Robots Rising: Figure AI's Massive Humanoid Factory Signals New Era of AI Manufacturing

Manufacturing

2025-03-20 21:24:15Content

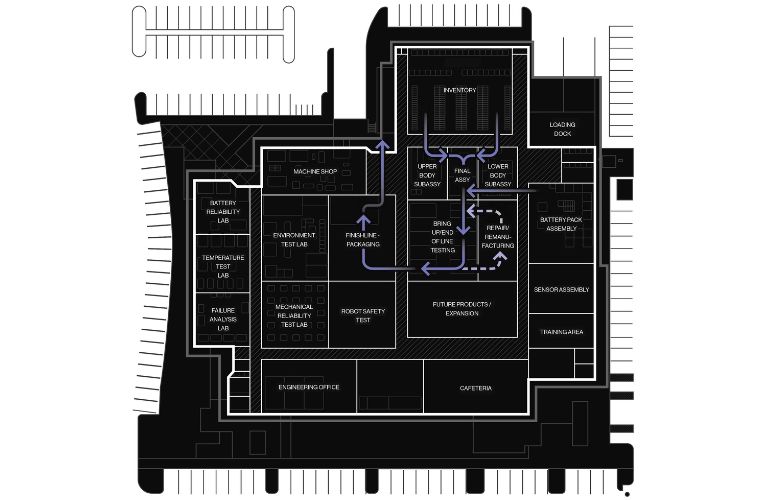

Figure AI, a pioneering robotics company, has announced a strategic shift in its humanoid robot production, bringing manufacturing operations in-house. This bold move is aimed at gaining unprecedented control over the build process and ensuring superior quality standards for their advanced humanoid robots.

By internalizing the manufacturing process, Figure AI demonstrates its commitment to precision engineering and meticulous quality control. This approach allows the company to directly oversee every stage of production, from component selection to final assembly, ultimately enhancing the reliability and performance of their cutting-edge humanoid technologies.

The decision to manage manufacturing internally reflects Figure AI's dedication to innovation and its vision of creating highly sophisticated, dependable robotic systems that can seamlessly integrate into various industrial and technological environments.

Revolutionizing Humanoid Manufacturing: Figure AI's Bold In-House Strategy Unveiled

In the rapidly evolving landscape of artificial intelligence and robotics, Figure AI emerges as a pioneering force, challenging traditional manufacturing paradigms with an unprecedented approach to humanoid robot development. The company's strategic decision to internalize its manufacturing processes represents a watershed moment in the technological frontier, signaling a profound commitment to innovation and quality control.Transforming Robotics: Where Innovation Meets Precision

The Strategic Shift in Humanoid Production

Figure AI's groundbreaking decision to bring manufacturing in-house marks a transformative moment in robotic engineering. By assuming complete control over the production ecosystem, the company eliminates external dependencies and creates a tightly integrated development pipeline. This approach allows for unprecedented levels of quality assurance and technological refinement, enabling engineers to implement rapid iterations and sophisticated design modifications with remarkable agility. The vertical integration strategy represents more than a mere manufacturing choice—it's a comprehensive reimagining of how humanoid robots are conceptualized, developed, and brought to market. By maintaining direct oversight of every production stage, Figure AI can ensure that each robotic unit meets exacting standards of performance, durability, and technological sophistication.Technological Implications of In-House Manufacturing

The move towards internal manufacturing unlocks extraordinary potential for technological innovation. By eliminating intermediary manufacturers, Figure AI creates a direct conduit between conceptual design and physical implementation. This approach allows for unprecedented levels of precision engineering, with design teams able to immediately translate theoretical concepts into tangible robotic prototypes. Engineers can now experiment with cutting-edge materials, advanced sensor technologies, and complex mechanical architectures without the traditional constraints imposed by external manufacturing partners. The result is a more dynamic, responsive approach to humanoid robot development that prioritizes continuous improvement and technological breakthrough.Quality Control and Technological Excellence

In-house manufacturing provides Figure AI with comprehensive quality control mechanisms that far surpass traditional industry standards. By maintaining direct oversight of every production stage, the company can implement rigorous testing protocols, ensuring that each humanoid robot meets extraordinary performance benchmarks. The ability to conduct immediate, granular quality assessments means potential design flaws can be identified and rectified instantaneously. This approach dramatically reduces production cycles and minimizes the risk of technological compromise, positioning Figure AI at the forefront of robotic innovation.Economic and Strategic Advantages

Beyond technological considerations, the in-house manufacturing strategy offers significant economic advantages. By internalizing production processes, Figure AI can optimize resource allocation, reduce external dependencies, and create a more streamlined, cost-effective development model. The approach also provides enhanced intellectual property protection, ensuring that proprietary technologies remain securely within the company's ecosystem. This strategic advantage allows Figure AI to maintain a competitive edge in the increasingly complex landscape of advanced robotics.Future Outlook and Technological Potential

Figure AI's bold manufacturing strategy signals a potential paradigm shift in robotic development. By demonstrating the viability of comprehensive in-house production, the company opens new horizons for technological innovation, challenging existing industry assumptions and setting new standards for precision engineering. As artificial intelligence and robotics continue to evolve, Figure AI's approach represents a visionary model of technological development—one that prioritizes direct control, continuous innovation, and uncompromising quality. The implications extend far beyond current technological boundaries, promising a future where humanoid robots become increasingly sophisticated, adaptable, and transformative.RELATED NEWS

Manufacturing

Putin Breaks Silence: Russia's Arsenal Falls Short in Manufacturing Crunch

2025-04-23 12:45:06

Manufacturing

Precision Meets Innovation: Midland's Digital Breakthrough Transforms Railcar Measurement

2025-04-15 20:15:00

Manufacturing

Innovators Triumph: A' Design Awards Unveil Groundbreaking Manufacturing Excellence for 2024

2025-03-14 07:47:37