Breaking: Tech's New Countdown - When Presets Become Launchpads

Manufacturing

2025-04-02 17:25:00Content

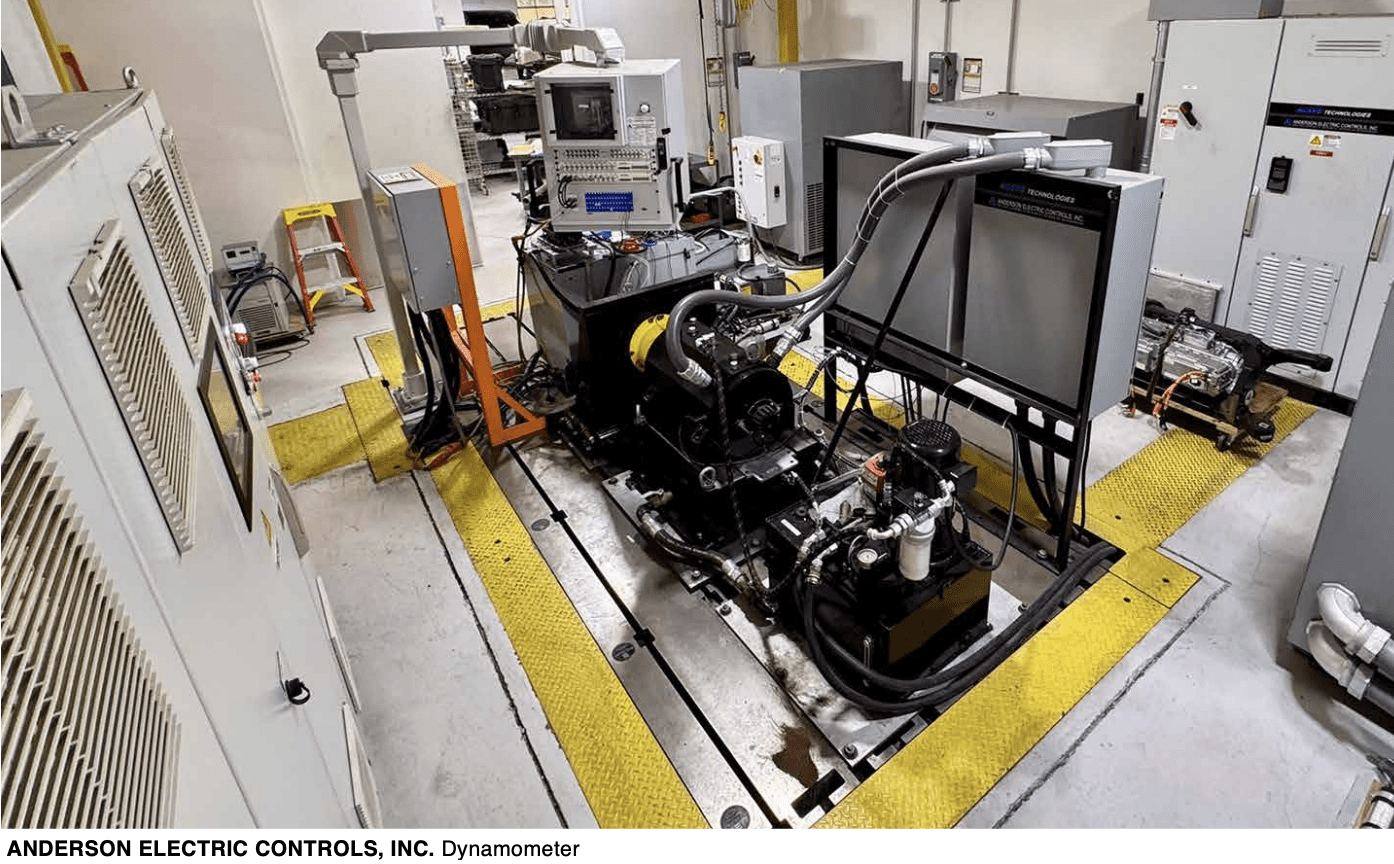

In the competitive landscape of modern manufacturing, shops are constantly seeking innovative solutions to overcome challenges. The twin pressures of a skilled labor shortage and the critical need to minimize setup times have created a compelling case for offline tool presetters.

These sophisticated devices are no longer a luxury, but a strategic necessity for manufacturers looking to boost efficiency and productivity. By allowing precise tool measurement and preparation outside of the primary machining equipment, offline presetters offer a game-changing approach to workflow optimization.

Imagine reducing machine downtime, improving tool accuracy, and streamlining your entire production process—all while addressing the ongoing skilled labor constraints. Offline tool presetters provide manufacturers with a powerful tool to achieve these goals, enabling faster changeovers, more consistent tool performance, and ultimately, a more competitive manufacturing operation.

For shops seeking to stay ahead in a rapidly evolving industrial landscape, investing in offline tool presetters isn't just a smart choice—it's becoming an essential strategy for success.

Revolutionizing Manufacturing: The Game-Changing Power of Offline Tool Presetters

In the rapidly evolving landscape of modern manufacturing, businesses are constantly seeking innovative solutions to overcome persistent challenges. The intersection of technological advancement and workforce dynamics has created a critical need for strategic approaches that can simultaneously address skill shortages and operational efficiency.Transforming Workshop Productivity: A Critical Manufacturing Solution

The Skilled Labor Conundrum in Modern Manufacturing

Manufacturing industries worldwide are grappling with an unprecedented skilled labor shortage that threatens operational continuity and competitive edge. This complex challenge extends beyond mere recruitment difficulties, representing a fundamental transformation in workforce dynamics. Manufacturers must now develop sophisticated strategies that leverage technology to bridge the expertise gap, maximizing productivity with fewer human resources. The traditional model of manufacturing workforce development has become increasingly obsolete. As experienced technicians retire and younger generations demonstrate different career preferences, companies must reimagine their approach to skill acquisition and operational efficiency. Advanced technological solutions like offline tool presetters emerge as a critical intervention, offering a sophisticated mechanism to mitigate labor constraints.Technological Innovation: Offline Tool Presetters as a Strategic Solution

Offline tool presetters represent a revolutionary technological intervention in manufacturing workflows. These sophisticated devices enable precise tool preparation and measurement outside of primary manufacturing equipment, dramatically reducing machine downtime and enhancing overall operational efficiency. By allowing comprehensive tool setup and verification in a dedicated workspace, manufacturers can streamline their production processes with unprecedented precision. The strategic implementation of offline tool presetters delivers multifaceted benefits. Beyond minimizing setup times, these systems provide enhanced measurement accuracy, reduce potential human error, and create a more standardized approach to tool preparation. Manufacturers can effectively transform their operational paradigm, converting potential productivity bottlenecks into streamlined, predictable processes.Economic and Operational Implications of Advanced Presetting Technologies

The economic rationale for adopting offline tool presetters extends far beyond immediate operational improvements. By reducing machine setup times, manufacturers can significantly increase overall equipment effectiveness (OEE), translating directly into improved profitability and competitive advantage. The ability to prepare tools with minimal machine interruption represents a fundamental shift in manufacturing philosophy. Moreover, these technologies provide comprehensive data collection and analysis capabilities. Modern offline tool presetters are often equipped with advanced digital interfaces that capture critical measurement data, enabling continuous process improvement and more informed decision-making. This data-driven approach transforms tool preparation from a purely mechanical task into a strategic operational function.Future-Proofing Manufacturing Through Technological Integration

As manufacturing continues to evolve, technological integration becomes increasingly paramount. Offline tool presetters symbolize a broader trend toward intelligent, adaptive manufacturing systems that can respond dynamically to changing operational requirements. By investing in such technologies, manufacturers position themselves at the forefront of industrial innovation. The convergence of precision engineering, digital technology, and strategic workforce management creates unprecedented opportunities for manufacturing organizations. Offline tool presetters are not merely technological solutions but represent a holistic approach to addressing contemporary manufacturing challenges, bridging human expertise with technological capability.RELATED NEWS

Manufacturing

Manufacturing Titans Converge: Chippewa Falls Set to Host Groundbreaking Industry Showcase

2025-03-26 17:30:00

Manufacturing

Factory Fortunes: 5 Manufacturing Stocks Poised to Surge in Today's Market

2025-03-09 18:03:19

Manufacturing

Reviving the Factory Floor: Entrepreneurs' Bold Blueprint for American Manufacturing Renaissance

2025-04-15 10:00:00