Composite Manufacturing Revolution: Reinforce 3D and Spring Srl Unite to Reshape Industry Dynamics

Manufacturing

2025-03-11 14:23:04Content

Revolutionary CFIP Technology: Reinforce 3D and Spring Redefine Composite Materials

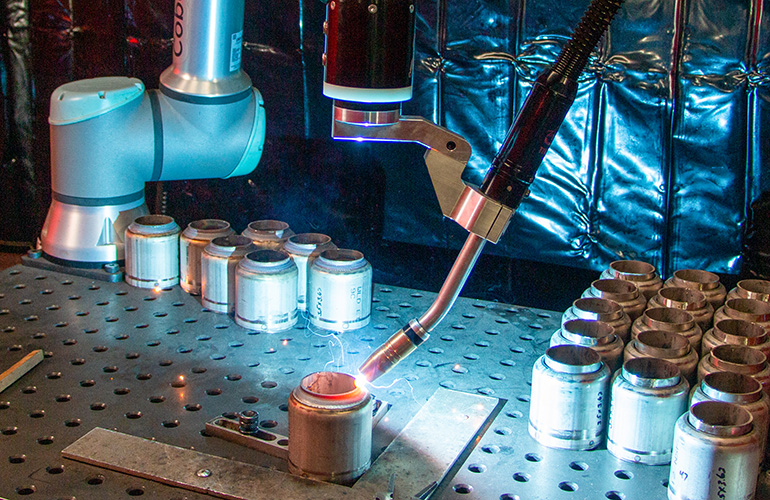

In the cutting-edge world of advanced materials engineering, Reinforce 3D and Spring are pushing the boundaries of innovation with their groundbreaking Continuous Fiber Insertion Printing (CFIP) technology. This revolutionary approach is set to transform how high-performance composite materials are designed, manufactured, and applied across multiple industries.

CFIP represents a quantum leap in material science, offering unprecedented precision and performance. By seamlessly integrating continuous fibers directly into the manufacturing process, these companies are creating composite materials with exceptional strength, lightweight characteristics, and remarkable structural integrity.

The technology's potential is immense, promising to revolutionize sectors ranging from aerospace and automotive to robotics and advanced manufacturing. Engineers and designers can now access materials that were previously impossible to create, opening up new frontiers of design and engineering possibilities.

What sets Reinforce 3D and Spring apart is their commitment to pushing technological boundaries. Their CFIP approach allows for complex geometries, enhanced material properties, and more efficient production methods that were unimaginable just a few years ago.

As industries continue to demand higher performance and greater efficiency, innovations like CFIP are not just improvements—they're transformative technologies that will shape the future of material engineering.

Revolutionary Composite Materials: The Future of High-Performance Manufacturing Unveiled

In the rapidly evolving landscape of advanced manufacturing, groundbreaking technologies are reshaping our understanding of material science and engineering. The convergence of cutting-edge research and innovative design is pushing the boundaries of what's possible in composite material development, with companies like Reinforce 3D and Spring leading the charge in transformative technological breakthroughs.Unleashing the Power of Next-Generation Composite Innovation

The Emergence of CFIP Technology: A Paradigm Shift in Material Engineering

The Composite Fiber Integrated Processing (CFIP) technology represents a quantum leap in material science, fundamentally reimagining how high-performance composites are conceptualized, developed, and manufactured. Unlike traditional manufacturing approaches, CFIP introduces a holistic methodology that integrates advanced computational modeling, precision engineering, and material science principles. At its core, this revolutionary technology enables unprecedented levels of material customization, allowing engineers to design composites with microscopic precision. By manipulating fiber orientation, matrix composition, and structural integrity at the molecular level, researchers can create materials with extraordinary performance characteristics that were previously unimaginable.Technological Foundations of Advanced Composite Manufacturing

The intricate process behind CFIP technology involves multiple sophisticated stages of material development. Advanced computational algorithms analyze potential material configurations, simulating performance under diverse environmental conditions. This predictive modeling allows engineers to optimize material properties before physical production, dramatically reducing research and development cycles. Sophisticated manufacturing techniques, including precision fiber placement, nano-scale reinforcement, and intelligent matrix integration, enable the creation of composites with remarkable strength-to-weight ratios. These materials exhibit exceptional resistance to mechanical stress, temperature variations, and environmental degradation, making them ideal for aerospace, automotive, and advanced engineering applications.Industrial Implications and Transformative Potential

The introduction of CFIP technology signals a profound transformation across multiple industrial sectors. Aerospace manufacturers can develop lighter, more fuel-efficient aircraft components, while automotive engineers can create vehicles with enhanced safety and performance characteristics. The medical device industry stands to benefit from materials with unprecedented biocompatibility and structural integrity. Economic implications are equally significant. By reducing material waste, optimizing production processes, and enabling more sophisticated design capabilities, CFIP technology represents a potential multi-billion dollar opportunity for forward-thinking manufacturers. The ability to create custom-engineered materials with precise performance specifications opens new frontiers of innovation.Research and Development: Pushing Technological Boundaries

Continuous research remains critical to advancing CFIP technology. Interdisciplinary teams of materials scientists, computational experts, and engineering specialists are collaborating to unlock new potential. Emerging research focuses on developing even more sophisticated computational models, exploring quantum-level material interactions, and creating adaptive composite structures. Machine learning algorithms are increasingly being integrated into the development process, enabling more rapid iteration and discovery. These intelligent systems can analyze vast datasets, identifying subtle material performance patterns that human researchers might overlook, thereby accelerating technological progress.Global Market Perspectives and Future Outlook

The global market for advanced composite materials is projected to experience exponential growth in the coming decades. Industry analysts predict that technologies like CFIP will play a pivotal role in driving innovation across manufacturing, transportation, and technology sectors. Companies investing in research and development today are positioning themselves at the forefront of this technological revolution. International collaborations and strategic partnerships will be crucial in translating laboratory breakthroughs into commercial applications. As global competition intensifies, nations and corporations that successfully leverage advanced composite technologies will gain significant strategic advantages in the high-tech manufacturing landscape.RELATED NEWS

Electric Vehicle Supply Chain Booms: Component Makers Ride the Green Revolution Wave

Breaking: Revolutionary Contraceptive PHEXXI Slashes Prices, Opens Doors to Affordable Family Planning