Trade Tensions Loom: How Trump's Tariffs Are Reshaping Mexico's Manufacturing Landscape in El Paso

Manufacturing

2025-03-28 13:57:12Content

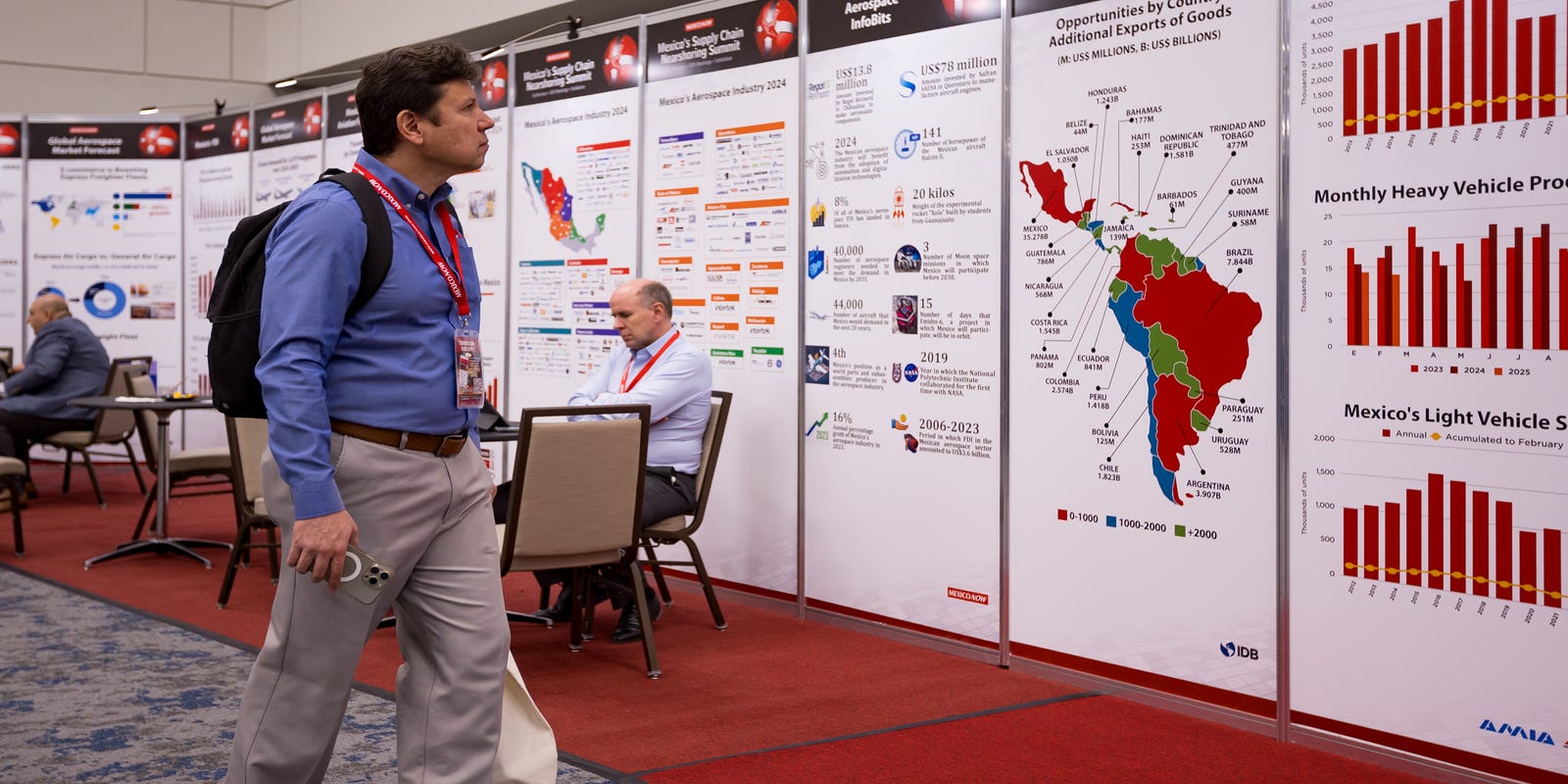

At the annual El Paso manufacturing trade show, tension hung thick in the air as suppliers to Mexican factories expressed growing concerns about potential tariffs proposed by former President Donald Trump, with the automotive industry bracing for the most significant impact.

Automotive supply chain professionals gathered in hushed conversations, analyzing the potential economic ripple effects of Trump's pending trade restrictions. The mood was a mix of uncertainty and apprehension, as manufacturers and suppliers contemplated how these proposed tariffs could dramatically reshape cross-border manufacturing relationships.

Industry experts warned that the proposed tariffs could disrupt the intricate and interconnected supply chains between the United States and Mexico, potentially increasing production costs and challenging the competitive advantage of manufacturing in the region. The automotive sector, in particular, stood at the forefront of these discussions, given its complex international manufacturing networks.

Suppliers from both sides of the border shared anxious perspectives, highlighting the potential economic challenges that could arise from increased trade barriers. The trade show became a critical platform for discussing strategies to mitigate potential financial risks and maintain the robust manufacturing ecosystem that has developed between the two countries.

Navigating Uncertainty: Mexico's Manufacturing Sector Braces for Potential Trump-Era Trade Disruptions

In the dynamic landscape of international trade, Mexico's manufacturing industry finds itself at a critical crossroads, with potential policy shifts threatening to reshape the intricate supply chain ecosystem that has been carefully cultivated over decades. The annual manufacturing trade show in El Paso serves as a pivotal platform for suppliers, industry leaders, and policymakers to confront the looming challenges and strategize for an increasingly unpredictable economic environment.Transformative Tensions in Cross-Border Manufacturing Dynamics

The Automotive Industry's Precarious Position

The automotive sector stands at the epicenter of potential trade disruptions, with suppliers expressing profound apprehension about the potential reimplementation of punitive tariffs. Mexico's manufacturing landscape has historically relied on intricate cross-border supply chains, particularly within the automotive industry, where complex manufacturing networks span multiple international boundaries. The potential for targeted tariffs threatens to unravel decades of carefully constructed economic interdependence, potentially forcing manufacturers to reevaluate their entire operational strategies. Experts at the trade show highlighted the delicate balance of international manufacturing relationships, emphasizing that any sudden policy shifts could trigger cascading economic consequences. The automotive industry, which has been a cornerstone of Mexico's manufacturing prowess, could face significant restructuring, potentially impacting thousands of jobs and billions in economic output.Economic Resilience and Strategic Adaptation

Mexican manufacturers are not merely passive recipients of potential policy changes but are actively developing sophisticated contingency strategies. The trade show revealed a remarkable level of strategic planning, with industry leaders discussing innovative approaches to mitigate potential economic disruptions. These strategies range from diversifying supply chains to exploring alternative international partnerships and investing in advanced technological capabilities. The potential for tariff implementations has accelerated discussions about technological innovation and operational flexibility. Manufacturers are increasingly viewing uncertainty as an opportunity for transformation, investing in automation, digital infrastructure, and advanced manufacturing techniques that could potentially insulate them from traditional trade barriers.Geopolitical Implications and Trade Negotiations

Beyond immediate economic concerns, the trade show underscored the complex geopolitical dynamics influencing international manufacturing. Discussions extended beyond immediate tariff concerns, exploring broader themes of economic sovereignty, technological competition, and the evolving nature of global trade relationships. Diplomatic representatives and trade experts engaged in nuanced dialogues about potential negotiation strategies, emphasizing the need for collaborative approaches that balance national economic interests with international economic interdependence. The conversations reflected a sophisticated understanding that modern trade relationships require flexibility, mutual understanding, and strategic long-term thinking.Technological Innovation as a Competitive Advantage

Technological innovation emerged as a critical theme, with many manufacturers viewing advanced technological capabilities as a potential shield against traditional trade barriers. Discussions centered on how investments in artificial intelligence, robotics, and advanced manufacturing technologies could create competitive advantages that transcend traditional economic limitations. The trade show became a crucible of technological exchange, with companies showcasing cutting-edge manufacturing technologies that could potentially revolutionize traditional production methodologies. These innovations represent more than mere technological upgrades; they symbolize a fundamental reimagining of manufacturing's future in an increasingly complex global landscape.Workforce Development and Economic Adaptation

The potential for trade disruptions has profound implications for workforce development. Manufacturers are increasingly investing in comprehensive training programs, recognizing that human capital represents the most critical asset in navigating uncertain economic terrain. Educational institutions and industry partners are collaborating to develop adaptive workforce strategies, creating training programs that emphasize technological literacy, flexibility, and cross-disciplinary skills. These initiatives represent a proactive approach to potential economic challenges, focusing on creating a workforce capable of thriving amid uncertainty.RELATED NEWS

Manufacturing

Cook Praises Trump's Silicon Strategy: A Boost for American Chip Production

2025-05-02 12:55:58

Manufacturing

Dragon vs. Elephant: India's Industrial Surge Threatens China's Manufacturing Crown

2025-05-06 17:20:46

Manufacturing

Grid Revolution: Switched Source Pumps $5M into Cutting-Edge Manufacturing Hub

2025-03-20 10:00:00