Resilient Factories: How Manufacturing Titans Are Reinventing Themselves in Challenging Times

Manufacturing

2025-03-21 13:00:00Content

Lima's Industrial Backbone: Manufacturing Continues to Drive Local Economy

Manufacturing stands as a cornerstone of economic vitality in Lima and Allen County, serving as a powerful employment engine that sustains the region's workforce. With an impressive 19.3 percent of local workers employed in this robust sector, manufacturing remains a critical pillar of the area's economic landscape.

The manufacturing industry not only provides substantial employment opportunities but also represents a testament to the region's industrial strength and economic resilience. From precision engineering to advanced production techniques, Lima's manufacturers continue to demonstrate the community's commitment to innovation and economic growth.

These manufacturing jobs represent more than just numbers; they are the lifeblood of local families, providing stable careers and contributing to the overall economic health of Lima and Allen County. The sector's significant presence underscores the community's long-standing tradition of industrial excellence and adaptability in a changing economic environment.

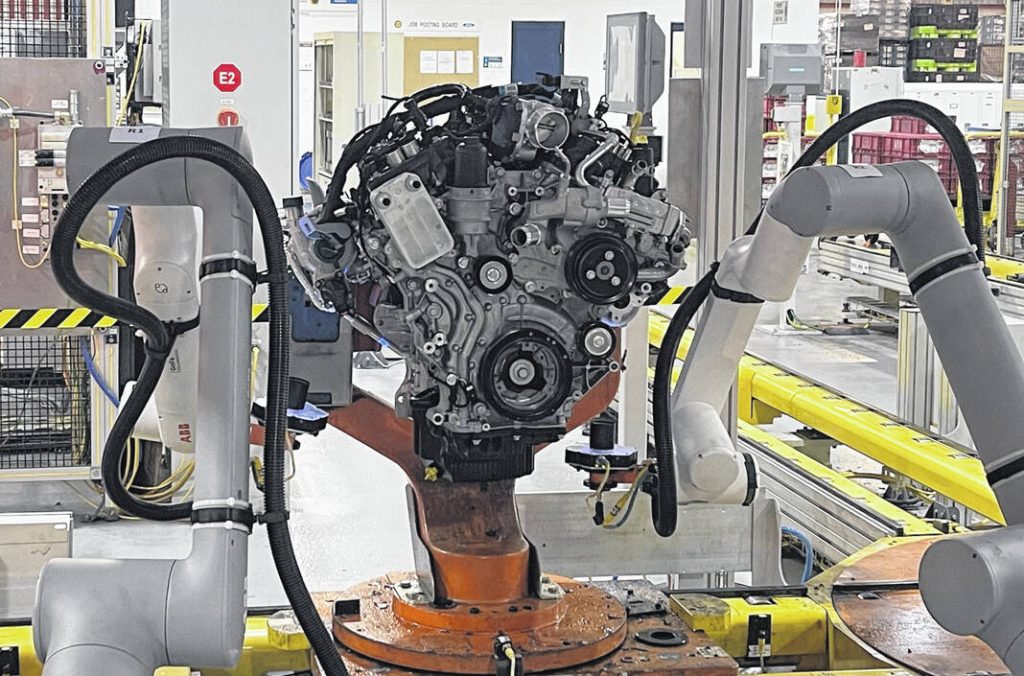

Revolutionizing Manufacturing: The Rise of Collaborative Robotics in Lima's Industrial Landscape

In the heart of Ohio's industrial corridor, Lima stands as a testament to American manufacturing prowess, where technological innovation and human expertise converge to reshape the economic foundation of the region. The manufacturing sector continues to be a critical driver of economic growth, employment, and technological advancement, presenting a dynamic landscape of opportunity and transformation.Powering Economic Resilience Through Cutting-Edge Industrial Innovation

The Technological Metamorphosis of Manufacturing

The manufacturing ecosystem in Lima and Allen County represents a complex and evolving industrial tapestry that extends far beyond traditional production methodologies. Modern manufacturing has transcended its historical boundaries, embracing sophisticated technological integrations that fundamentally reimagine workplace productivity and operational efficiency. Collaborative robots, or cobots, have emerged as a pivotal technological breakthrough, bridging the gap between human creativity and mechanical precision. These advanced robotic systems are not merely replacing human workers but are strategically augmenting human capabilities, creating a symbiotic relationship that enhances overall productivity. By handling repetitive, physically demanding tasks, cobots enable human workers to focus on more complex, strategic, and creative aspects of manufacturing processes.Economic Impact and Workforce Transformation

The integration of collaborative robotics represents a profound shift in the regional economic landscape. With 19.3 percent of local workers employed in manufacturing, the adoption of cobot technologies signals a significant transformation in workforce dynamics. This technological revolution is not about displacement but about upskilling and creating more sophisticated employment opportunities. Companies in Lima are discovering that cobots can dramatically improve workplace safety, reduce repetitive strain injuries, and increase overall production efficiency. These robotic assistants can work alongside human employees with unprecedented precision, adapting to complex manufacturing environments with remarkable flexibility.Technological Innovation and Regional Competitiveness

Lima's manufacturing sector is positioning itself at the forefront of technological innovation by embracing collaborative robotics. This strategic approach ensures regional competitiveness in an increasingly global marketplace. By investing in advanced technologies, local manufacturers are not just maintaining their current market position but actively creating pathways for future growth and development. The implementation of cobots requires significant investment in workforce training, creating a multiplier effect that extends beyond immediate manufacturing processes. Educational institutions and local industries are developing collaborative programs to prepare the next generation of technologically adept manufacturing professionals.Sustainable Manufacturing and Future Prospects

The integration of collaborative robotics represents more than a technological upgrade; it embodies a comprehensive approach to sustainable manufacturing. These advanced systems contribute to reduced waste, improved energy efficiency, and more precise production processes. By minimizing human error and optimizing operational workflows, cobots are helping local manufacturers reduce their environmental footprint while maintaining high-quality output. As Lima continues to evolve its manufacturing ecosystem, the synergy between human expertise and robotic precision promises a future of unprecedented innovation, economic resilience, and technological leadership in the industrial sector.RELATED NEWS

Manufacturing

Revolution on the Factory Floor: How Next-Gen Tech is Reshaping OEM Supply Chains

2025-04-07 05:07:14

Manufacturing

Bringing Jobs Home: Therabody's Strategic Pause on Full US Manufacturing

2025-04-28 12:06:51

Manufacturing

Investment Shift: Ruffer LLP Trims Stake in Tech Giant Taiwan Semiconductor

2025-03-09 11:55:24