Inferno Disrupts: Aerospace Giants Reel from Catastrophic Factory Blaze

Manufacturing

2025-02-27 21:14:25Content

In the wake of a devastating fire at a critical parts manufacturing facility near Philadelphia, aerospace giants like Boeing are conducting urgent and meticulous investigations into their supply chain vulnerabilities. Industry insiders reveal that top aerospace companies are working diligently to assess the potential disruptions and risks stemming from the recent factory blaze.

The unexpected industrial incident has sent shockwaves through the aerospace sector, prompting immediate and comprehensive supply chain reviews. Executives and supply chain managers are working around the clock to understand the full scope of potential component shortages and manufacturing delays that could impact aircraft production and maintenance.

With precision and concern, these companies are mapping out their dependencies on the affected factory, evaluating alternative sourcing strategies, and developing contingency plans to mitigate potential disruptions. The fire has underscored the fragility of complex manufacturing networks and the critical importance of supply chain resilience in the high-stakes aerospace industry.

As investigations continue and the full impact becomes clearer, aerospace firms are demonstrating their commitment to maintaining operational continuity and ensuring the highest standards of safety and reliability.

Supply Chain Shockwaves: Aerospace Giants Scramble After Philadelphia Factory Inferno

In the high-stakes world of aerospace manufacturing, a single incident can send ripple effects through an entire industry. The recent catastrophic fire at a critical parts factory near Philadelphia has thrust major aerospace corporations into a state of urgent investigation and strategic reassessment, highlighting the delicate interconnectedness of global supply chains.Unraveling the Industrial Disruption: When Flames Threaten Precision Engineering

The Immediate Industrial Impact

The devastating fire that erupted in the Philadelphia metropolitan area has triggered an unprecedented wave of concern among top-tier aerospace manufacturers. Companies like Boeing are now conducting meticulous and comprehensive investigations into their supply network vulnerabilities, recognizing that a single manufacturing disruption can potentially compromise entire production ecosystems. Aerospace engineering relies on intricate, precisely calibrated supply chains where each component represents a critical link. The factory blaze has exposed potential systemic weaknesses that could reverberate through multiple manufacturing pipelines, compelling corporations to reevaluate their risk management strategies and contingency planning.Supply Chain Vulnerability Assessment

Industry experts are now intensely scrutinizing the interconnected networks that sustain aerospace manufacturing. The Philadelphia factory incident serves as a stark reminder of how fragile these complex systems can be, with even a localized disruption capable of generating widespread operational challenges. Manufacturers are deploying advanced diagnostic tools and cross-referencing procurement databases to understand the full extent of potential component shortages. This forensic approach involves tracing every potential supply route, assessing alternative sourcing strategies, and developing rapid response mechanisms to mitigate potential production interruptions.Technological Resilience and Adaptive Strategies

The current crisis is compelling aerospace companies to invest in more robust, flexible supply chain architectures. Advanced predictive analytics, real-time monitoring systems, and diversified sourcing strategies are emerging as critical tools in building more resilient industrial ecosystems. By developing multi-tiered supplier networks and implementing sophisticated risk management protocols, aerospace manufacturers aim to create more adaptable production frameworks. These strategies go beyond traditional contingency planning, representing a fundamental reimagining of industrial supply chain dynamics.Economic and Operational Implications

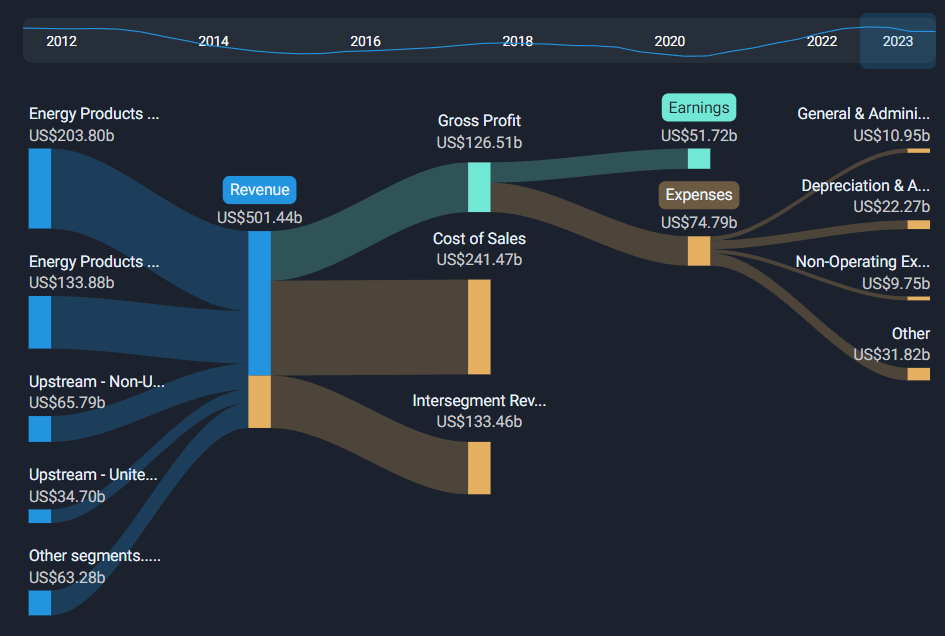

The Philadelphia factory fire transcends a mere localized incident, potentially signaling broader challenges within advanced manufacturing sectors. Investors, industry analysts, and corporate strategists are closely monitoring how major aerospace corporations navigate this complex disruption. Financial markets have already begun reflecting the potential downstream effects, with stock prices of key manufacturers experiencing subtle but noticeable fluctuations. The incident underscores the critical importance of supply chain redundancy and rapid adaptive capabilities in maintaining operational continuity.Regulatory and Safety Considerations

Regulatory bodies are likely to intensify scrutiny of manufacturing safety protocols in the wake of this incident. The aerospace industry, known for its stringent safety standards, will face increased pressure to demonstrate robust risk mitigation strategies and comprehensive emergency response mechanisms. Investigations will likely focus not just on the immediate cause of the fire, but on broader systemic vulnerabilities that could compromise industrial infrastructure. This may lead to enhanced safety regulations and more comprehensive risk assessment frameworks across manufacturing sectors.RELATED NEWS

Manufacturing

Manufacturing's Digital Revolution: Cloud MES Market Set to Explode to $24B, Tech Titans Battle for Supremacy

2025-03-13 11:43:00

Manufacturing

Forging Ahead: The Unexpected Forces Revitalizing U.S. Manufacturing

2025-04-09 13:02:04

Manufacturing

Panasonic Malaysia's Earnings Slide: Profit Dips 22% in Q3 2025, Investors Take Note

2025-03-03 00:33:30