Robots, Reimagined: How Collaborative Machines Are Revolutionizing Manufacturing Efficiency

Manufacturing

2025-02-28 19:27:11Content

Discover the Future of Manufacturing: Collaborative Robots (Cobots) Unveiled

Join us for an illuminating webinar that demystifies collaborative robotics and transforms your understanding of modern manufacturing technology. This free, comprehensive session will take you deep into the world of cobots, exploring their revolutionary impact on industrial processes.

What You'll Learn:

- Core concepts and fundamental principles of collaborative robotics

- Real-world applications across diverse manufacturing environments

- Critical safety protocols and best practices

- Tangible business benefits and competitive advantages

Whether you're an engineering professional, manufacturing manager, or technology enthusiast, this webinar offers invaluable insights into how collaborative robots are reshaping industrial automation. Don't miss this opportunity to stay ahead of the technological curve and understand the transformative potential of cobots.

Register now for this free, must-attend webinar and unlock the future of smart manufacturing!

Revolutionizing Manufacturing: The Collaborative Robot (Cobot) Transformation

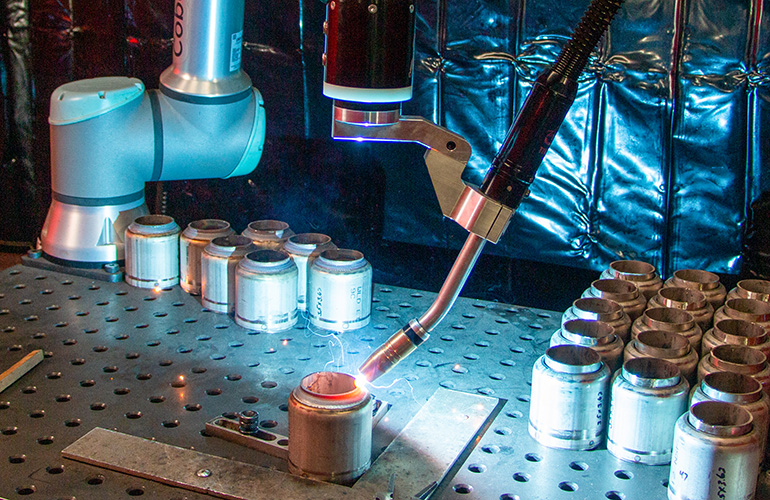

In the rapidly evolving landscape of industrial automation, collaborative robots, or cobots, are emerging as a game-changing technology that promises to redefine the manufacturing ecosystem. These intelligent machines represent a paradigm shift from traditional industrial robots, offering unprecedented flexibility, safety, and efficiency for businesses seeking to optimize their production processes.Unlock the Future of Smart Manufacturing with Cutting-Edge Robotic Collaboration

The Evolution of Robotic Technology in Modern Manufacturing

The manufacturing sector has witnessed a remarkable transformation over the past decade, with collaborative robots standing at the forefront of this technological revolution. Unlike their predecessors, cobots are designed to work alongside human workers, creating a symbiotic relationship that enhances productivity and workplace safety. These advanced machines leverage sophisticated sensors, artificial intelligence, and adaptive learning capabilities to seamlessly integrate into existing production environments. Modern cobots represent a quantum leap in industrial automation, featuring intuitive programming interfaces that allow even non-technical personnel to configure and deploy robotic systems. Their lightweight design and advanced force-sensing technologies enable them to operate in close proximity to human workers without requiring extensive safety barriers, fundamentally reimagining workplace dynamics.Safety Innovations in Collaborative Robotics

Safety remains the paramount concern in any manufacturing environment, and cobots have been engineered with this critical consideration at their core. Advanced collision detection systems, real-time force monitoring, and programmable safety zones ensure that these robots can instantly detect and respond to potential human interactions, dramatically reducing workplace accidents. The intricate safety mechanisms of collaborative robots go beyond traditional mechanical safeguards. Sophisticated algorithms continuously analyze workspace dynamics, predicting potential collision risks and implementing immediate protective measures. This proactive approach transforms workplace safety from a reactive to a predictive model, creating environments where human and machine collaboration becomes seamless and inherently secure.Economic and Operational Benefits of Cobot Integration

Implementing collaborative robots offers manufacturers a compelling value proposition that extends far beyond traditional automation strategies. These versatile machines provide unprecedented flexibility, enabling businesses to rapidly reconfigure production lines, adapt to changing market demands, and optimize resource allocation with minimal downtime. The economic advantages of cobots are multifaceted. By reducing labor-intensive tasks, businesses can redeploy human workers towards more strategic, value-added activities. The initial investment in cobot technology is typically recovered within months through increased productivity, reduced error rates, and enhanced operational efficiency. Moreover, these robots operate with remarkable precision, consistently maintaining high-quality output standards that human workers might find challenging to replicate.Technological Capabilities and Future Potential

Contemporary collaborative robots are equipped with an impressive array of technological capabilities that extend well beyond basic manufacturing tasks. Machine learning algorithms enable these systems to continuously improve performance, adapt to complex operational scenarios, and develop increasingly sophisticated interaction protocols with human colleagues. Vision recognition systems, advanced tactile sensors, and cloud-connected diagnostics represent the cutting edge of cobot technology. These innovations allow robots to perform intricate tasks with human-like dexterity, from delicate assembly processes to complex quality control inspections. As artificial intelligence continues to advance, the potential applications for collaborative robots will expand exponentially, promising a future where human creativity and robotic precision converge seamlessly.Industry-Specific Applications and Transformative Potential

The versatility of collaborative robots transcends traditional manufacturing boundaries, finding applications across diverse industrial sectors. From automotive assembly lines to pharmaceutical research facilities, cobots are revolutionizing operational paradigms by offering unprecedented flexibility and precision. In electronics manufacturing, these robots handle microscopic components with nanometer-level accuracy. Agricultural sectors utilize cobots for precision planting and harvesting, while medical device manufacturers leverage their capabilities for intricate assembly processes. Each industry discovers unique ways to integrate these technological marvels, demonstrating the transformative potential of collaborative robotics.RELATED NEWS

3D Printing Revolution: How Healthcare Innovators Are Reshaping Medical Manufacturing by 2032

Job Cuts Hit Waterbury: Rheem Manufacturing to Downsize Workforce by 76 Employees