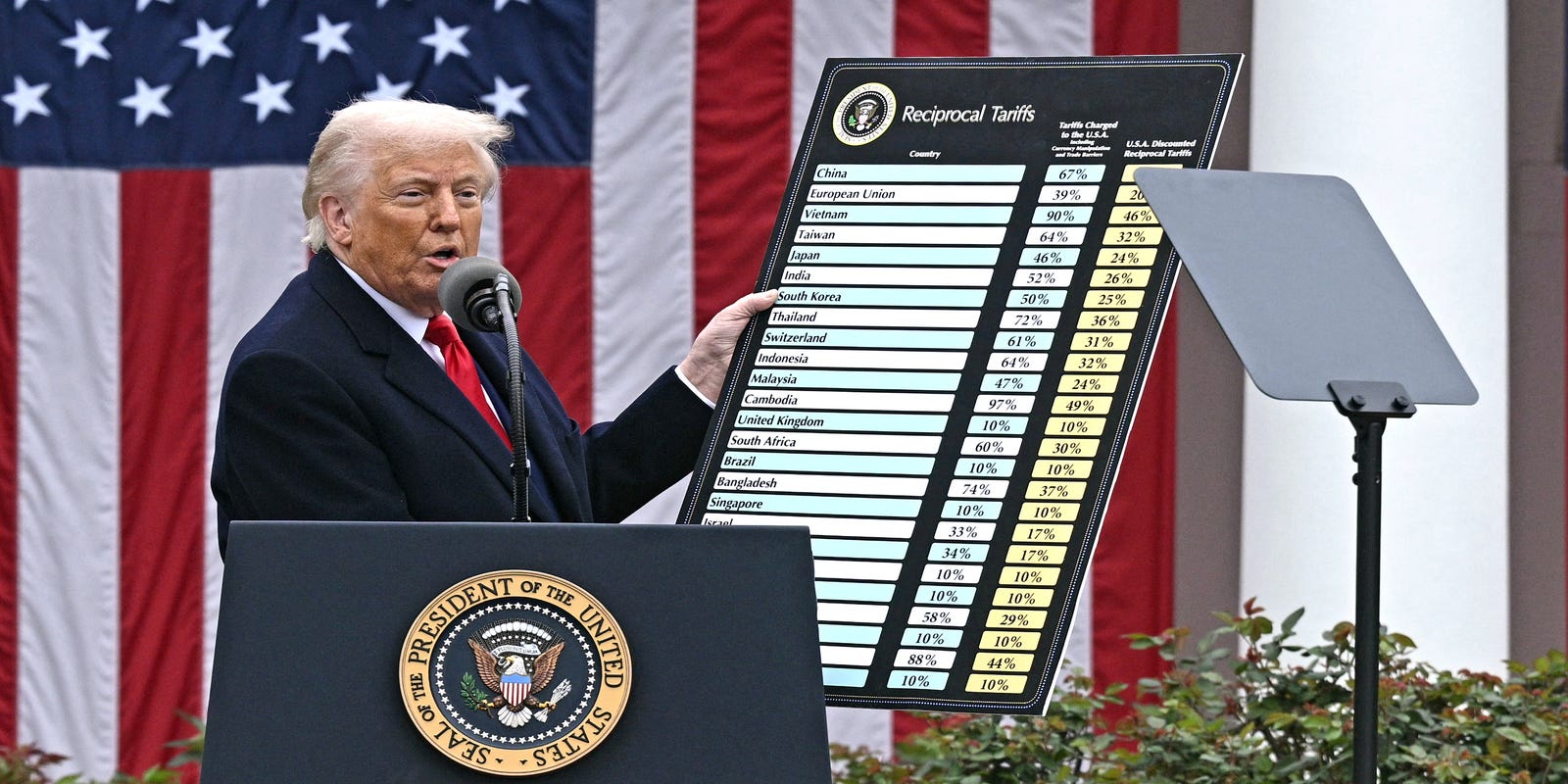

Tariff implementation emerges as a nuanced and controversial mechanism for potentially reinvigorating domestic manufacturing. While protectionist policies aim to create barriers against international competition, economists remain divided on their long-term effectiveness. Some argue that tariffs can provide temporary shelter for nascent industries, while others contend they ultimately harm consumer interests and broader economic growth. The intricate relationship between tariff structures and industrial competitiveness demands sophisticated analysis. Policymakers must balance immediate economic protection with long-term strategic development, considering complex factors like technological innovation, workforce skills, and global market dynamics.Technological Innovation: The True Manufacturing Catalyst

Technological advancement represents the most promising pathway for American manufacturing renaissance. Artificial intelligence, robotics, advanced manufacturing techniques, and digital transformation are redefining industrial capabilities. These technologies offer unprecedented opportunities for increasing productivity, reducing production costs, and creating high-value employment opportunities. The convergence of digital technologies with traditional manufacturing processes creates a revolutionary ecosystem. Smart factories, powered by interconnected systems and real-time data analytics, represent the future of industrial production. American companies that successfully integrate these technologies can potentially leapfrog international competitors.Workforce Development and Educational Transformation

Revitalizing manufacturing requires a holistic approach to workforce development. Educational institutions must collaborate closely with industry to create adaptive training programs that equip workers with cutting-edge technological skills. Community colleges, technical schools, and universities play crucial roles in bridging skill gaps and preparing a new generation of technologically proficient manufacturing professionals. Apprenticeship programs, public-private partnerships, and targeted skill development initiatives can help reconstruct the American manufacturing workforce. By investing in human capital and creating pathways for continuous learning, the United States can develop a resilient and innovative industrial ecosystem.Policy Frameworks and Strategic Investments

Comprehensive policy frameworks are essential for supporting manufacturing revival. Government incentives, research and development funding, and strategic infrastructure investments can create fertile ground for industrial growth. Policymakers must design nuanced approaches that balance economic protection with global competitiveness. Tax incentives, streamlined regulatory environments, and targeted support for emerging technologies can help create a conducive ecosystem for manufacturing innovation. By adopting a proactive and forward-thinking approach, the United States can position itself at the forefront of global industrial transformation.RELATED NEWS

Manufacturing

Manufacturing Milestone: Congresswoman McClain Delaney Tours Hagerstown's Cutting-Edge Plastics Facility

2025-04-15 23:32:55

Manufacturing

Reviving American Industry: Biden Team Backs Trump's Bold Tariff Strategy for Manufacturing Comeback

2025-04-12 11:27:29

Manufacturing

Manufacturing Renaissance: How Trump's Economic Strategies Revitalize Tennessee's Industrial Landscape

2025-04-26 11:00:41